Exploring Real Life Applications of the Best Automatic Power Factor Controller in Various Industries

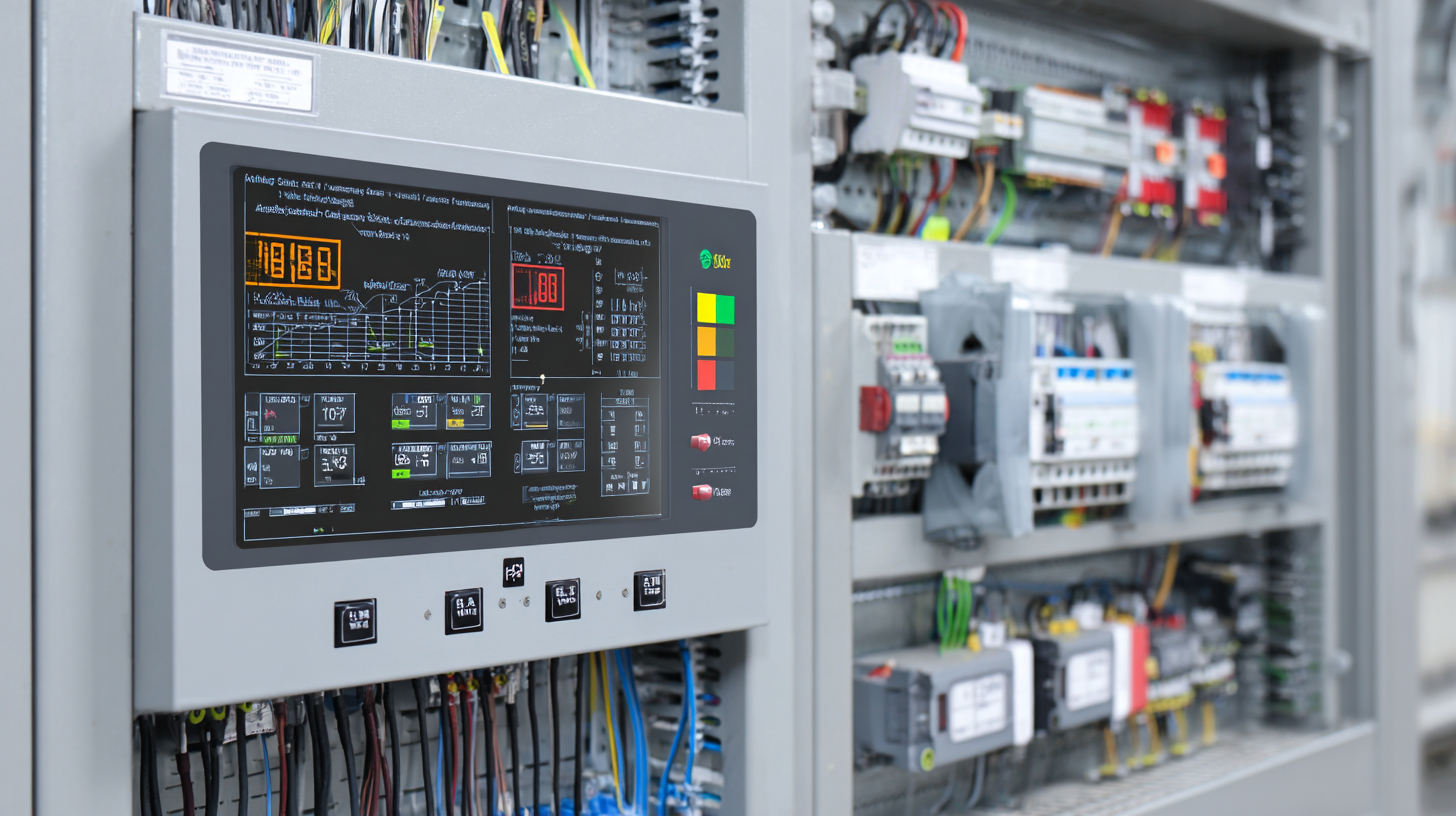

In today's fast-paced industrial landscape, the efficiency of electrical systems has become paramount for maximizing productivity and reducing operational costs. One of the key players in achieving this efficiency is the Automatic Power Factor Controller (APFC). This innovative device not only optimizes power usage but also enhances the power quality by correcting the power factor in real-time. As various industries strive to improve their energy management systems, understanding the technical specifications and capabilities of the best APFCs is crucial. In this blog, we will explore the real-life applications of Automatic Power Factor Controllers across diverse sectors, shedding light on how they contribute to energy savings and operational excellence. Additionally, we will provide a comprehensive tutorial, ensuring readers are equipped with the knowledge to leverage these advanced systems effectively.

Real-Time Monitoring and Control: Enhancing Power Factor in Manufacturing Plants

The importance of power factor in manufacturing plants cannot be understated. A high power factor indicates efficient utilization of electrical power, which is crucial in maintaining operational costs. Real-time monitoring and control, facilitated by the latest automatic power factor controllers (APFC), enable manufacturers to enhance their energy efficiency. According to a report by the International Energy Agency (IEA), improving power factor by just 0.1 can lead to a reduction in energy costs by approximately 2-5%. This cost-saving potential underscores the necessity for industries to adopt sophisticated power factor correction technologies.

Incorporating APFC systems allows for immediate adjustments in response to fluctuating loads, ensuring that power factor remains optimized. For instance, the Global Energy Monitoring Group reported that manufacturers using automatic controllers have consistently achieved power factor levels above 0.95, significantly surpassing the average industrial level of 0.85. This enhancement translates into lower penalties from utility companies and increased operational efficiency, making real-time control not just a technical advancement but a vital economic strategy.

**Tips:** Regularly audit your factory's power factor and energy consumption. Use advanced analytics to anticipate load changes and adjust your systems proactively. Implementing an automated monitoring solution can streamline these efforts, helping you stay ahead in energy management and reduce unnecessary costs.

Exploring Real Life Applications of the Best Automatic Power Factor Controller in Various Industries

| Industry | Application | Power Factor Improvement (%) | Energy Savings (%) | Real-Time Monitoring |

|---|---|---|---|---|

| Manufacturing | Injection Molding Machines | 15% | 10% | Yes |

| Food Processing | Mixers and Blenders | 12% | 8% | Yes |

| Textiles | Spinning and Weaving Machines | 20% | 12% | Yes |

| Automotive | Assembly Line Robotics | 18% | 11% | Yes |

| Pharmaceuticals | Packaging Machines | 16% | 9% | Yes |

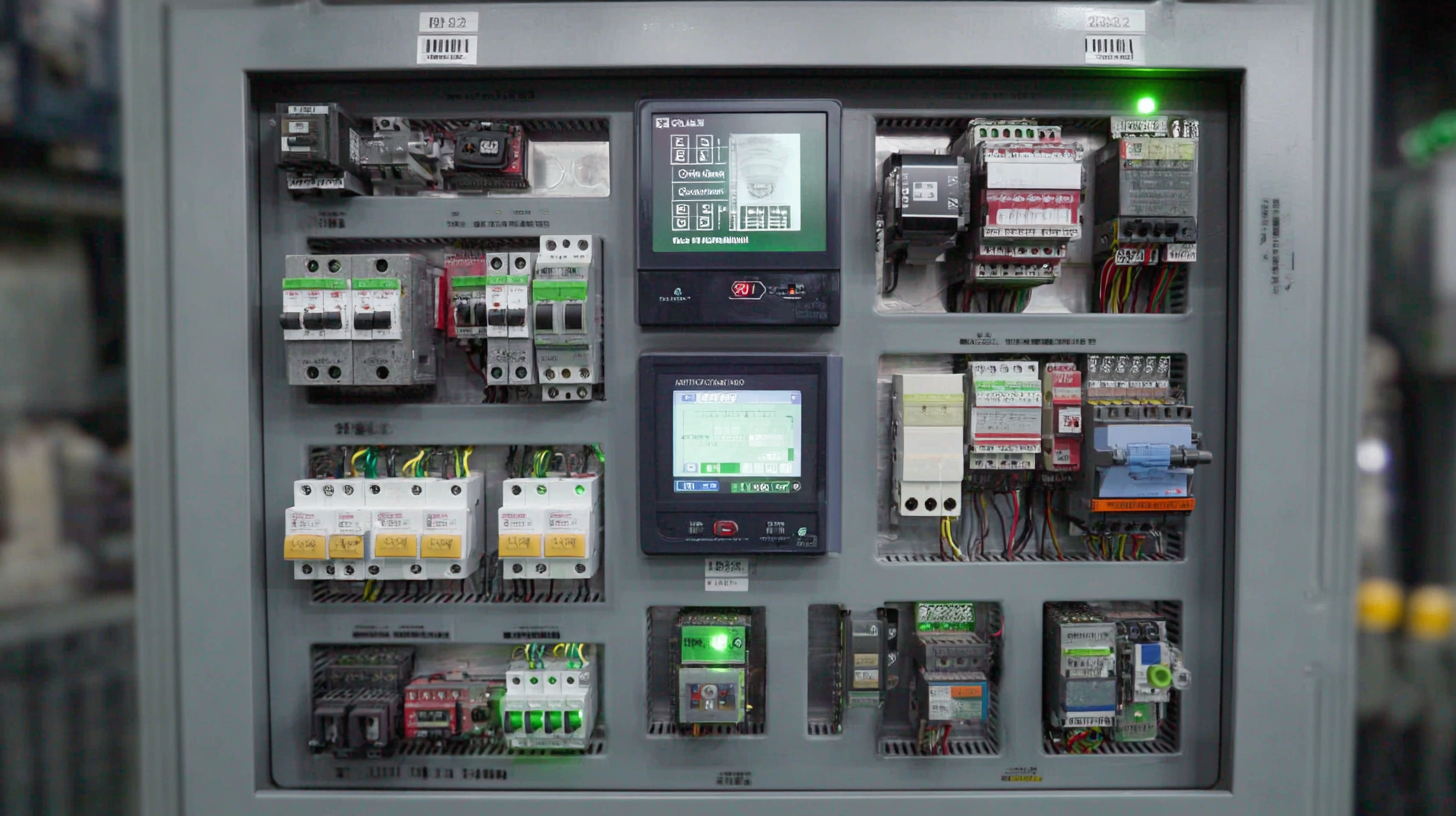

Impact of Automatic Power Factor Controllers on Energy Savings in Commercial Buildings

Automatic Power Factor Controllers (APFCs) play a crucial role in enhancing energy efficiency in commercial buildings. By managing the reactive power in electrical systems, these devices help to improve the overall power factor, which is a measure of how effectively electrical energy is being converted into useful work. A higher power factor leads to reduced energy loss and can significantly lower electricity costs. In many commercial settings, where large motors and transformers are utilized, achieving an optimal power factor is essential. The integration of APFCs allows businesses to stabilize their voltage levels and reduces excess demand charges from utilities.

The impact on energy savings is profound. By ensuring that electrical systems operate close to their maximum efficiency, APFCs not only lower energy costs but also prolong the lifespan of equipment. When reactive power is effectively managed, the risk of overheating and equipment failure diminishes, leading to reduced maintenance costs and downtime. Moreover, buildings equipped with APFCs often benefit from incentives provided by utility companies, further enhancing their financial savings. As industries continue to seek sustainable practices, the adoption of Automatic Power Factor Controllers presents a compelling solution for energy efficiency in commercial buildings.

Impact of Automatic Power Factor Controllers on Energy Savings in Commercial Buildings

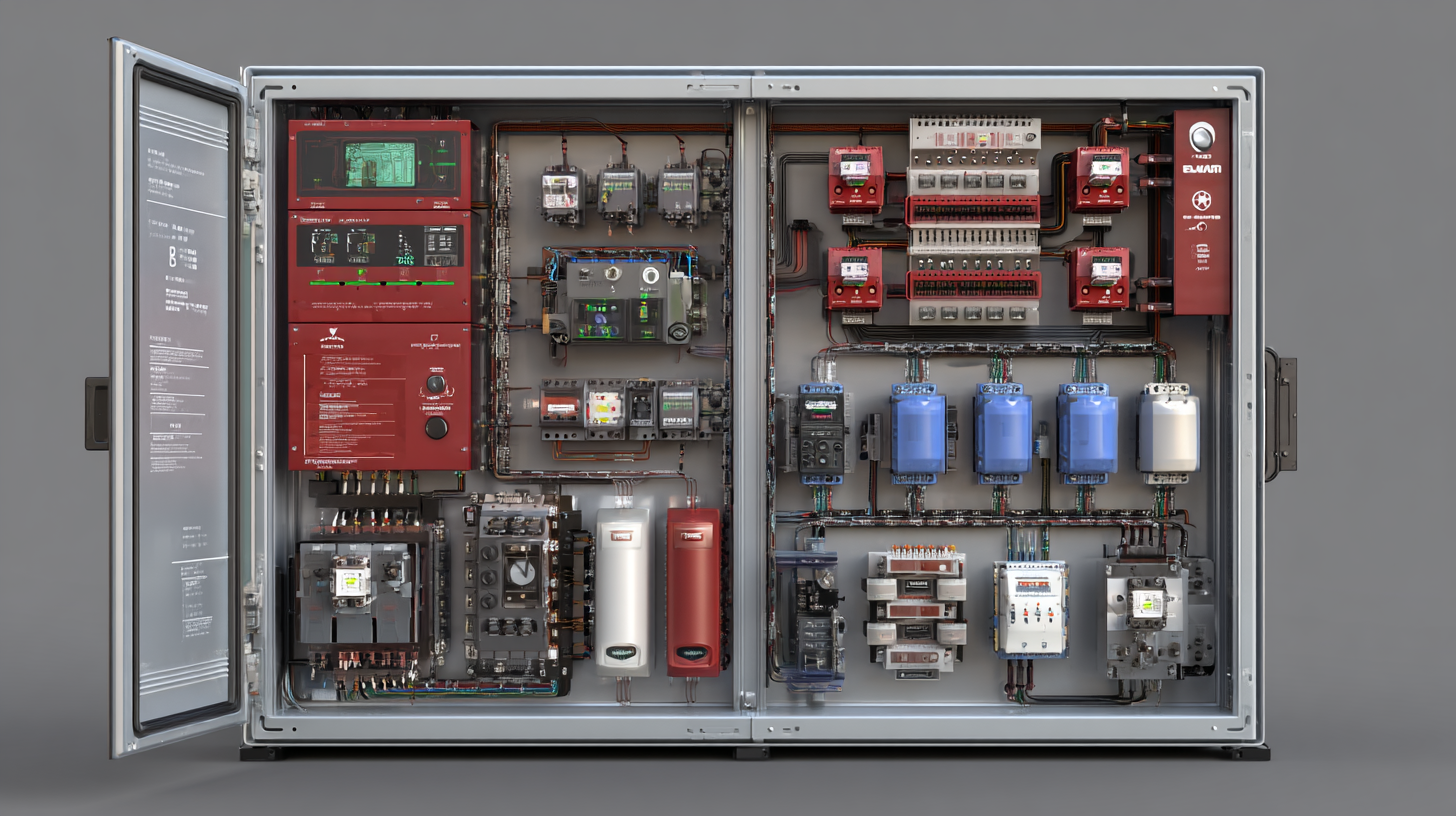

Case Studies: Successful Implementation of Power Factor Controllers in the Automotive Industry

In the automotive industry, the implementation of Automatic Power Factor Controllers (APFC) has ushered in a new era of energy efficiency, significantly reducing operational costs. According to a report by the International Energy Agency, automotive manufacturers can save up to 30% on electricity bills by optimizing their power factor through the installation of APFC systems. This technology not only stabilizes the system voltage but also minimizes the risk of penalties associated with poor power factor ratings.

Several case studies highlight successful APFC implementations within the automotive sector. For instance, a leading automotive manufacturer in Germany integrated APFC units into their production lines, resulting in a power factor improvement from 0.75 to a commendable 0.95. This enhancement allowed them to avoid estimated utility fines of €50,000 per year, illustrating the potential financial benefits of such systems. Furthermore, the enhanced power factor contributed to increased machinery efficiency, prolonging equipment life and resulting in fewer operational downtimes. Such strides showcase the transformative impact of APFC technology in the automotive domain, further emphasizing its necessity for industries looking to achieve optimal energy performance.

Achieving Regulatory Compliance: The Role of Automatic Controllers in Reducing Harmonics

Automatic Power Factor Controllers (APFCs) play a crucial role in achieving regulatory compliance by effectively reducing harmonics in industrial settings.

Harmonics can distort the electrical supply, leading to inefficiencies and potential penalties from utility providers. By employing APFCs, industries can not only optimize energy consumption but also ensure that their operations meet the stringent standards set by regulatory bodies.

Tip: Regularly assess your power factor and harmonic distortion levels. Implementing APFCs can significantly improve these metrics, helping avoid costly fines and enhancing energy efficiency.

The adoption of advanced automatic controllers enables industries to monitor and manage power quality more effectively. These controllers adapt to changing load conditions in real-time, mitigating harmonic distortion and stabilizing power factor levels. This dynamic adjustment is vital for maintaining compliance with industry regulations, ensuring smoother operations, and extending the lifespan of electrical equipment.

Tip: Consider investing in smart APFCs that provide detailed analytics and real-time monitoring capabilities. This data can guide maintenance efforts and help adjust operational practices to further reduce harmonics.

Future Trends: Integrating Smart Technology in Power Factor Control for Sustainable Industries

The integration of smart technology in power factor control is poised to transform industries towards greater sustainability. As businesses increasingly adopt automatic power factor controllers (APFCs), the trend is shifting towards smart systems that can dynamically adjust to varying energy demands and improve energy efficiency. These intelligent controllers, equipped with advanced algorithms and real-time monitoring capabilities, not only optimize power consumption but also help reduce carbon footprints, aligning with global sustainability goals.

Looking ahead, the future of power factor control will likely see a greater emphasis on connectivity and data analytics. The rise of the Internet of Things (IoT) means that APFCs will no longer function in isolation; instead, they will be part of a broader ecosystem of smart devices that communicate and collaborate in real time. This interconnectedness will enhance predictive maintenance, reduce operational disruptions, and promote energy management strategies that are both efficient and environmentally friendly, enabling various industries to thrive in a sustainable manner.