Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

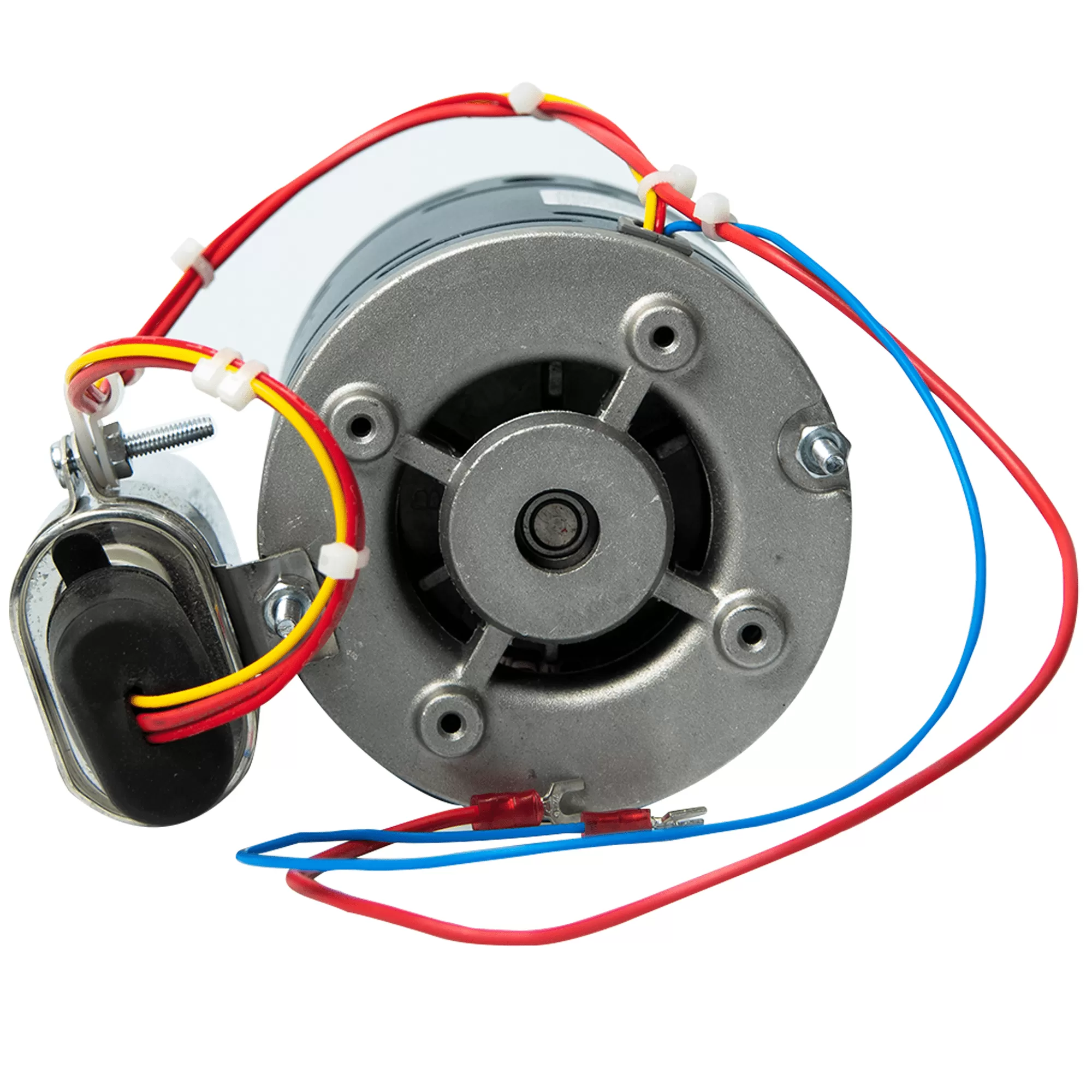

Motor Assembly

- Home

- portfolio

- Industrial Automation

- Motor Assembly

Case Study: Design and Manufacturing of a Motor Assembly for Industrial Automation

Published: February 5, 2020, Category: Industrial Automation

Overview

A leading manufacturer of industrial automation equipment approached us with a requirement for a compact, high-efficiency motor assembly to be integrated into their next-generation robotic actuator system. The motor assembly needed to meet tight tolerances, deliver high torque in a small footprint, and operate reliably under continuous-duty cycles.

Project Requirements

- Compact design with minimal weight.

- High torque output with low noise levels.

- Integrated gearbox for torque multiplication.

- Sensor feedback for precise control.

- Robust housing for harsh industrial environments.

- Thermal management and vibration resistance.

- Manufacturability at medium production volumes.

Design & Engineering Approach

1. Concept Development

- Multiple motor types were evaluated: BLDC (Brushless DC), stepper, and servo motors.

- A BLDC motor with integrated planetary gearbox was selected for its balance of performance, size, and efficiency.

- CAD models were created for motor, housing, and interface components.

2. Component Selection

- High-energy neodymium magnets for the rotor.

- Custom stator winding optimized for torque-density.

- Low-backlash planetary gearbox (4:1 ratio).

- Optical encoder for precise speed/position feedback.

- Thermally conductive but electrically insulating materials for heat dissipation.

3. Prototyping

- Rapid prototyping via CNC machining and 3D printing.

- Performance validated using in-house dynamometer testing.

- Modifications made to improve torque response and reduce vibration.

4. Electronics Integration

- Custom motor driver PCB developed with overcurrent, thermal, and stall protection.

- Integrated sensor inputs and CANopen communication protocol.

5. Mechanical Design & Manufacturing

- Aluminum housing designed for efficient heat sinking and structural integrity.

- All assemblies performed in-house with precision alignment tools.

- Tested to withstand IP54 environmental conditions.

Testing & Validation

- Torque-speed characterization under variable loads.

- Thermal cycling to verify reliability over time.

- Shock and vibration tests per IEC standards.

- EMC compliance to meet CE certification.

Results

- Final motor assembly delivered 30% higher torque than previous design.

- Achieved 15% reduction in overall size and weight.

- Met all thermal and noise specifications.

- Successful integration into client’s robotic actuator system.

- Scaled to production volumes of 500 units/month within 90 days.

Conclusion

This project demonstrated our full-scope capabilities—from initial concept through prototyping, validation, and manufacturing. The success of the motor assembly design directly contributed to the client’s product launch, providing them with a performance edge in the competitive automation market.