Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

2026 How to Choose the Best Stainless Steel Woven Wire Mesh?

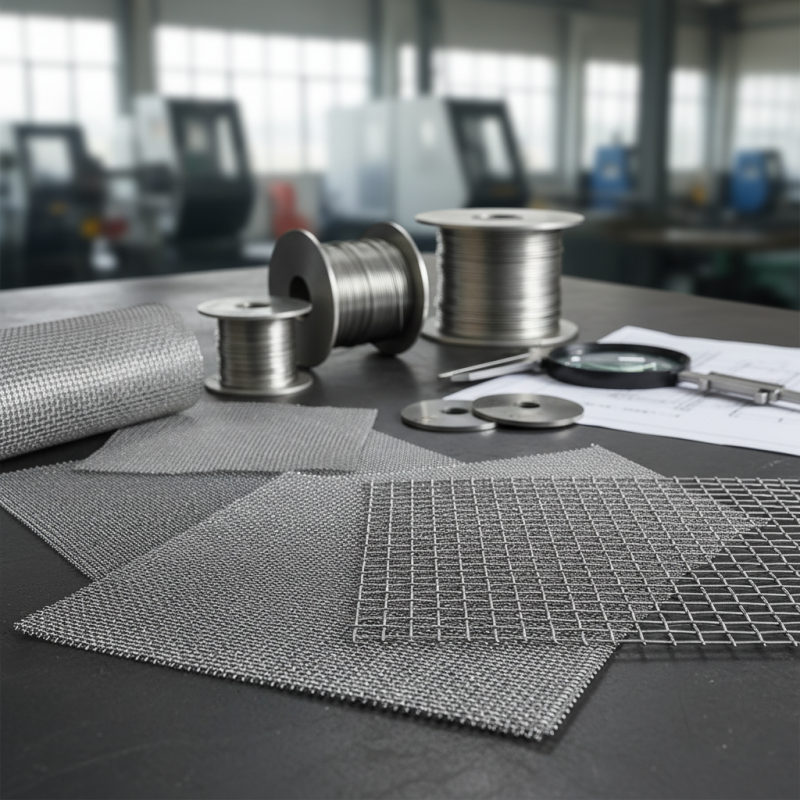

When it comes to selecting the right stainless steel woven wire mesh, various factors come into play. The choice is crucial for its intended application. This type of mesh is widely used in industries ranging from construction to food processing. Understanding the specific properties of stainless steel woven wire mesh is essential for making an informed decision.

Different wire diameters and mesh openings offer unique benefits. For example, a tighter weave may be necessary for filtering. Alternatively, a looser mesh could provide better ventilation in some settings. Customers often overlook these nuances, leading to unsatisfactory results.

Quality and grade of stainless steel must be considered as well. Not all stainless steel is created equal, and variations in corrosion resistance can impact performance. Additionally, some might find the cost of high-quality products challenging. It may require reevaluation of budget constraints. Understanding your specific needs and potential trade-offs is key to choosing the best stainless steel woven wire mesh for your project.

Table of Contents [Hide]

Factors to Consider When Selecting Stainless Steel Woven Wire Mesh

Choosing the right stainless steel woven wire mesh can be challenging. It's important to consider several factors for your specific application. One key aspect is the wire diameter. Thicker wires offer better strength. However, they may reduce flexibility. According to recent industry reports, a 1 mm wire diameter provides optimal balance for most uses.

Mesh opening is another crucial factor. Smaller openings filter finer particles but can restrict airflow. Conversely, larger openings enhance air circulation but may not retain smaller particles. Data indicates that a 0.5 mm opening is ideal for air filtration. Yet, this may not suit every environment.

Finally, tolerance levels must be evaluated. A mesh with high tolerances ensures consistent performance. Some users overlook this detail, resulting in poor functionality. Quality control metrics suggest that variations in mesh size can reach up to 10%. This discrepancy could lead to inefficiencies. Understanding these variables helps in selecting the best stainless steel woven wire mesh for your needs.

Understanding the Different Types of Stainless Steel Wire Mesh

When selecting the right stainless steel wire mesh, understanding its types is crucial. Stainless steel woven wire mesh comes in various styles and specifications. The choice often depends on intended use and environment. For industrial applications, a tighter weave is usually preferred. This ensures strength and durability. In contrast, for decorative purposes, a looser or more intricate weave could be suitable.

Stainless steel wire meshes are classified mainly by weave patterns. Plain weave is standard and widely used. It consists of two wires interlacing in a simple grid. It provides strength but may lack flexibility. Twill weave offers a more complex interlace. It is stronger than plain weave and more adaptable. But it may not be ideal for all projects due to its higher cost.

Another type is welded mesh, produced by fusing wire intersections. This creates a stable and robust frame, ideal for construction. It can also be heavy, which some projects may not require. Reflecting on these choices can be tough. One might ponder, is strength more important than flexibility? Decisions often come down to the project’s specific needs. Understanding these nuances plays a vital role in making the right choice.

2026 How to Choose the Best Stainless Steel Woven Wire Mesh? - Understanding the Different Types of Stainless Steel Wire Mesh

| Type of Stainless Steel Wire Mesh | Mesh Opening (mm) | Wire Diameter (mm) | Material Grade | Common Applications |

|---|---|---|---|---|

| Plain Woven Mesh | 0.5 - 100 | 0.1 - 10 | 304, 316 | Filtration, sieving |

| Dutch Weave Mesh | 0.2 - 5 | 0.2 - 1.0 | 316L | Oil and gas filtration |

| Twill Weave Mesh | 0.1 - 50 | 0.5 - 8 | 304, 321 | Food processing, chemical processing |

| Square Mesh | 1 - 100 | 0.3 - 6 | 430, 304 | Construction, filters |

| Hexagonal Wire Mesh | 15 - 50 | 0.5 - 3 | 304 | Poultry, gardens |

Evaluating Mesh Openings and Wire Diameter for Your Needs

When choosing stainless steel woven wire mesh, evaluating mesh openings and wire diameter is crucial. The opening size determines what can pass through the mesh. Larger openings allow bigger items, while smaller openings provide more filtration. It’s important to assess your specific application. For instance, if you're using the mesh for drainage, a larger opening may be suitable. Conversely, for filtration or screening purposes, smaller openings are ideal.

Wire diameter impacts the strength and durability of the mesh. Thicker wires create a more robust mesh but reduce flexibility. On the other hand, thinner wires offer better adaptability but may not withstand heavy loads. Carefully considering the environment is essential. High-stress situations demand thicker wires, while lighter applications may benefit from thinner options.

It's easy to overlook how these factors can affect the end product. Many users focus solely on one aspect, potentially compromising performance. Think about the specific requirements of your project. The balance between mesh opening and wire diameter is vital. Prioritize your unique needs to make an informed decision.

Application Scenarios for Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh finds its way into various application scenarios. Its versatility makes it a popular choice in many industries. This mesh is commonly used in filtering and separation processes. The durable nature of stainless steel ensures a long-lasting performance, even in harsh environments.

Construction sites utilize stainless steel woven wire mesh for safety barriers. It helps keep debris contained and protects workers. In agriculture, it serves as sturdy fencing to keep livestock secure. The mesh also aids in soil erosion control, preventing land degradation. Its strength offers peace of mind for farmers.

In industrial settings, the mesh is essential in equipment protection. It prevents particles from contaminating products during manufacturing. However, choosing the right type can be tricky. Different wire diameters and weave patterns present varied strengths and weaknesses. It's important to reflect on specific needs before making a decision. The right mesh can enhance efficiency, but the wrong choice may lead to issues.

Maintenance and Durability of Stainless Steel Wire Mesh Products

Stainless steel woven wire mesh is known for its impressive durability and maintenance. Regular cleaning is essential to prevent corrosion. Depending on the environment, even high-quality stainless steel can tarnish. Use mild detergents and soft brushes for maintenance. Harsh chemicals might harm the surface over time.

Humidity and exposure to harsh elements can affect longevity. Consider protecting your mesh with a clear coat. This layer can extend its life by shielding it from pollutants and moisture. Inspecting the mesh regularly helps identify any early signs of wear. Small issues can escalate quickly. Addressing them immediately is wise.

Ensure proper installation to avoid stress points. A poorly installed mesh may suffer faster degradation. Knowing your mesh's specific grade will guide you in using it effectively. With attention to detail and proper care, stainless steel woven wire mesh can serve well for years. However, neglect can lead to regret. Stay proactive for the best results.