Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Harness Assembly for Efficient Production and Workflow Optimization

In today's fast-paced manufacturing landscape, the ability to streamline production processes and enhance workflow efficiency is paramount. One of the most effective strategies to achieve these goals is to harness assembly techniques, which focus on optimizing collaborative efforts in production environments. By tapping into the potential of assembly, organizations can create a balanced workflow that minimizes bottlenecks, reduces lead times, and improves overall output quality.

Harnessing assembly not only involves the physical arrangement of workstations and the sequential flow of tasks but also emphasizes the importance of skilled labor and innovative practices. As businesses strive to fulfill increasing consumer demands, understanding how to leverage assembly effectively becomes crucial. This informed approach enables teams to respond agilely to changes while maintaining high standards of productivity.

In this article, we will explore various methods for harnessing assembly in production settings. We will discuss key concepts, best practices, and real-world applications that demonstrate how a well-implemented assembly strategy can lead to significant improvements in efficiency and workflow optimization. Whether for large-scale manufacturing or smaller, specialized operations, the principles of harnessing assembly can propel businesses towards sustainable success.

Table of Contents

[Hide]

Understanding the Role of Assembly in Production Processes

In today's competitive manufacturing landscape, understanding the role of assembly in production processes is crucial for enhancing efficiency and effectiveness. Assembly acts as the backbone of production, where individual components come together to form a finished product. This phase significantly impacts the overall workflow, as it involves careful coordination of resources, labor, and time. By optimizing assembly processes, companies can reduce lead times and minimize errors, paving the way for higher quality outputs.

Moreover, effective assembly processes contribute to workflow optimization by streamlining operations and ensuring that each step in the production line is executed flawlessly. Implementing techniques such as Just-In-Time (JIT) manufacturing helps in synchronizing the arrival of materials with production schedules, reducing inventory costs and waste. Additionally, the use of modular assembly techniques can enhance flexibility and adaptability, allowing businesses to quickly respond to changes in demand without disrupting the overall production flow. In this way, a well-structured assembly process is vital for achieving operational excellence and maintaining a competitive edge in the market.

Production Efficiency Through Assembly Workflow Optimization

Key Principles of Efficient Workflow Optimization

Efficient workflow optimization is critical in any production environment aiming to improve performance and reduce costs. One of the key principles is the implementation of standardized processes. By defining clear workflows and ensuring that all team members are trained to follow these established protocols, organizations can minimize errors and enhance productivity. Standardization allows for easier tracking of performance metrics, which can be analyzed to identify bottlenecks and areas for improvement.

Another fundamental principle involves the integration of visual management tools within the workspace. These tools, such as boards displaying real-time progress, can help teams stay aligned and informed about ongoing tasks. Visual cues facilitate better communication and ensure that everyone is aware of their responsibilities, thereby streamlining the workflow. Furthermore, involving employees in the optimization process fosters a culture of continuous improvement, where team members contribute insights from their own experiences to refine processes further. By creating an environment that values input and innovation, organizations can unlock greater efficiencies in production.

Strategies for Designing Effective Assembly Lines

Designing effective assembly lines is crucial for enhancing productivity and minimizing waste in production processes. One key strategy involves analyzing the workflow to identify bottlenecks. By mapping out each step of the assembly line, you can spot inefficiencies and areas for improvement. Streamlining these processes not only accelerates production but also improves worker satisfaction, as tasks become more manageable and organized.

Tips: Consider implementing a modular design approach, where assembly stations are adaptable to different products or models. This flexibility allows teams to quickly adjust to changes in demand without overhauling the entire production line. Additionally, prioritizing ergonomic designs at workstations can reduce fatigue, leading to increased efficiency and lower error rates.

Another vital strategy is to incorporate real-time data analytics into the assembly process. By using metrics to monitor production performance continuously, teams can make informed decisions on staffing, equipment usage, and resource allocation. This data-driven approach fosters a proactive environment where adjustments can be made swiftly to maintain optimal productivity.

Tips: Regularly engage with employees to gather insights on their experiences and suggestions for improvement. Workers on the assembly line often have valuable perspectives on the challenges they face, and involving them in refinement efforts can lead to innovative solutions and a more cohesive work environment.

How to Harness Assembly for Efficient Production and Workflow Optimization - Strategies for Designing Effective Assembly Lines

| Assembly Line Stage | Task Description | Average Time per Unit (minutes) | Bottleneck Indicator | Optimization Strategy |

|---|---|---|---|---|

| Receiving | Quality check of incoming materials | 5 | Low | Implement stricter supplier quality controls |

| Assembly | Component assembly | 10 | Medium | Introduce modular assembly tools |

| Testing | Functional testing of units | 7 | High | Automate testing procedures |

| Packaging | Final packaging of completed products | 6 | Medium | Optimize workflow layout |

| Shipping | Loading products for delivery | 4 | Low | Streamline communication with logistics |

Tools and Technologies for Enhancing Assembly Efficiency

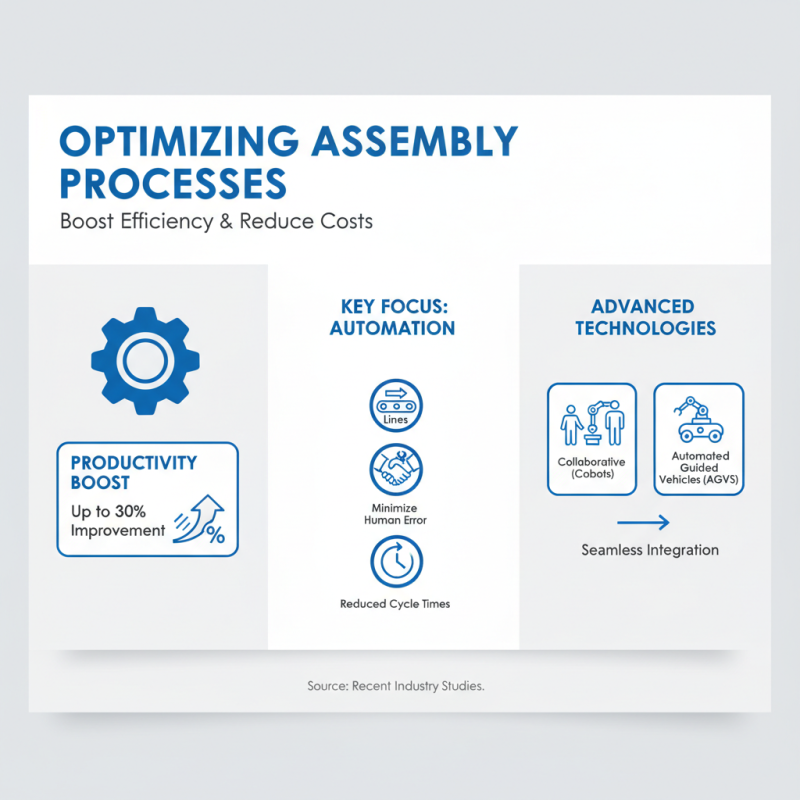

In today's fast-paced manufacturing environment, optimizing assembly processes is crucial for achieving efficiency and reducing costs. Recent studies indicate that companies that implement advanced tools and technologies can see productivity improvements of up to 30%. One key area to focus on is automation, which has been shown to streamline assembly lines, minimize human error, and reduce cycle times. Technologies such as collaborative robots (cobots) and automated guided vehicles (AGVs) are increasingly being adopted, allowing for seamless integration of robots into the workforce alongside human operators.

Furthermore, data analytics and IoT (Internet of Things) are transforming how assembly efficiency is monitored and enhanced. By collecting and analyzing real-time data from the assembly line, manufacturers can identify bottlenecks and inefficiencies that were previously undetectable. According to a report from McKinsey, companies that leverage IoT technologies can expect up to a 25% reduction in operational costs due to improved resource management and predictive maintenance capabilities. The strategic use of augmented reality (AR) can also aid assembly workers by providing real-time guidance and training, thereby enhancing worker productivity and reducing the training time by as much as 50%. Embracing these innovative tools not only boosts efficiency but also helps in creating a more agile and responsive manufacturing environment.

Measuring and Analyzing Production Performance in Assembly

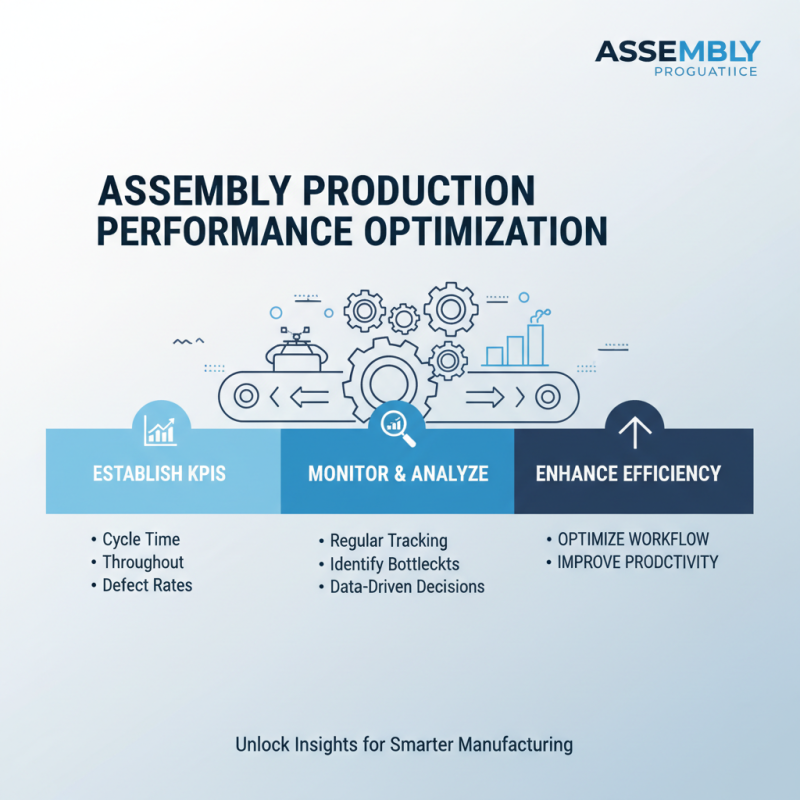

Measuring and analyzing production performance in assembly is crucial for optimizing workflow and enhancing efficiency. To start, key performance indicators (KPIs) should be established to provide a framework for assessing productivity. Metrics such as cycle time, throughput, and defect rates can offer valuable insights into how effectively the assembly line is operating. Regularly monitoring these KPIs allows for the identification of bottlenecks and areas requiring improvement, enabling teams to make data-driven decisions that enhance overall performance.

Furthermore, employing techniques like value stream mapping can facilitate a deeper understanding of the assembly process. By visualizing each step in the workflow, organizations can pinpoint inefficiencies and redundancies that might hinder production. This analysis not only aids in refining processes but also fosters a culture of continuous improvement. Engaging assembly workers in this analytical process can harness their hands-on experience, thus ensuring that proposed solutions are practical and directly address operational challenges. Through systematic measurement and analysis, companies can cultivate a more efficient assembly environment that drives productivity and quality.

Related Posts

-

Why Printed PCBs Are Essential for Modern Electronics Innovation

-

Top 10 Printed PCB Board Types for Your Electronics Projects

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses

-

2025 How to Choose the Best Circuit Board Components for Your Projects

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

Top 2025 Wire Harness Trends: Innovations and Essential Applications