Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top PCB Assembly Trends to Watch in 2025 for Electronics Manufacturers

The landscape of electronics manufacturing is rapidly evolving, and one of the most significant elements driving this change is PCB assembly. According to industry reports, the global PCB market is expected to reach $77 billion by 2025, with a substantial portion attributed to advancements in PCB assembly technology. As electronic devices become increasingly complex and demand for high-performance components surges, manufacturers must stay ahead of emerging trends that could impact production processes and product design.

In recent years, key trends in PCB assembly have been shaped by the rise of automation and artificial intelligence, as these technologies are increasingly integrated into manufacturing processes. A report from TechNavio predicts that the PCB assembly automation market will witness a compound annual growth rate (CAGR) of over 8% from 2021 to 2025. This shift not only enhances production efficiency but also significantly reduces human error, a critical factor in maintaining quality in the competitive electronics market.

Moreover, sustainability has become a pivotal concern for manufacturers, with a growing emphasis on eco-friendly materials and processes in PCB assembly. As per a global sustainability report, over 70% of consumers are willing to pay a premium for sustainably manufactured products, prompting manufacturers to adopt greener practices. By keeping a close watch on these trends, electronics manufacturers can better position themselves to thrive in the dynamic landscape of PCB assembly by 2025.

Table of Contents

[Hide]

Emerging Technologies Impacting PCB Assembly in 2025

As electronics manufacturers look toward 2025, several emerging technologies are poised to significantly impact PCB assembly processes. One notable trend is the increased adoption of automation and robotics in PCB assembly lines. Reports suggest that the robotics market in electronics manufacturing could grow at a CAGR of over 15% from 2023 to 2028, driven by the need for efficiency and precision in assembly processes. Automated systems not only enhance production speed but also reduce human errors, thereby ensuring higher quality standards vital for today’s competitive landscape.

Another transformative technology shaping PCB assembly is the integration of artificial intelligence (AI) and machine learning (ML) for predictive maintenance and quality assurance. According to a recent industry analysis, the use of AI in manufacturing is expected to reach $190 billion by 2025, leading to smarter production systems that can anticipate equipment failures before they occur. This capability not only minimizes downtime but also optimizes the supply chain, allowing manufacturers to respond more agilely to market demands.

Furthermore, the move towards smaller and more complex electronic devices will necessitate advanced materials and processes. The global flexible PCB market is projected to reach $25 billion by 2025, as manufacturers increasingly incorporate flex circuits to meet the need for compact designs in consumer electronics and wearables. These trends underscore the pivotal role of innovative technologies in transforming PCB assembly practices, setting a new standard for efficiency, reliability, and design capability in the electronics manufacturing industry.

Top PCB Assembly Trends to Watch in 2025 for Electronics Manufacturers

| Trend | Description | Impact Level | Adoption Rate (%) |

|---|---|---|---|

| Automation in PCB Assembly | Increasing reliance on automated systems to improve efficiency and reduce costs. | High | 70 |

| AI and Machine Learning | Leveraging AI for predictive maintenance and quality control in PCB manufacturing. | Medium | 50 |

| Sustainability Practices | Incorporating eco-friendly materials and processes in PCB production. | High | 65 |

| 5G and IoT Integration | Designing PCBs that accommodate 5G technologies and Internet of Things applications. | High | 80 |

| Flexible and Printed Electronics | Development of PCBs that are flexible and printed, catering to new applications. | Medium | 45 |

Sustainability Practices in PCB Manufacturing for Electronics

As the electronics industry continues to evolve, sustainability practices in PCB manufacturing are becoming increasingly crucial. Electronics manufacturers are now focusing on reducing their environmental footprint by adopting eco-friendly materials and processes. This includes the use of lead-free solder and halogen-free laminates, which not only comply with international regulations but also improve recyclability. Manufacturers are also exploring biocompatible materials derived from renewable resources, emphasizing a commitment to sustainability throughout the product lifecycle.

In addition to materials, energy efficiency during production is gaining prominence. Many manufacturers are investing in advanced technologies that optimize energy consumption and minimize waste. Implementing lean manufacturing principles helps streamline processes, reduce scrap rates, and enhance overall efficiency. Furthermore, the recycling of waste materials generated during PCB production is becoming standard practice, allowing companies to reclaim valuable resources. As manufacturers transition to circular economy models, the focus on sustainability will not only benefit the environment but also enhance their competitive edge in a market increasingly driven by consumer demand for eco-friendly products.

The Role of Automation and AI in PCB Assembly Processes

As we look towards 2025, the integration of automation and artificial intelligence (AI) into PCB assembly processes is transforming the landscape for electronics manufacturers. Automation not only enhances productivity by enabling faster production cycles but also improves precision and reduces human error. AI plays a crucial role in optimizing assembly line operations, utilizing machine learning algorithms to predict equipment failures and streamline workflows, thus increasing the efficiency of the entire production process.

Tips for manufacturers to leverage automation and AI include investing in smart machinery that supports real-time data analytics. This will allow teams to monitor production metrics continuously and make informed adjustments on the fly. Additionally, embracing collaborative robots, or cobots, can enhance assembly operations by working alongside human operators, facilitating complex tasks and enabling higher throughput.

Moreover, incorporating AI-driven quality control systems can significantly reduce defects in PCB assembly. These systems can analyze visual data from production lines to identify anomalies and ensure that each component meets stringent quality standards. By taking advantage of these technologies, manufacturers can not only enhance their operational capabilities but also position themselves competitively in the increasingly complex electronics market.

Trends in Miniaturization for Next-Generation PCB Designs

As the electronics manufacturing industry evolves, miniaturization remains a paramount trend shaping the design of next-generation printed circuit boards (PCBs). By 2025, the global PCB market is projected to reach approximately $80 billion, driven largely by the increasing demand for compact and efficient electronics. Reports indicate that the miniaturization trend is being fueled by advances in technology, enabling manufacturers to produce smaller yet more powerful components. This shift is particularly evident in sectors such as consumer electronics, medical devices, and automotive applications, where space constraints and performance enhancements are critical.

Recent studies indicate that the push for miniaturization has led to the development of high-density interconnect (HDI) PCBs, which allow for a greater number of connections and features in a reduced footprint. By leveraging technologies like through-vias and microvias, manufacturers can increase the functionality of PCBs while adhering to smaller size specifications. A report from IPC shows that HDI technology is expected to grow at a compound annual growth rate (CAGR) of 15% over the next few years, highlighting its significance in the realm of miniaturized electronics. As manufacturers adopt these innovative approaches, the industry will see a renaissance in design possibilities, pushing the boundaries of what is achievable in electronic devices.

Miniaturization Trends in PCB Design by 2025

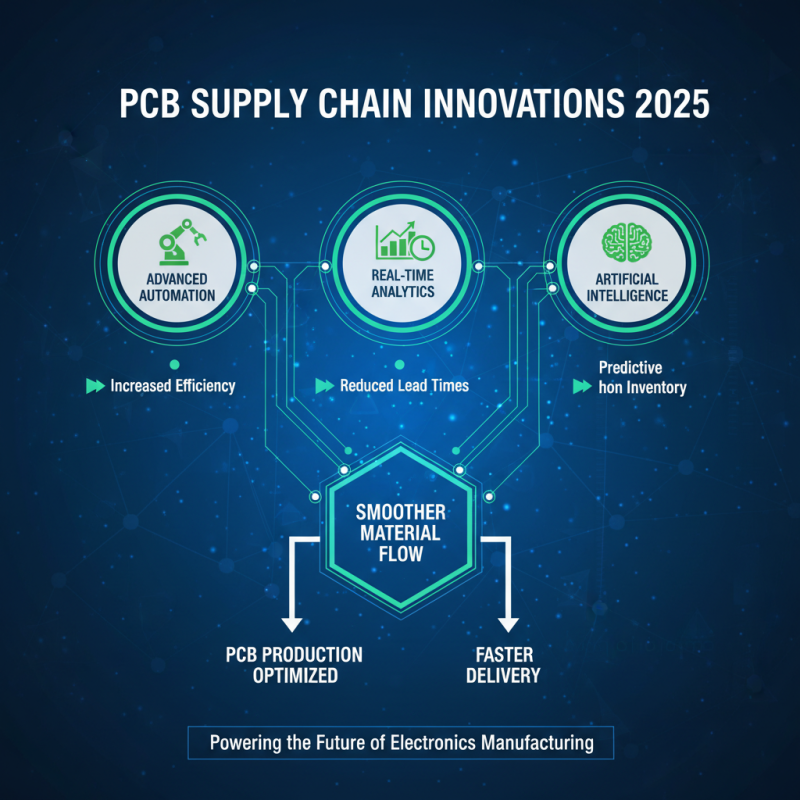

Supply Chain Innovations Affecting PCB Production and Delivery

The evolving landscape of electronics manufacturing in 2025 presents new supply chain innovations that significantly impact PCB production and delivery. As manufacturers strive to enhance efficiency and reduce lead times, technologies such as advanced automation, real-time analytics, and artificial intelligence are being integrated into the supply chain. These tools facilitate better inventory management and help predict potential disruptions, ensuring a smoother flow of materials and components necessary for PCB assembly.

Tips: To stay ahead in this rapidly changing environment, electronics manufacturers should consider investing in supply chain management software that utilizes predictive analytics. This can help identify trends and anticipate demands, ultimately leading to improved operational efficiency. Additionally, fostering strong relationships with suppliers can provide more flexibility during times of supply chain volatility.

Furthermore, sustainability is becoming a focal point in supply chain innovation. Manufacturers are increasingly prioritizing eco-friendly materials and processes in PCB production, aligning with growing consumer and regulatory demands for greener options. By adopting sustainable practices, companies not only reduce their environmental impact but also enhance their brand reputation in a competitive market.

Tips: When exploring sustainable materials, manufacturers should conduct thorough research to understand the long-term benefits and potential challenges. Collaborating with supply chain partners who share a commitment to sustainability can drive collective efforts towards greener PCB solutions.

Related Posts

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

Understanding the Future of Electronic Board Assembly in Modern Technology

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

10 Essential Tips for Designing High-Quality Printed PCB Boards Efficiently