Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top Trends in Wire Harness Assembly for 2025: What You Need to Know

As we look towards 2025, the wire harness assembly industry is poised for significant transformation driven by technological advancements and evolving market demands. Experts in the field, such as Dr. Emily Carter, a leading authority in electrical engineering and wire harness innovations, emphasize the importance of adaptability in today's fast-paced environment. She states, “The future of wire harness assembly lies in the integration of smart technologies that enhance efficiency and accuracy in production.”

In this rapidly changing landscape, industry stakeholders must stay informed about the latest trends that are reshaping wire harness assembly processes. The growing emphasis on automation, sustainability, and customization is redefining how manufacturers approach assembly techniques. Companies that leverage these trends not only improve their operational efficiencies but also enhance product quality, meeting the demands of modern consumers who seek reliability and performance.

With these developments in mind, it is essential for organizations to prepare for the future of wire harness assembly. By understanding and implementing the emerging trends, businesses can position themselves as leaders in the industry, ensuring they remain competitive and responsive to the needs of their clients while navigating the challenges ahead.

Table of Contents

[Hide]

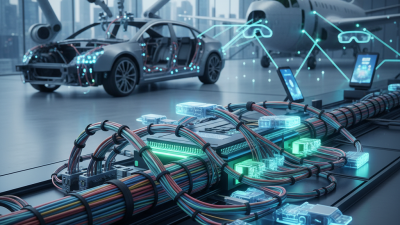

Emerging Technologies Shaping Wire Harness Assembly in 2025

As we approach 2025, several emerging technologies are poised to redefine the wire harness assembly landscape. One of the most significant trends is the increasing adoption of automation and robotics. According to a report from MarketsandMarkets, the global industrial robotics market is expected to reach $75 billion by 2025, with wire harness assembly applications being a key driver of this growth. Automated assembly processes not only enhance precision but also drastically reduce assembly time, yielding better productivity and cost efficiency.

Additionally, the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and Artificial Intelligence (AI), is transforming how wire harnesses are designed and produced. A study from McKinsey indicates that AI in manufacturing could boost productivity by 20% to 25% by 2025. By employing data analytics and predictive maintenance, manufacturers can optimize production processes, anticipate equipment failures, and significantly reduce downtime. The convergence of these technologies promises to create smarter manufacturing environments that can adapt in real-time to varying production demands, ultimately elevating product quality and operational efficiency within the wire harness sector.

Lastly, eco-friendly and sustainable materials are becoming increasingly important in wire harness assembly. A report by Research and Markets highlights that the global green technology and sustainability market will be valued at $36 billion by 2025. The shift towards biodegradable and recyclable materials will not only address environmental concerns but also meet the growing demand for sustainable practices in manufacturing. As the industry adapts to meet regulatory requirements and consumer expectations, the use of innovative materials will play a critical role in shaping the future of wire harness assembly.

Top Trends in Wire Harness Assembly for 2025

Sustainability Practices Impacting Wire Harness Manufacturing

As the demand for wire harness assemblies continues to grow, sustainability practices are increasingly shaping the landscape of manufacturing in 2025. Manufacturers are now prioritizing eco-friendly materials and processes to minimize environmental impacts. This shift involves the adoption of recyclable insulation materials and the integration of energy-efficient manufacturing technologies, which not only reduce waste but also lower emissions. By embracing these practices, companies can significantly decrease their carbon footprint while meeting the rising consumer demand for sustainable products.

In addition to material innovation, manufacturers are re-evaluating their supply chains to embrace sustainability. This includes sourcing components from suppliers who adhere to ethical and environmentally friendly practices. Many companies are also investing in circular economy models, where products are designed for longevity and eventual recycling, thereby promoting resource efficiency. As regulations related to environmental practices tighten globally, wire harness manufacturers who proactively adopt these changes will likely gain a competitive advantage in the market while contributing to a greener future.

Automation and Robotics Trends in Wire Harness Production

The wire harness assembly industry is poised for significant transformation in 2025, largely driven by advancements in automation and robotics. According to a recent market report, the adoption of automated solutions in wire harness production is expected to increase by 22% over the next two years, enabling manufacturers to enhance efficiency and reduce labor costs. The integration of robotics not only streamlines production processes but also improves precision and consistency in the assembly of wire harnesses, which are crucial components in automotive, aerospace, and electronic applications.

In particular, the implementation of collaborative robots (cobots) in wire harness assembly is gaining traction. Unlike traditional industrial robots that require safety enclosures, cobots can work alongside human operators, providing flexibility and adaptability in production lines. This shift allows for the seamless integration of automated systems that can handle repetitive tasks, freeing human workers to focus on more complex and value-added activities. A study indicates that companies utilizing cobots see a productivity increase of approximately 30%, which is critical for meeting rising demand while maintaining quality standards in wire harness assembly. As automation technologies continue to evolve, keeping abreast of these trends will be essential for stakeholders in the wire harness manufacturing sector.

Top Trends in Wire Harness Assembly for 2025: What You Need to Know

| Trend | Description | Impact on Production | Technology Involved |

|---|---|---|---|

| Increased Automation | Adoption of automated assembly lines to enhance efficiency | Higher throughput and reduced labor costs | Robotic arms, AI-based programming |

| Smart Manufacturing | Integration of IoT for real-time monitoring and feedback | Improved quality control and reduced downtime | IoT sensors, data analytics |

| Sustainability Initiatives | Focus on eco-friendly materials and processes | Enhanced brand image and regulatory compliance | Recyclable materials, energy-efficient machinery |

| Advanced Design Techniques | Utilization of 3D CAD modeling for complex assemblies | Reduced assembly time and improved accuracy | 3D CAD software, simulation tools |

| Cybersecurity Measures | Implementation of security protocols within production networks | Protection against data breaches and operational disruptions | Firewalls, encryption technologies |

Customization and Flexibility in Wire Harness Design

In the rapidly evolving landscape of wire harness assembly, customization and flexibility have emerged as critical trends for 2025. As industries diversify and demand for specialized solutions grows, manufacturers are increasingly shifting their focus towards tailor-made wire harness designs. This shift empowers engineers and designers to create harnesses that not only meet specific application requirements but also enhance efficiency and performance across various sectors, from automotive to aerospace.

The move towards flexible design processes allows for quicker iterations and adaptations, enabling companies to respond swiftly to market changes or customer preferences. Modular design principles can streamline production, facilitating easier updates to wiring configurations without the need for complete redesigns. This agility not only cut lead times but also reduces waste by allowing manufacturers to adapt existing components rather than starting from scratch. Overall, the emphasis on customization and flexibility in wire harness assembly is transforming how engineers tackle design challenges, ultimately leading to more innovative solutions and improved product offerings.

Future Challenges and Solutions for Wire Harness Assembly Industry

As the wired harness assembly industry gears up for 2025, several challenges are evolving alongside emerging trends. One significant challenge is the increasing complexity of wiring systems, driven by the rise of electric vehicles and smart technology integration. According to a report from MarketsandMarkets, the global automotive wiring harness market is projected to reach $60 billion by 2025, emphasizing the need for assembly processes that can handle sophisticated configurations while maintaining quality and efficiency.

To navigate these complexities, companies in the wire harness sector must embrace advanced automation technologies, such as robotics and AI-driven assembly lines. Implementing these solutions can enhance flexibility and reduce labor costs, addressing the skilled labor shortages prevalent in the industry. A recent study from Deloitte highlights that 70% of manufacturers believe that automation will play a critical role in overcoming labor challenges in the coming years.

Tip: Invest in workforce training programs to upskill employees on new technologies and processes. This investment not only improves efficiency but also fosters a culture of continuous improvement and innovation.

Moreover, the emphasis on sustainability is reshaping the industry’s landscape. As regulatory pressures increase and customers demand greener solutions, utilizing eco-friendly materials in wire harness manufacturing can set businesses apart. According to a report by Grand View Research, the market for sustainable materials is expected to expand significantly, presenting an opportunity for companies to innovate while aligning with environmental goals.

Tip: Consider collaborating with suppliers who specialize in sustainable materials to enhance your product offerings and appeal to eco-conscious consumers.

Related Posts

-

Top 2025 Wire Harness Trends: Innovations and Essential Applications

-

How to Choose the Right Wire Harness for Your Project in 2025

-

Top 10 Essential Tips for Efficient Wire Harness Assembly Processes

-

What is PCB and Assembly Process Explained for Beginners

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

Why Printed PCBs Are Essential for Modern Electronics Innovation