Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

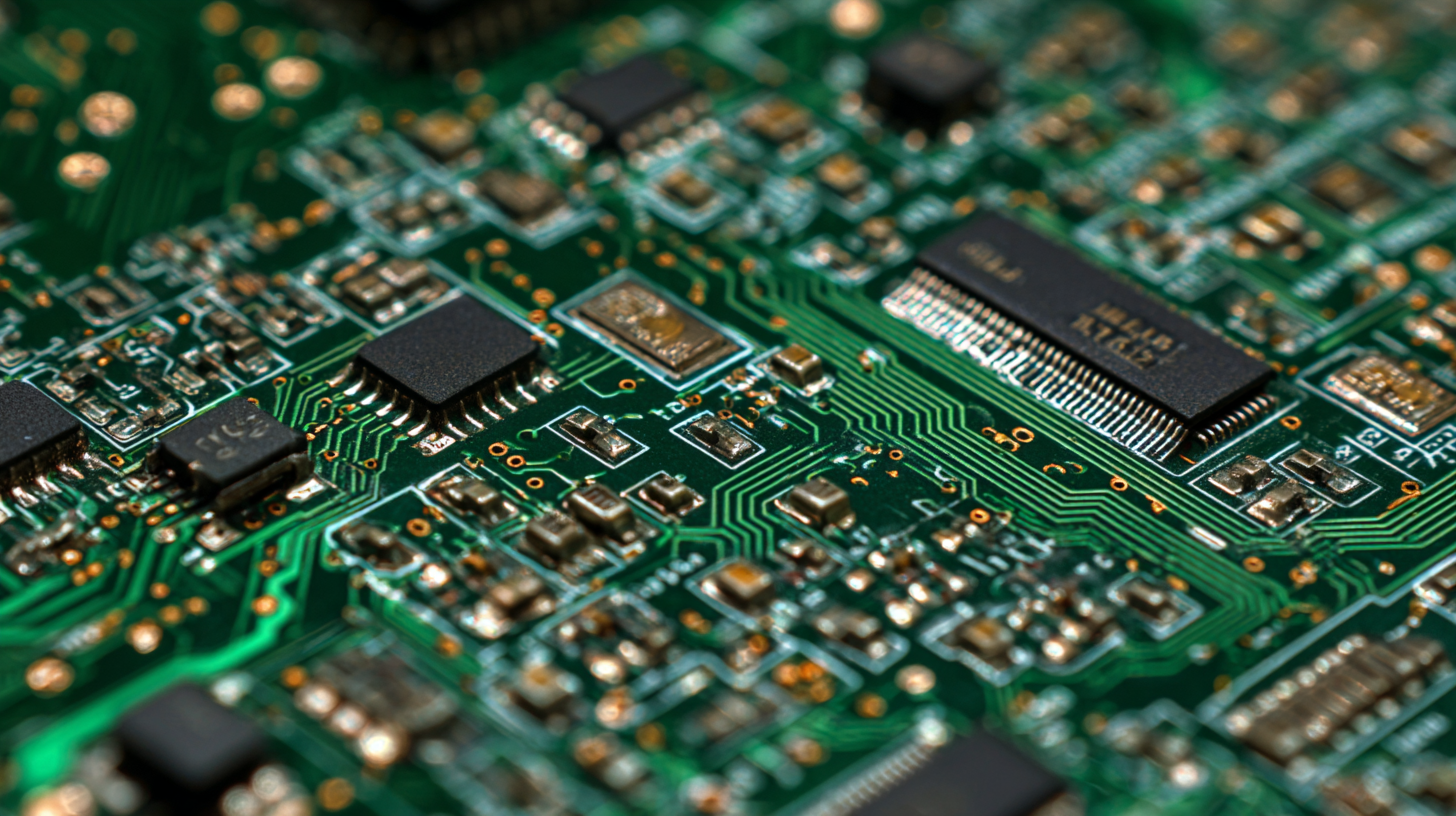

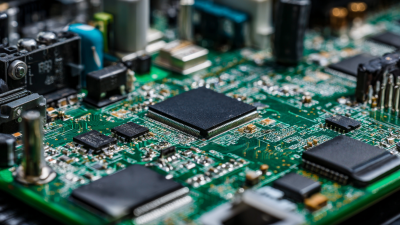

Understanding the Future of Printed Circuit Technology in Everyday Devices

As we delve into the future of printed circuit technology in everyday devices, it is essential to recognize the rapid evolution of this critical component. According to a recent market research report by Fortune Business Insights, the global printed circuit board (PCB) market is projected to reach a staggering $90 billion by 2026, growing at a CAGR of 4.9%. This growth is driven by the increasing demand for advanced electronics in sectors such as automotive, healthcare, and consumer electronics, where printed circuits play a pivotal role in functionality and performance.

As we delve into the future of printed circuit technology in everyday devices, it is essential to recognize the rapid evolution of this critical component. According to a recent market research report by Fortune Business Insights, the global printed circuit board (PCB) market is projected to reach a staggering $90 billion by 2026, growing at a CAGR of 4.9%. This growth is driven by the increasing demand for advanced electronics in sectors such as automotive, healthcare, and consumer electronics, where printed circuits play a pivotal role in functionality and performance.

Furthermore, the shift towards miniaturization and the integration of smart technologies into everyday devices underscore the need for innovative PCB designs that offer greater efficiency and reliability. As we explore the implications of these advancements, it becomes clear that understanding printed circuit technology is imperative for stakeholders aiming to stay ahead in this dynamic landscape.

Table of Contents

[Hide]

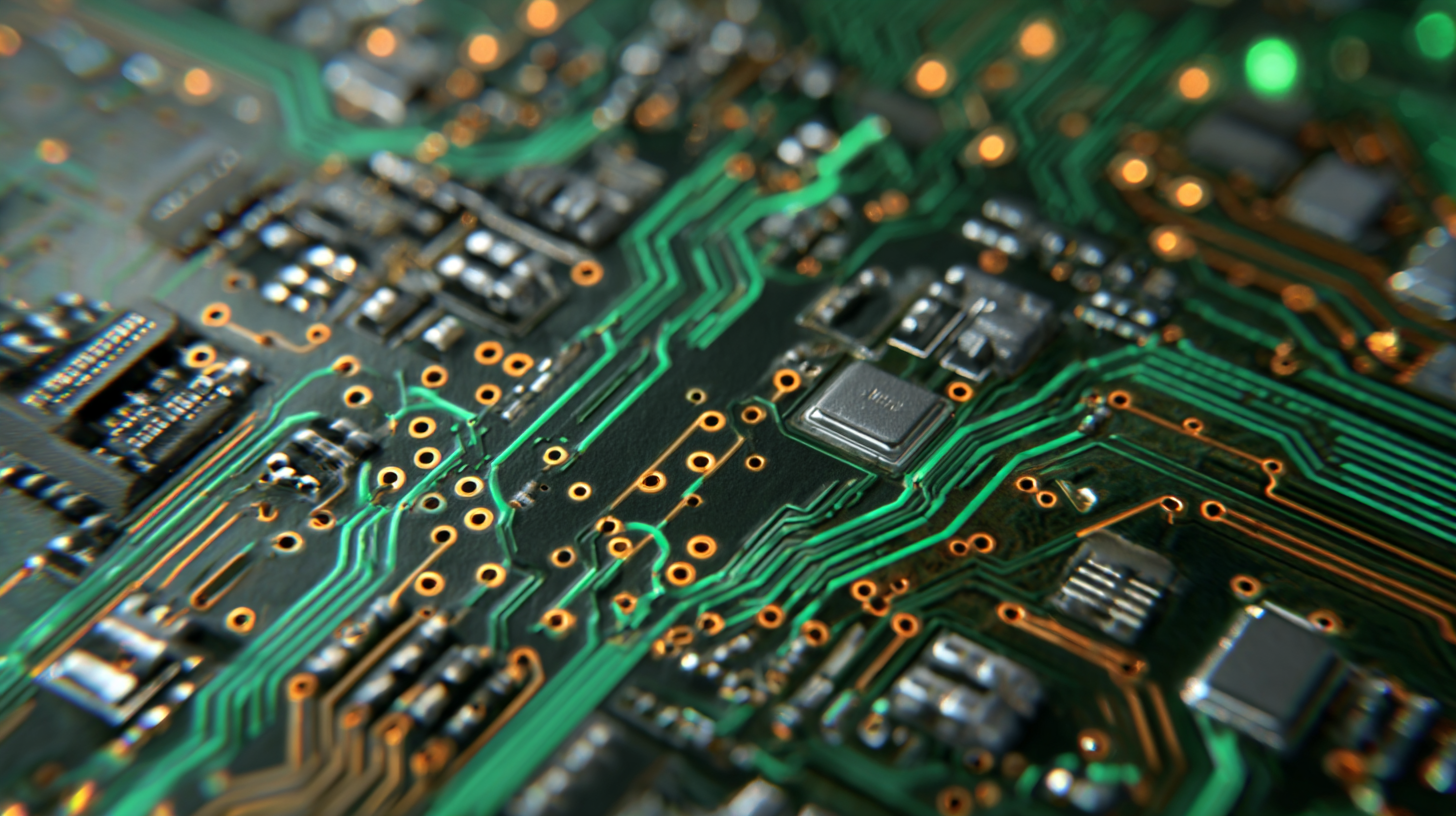

The Evolution of Printed Circuit Technology in Consumer Electronics

The evolution of printed circuit technology has profoundly transformed consumer electronics, enabling devices to become increasingly compact, efficient, and multifunctional. In the early days, circuit boards were large and cumbersome, primarily due to the limitations of materials and manufacturing processes. With the advent of surface mount technology (SMT) and innovations in materials science, manufacturers began to create smaller, lighter, and more complex configurations. This miniaturization allowed for the development of portable devices such as smartphones and tablets, fundamentally changing how consumers interact with technology.

Moreover, advancements in printed circuit technology have led to improved performance and reliability in everyday gadgets. Features such as multilayer circuit boards and flexible circuits have opened new avenues for design and functionality. For instance, wearable devices integrate sophisticated circuitry that can bend and adapt to the user’s movements. This adaptability, combined with enhancements in power management and signal integrity, supports the growing demand for smart devices that seamlessly connect and communicate. As the technology continues to evolve, we can expect even more innovations that will redefine our daily interactions with electronic systems.

Moreover, advancements in printed circuit technology have led to improved performance and reliability in everyday gadgets. Features such as multilayer circuit boards and flexible circuits have opened new avenues for design and functionality. For instance, wearable devices integrate sophisticated circuitry that can bend and adapt to the user’s movements. This adaptability, combined with enhancements in power management and signal integrity, supports the growing demand for smart devices that seamlessly connect and communicate. As the technology continues to evolve, we can expect even more innovations that will redefine our daily interactions with electronic systems.

Key Drivers Behind Innovations in Printed Circuit Design and Production

The OEM electronic assembly market is witnessing significant growth, driven by the increasing demand for advanced printed circuit technology across various sectors, notably automotive, communication, and medical applications. According to industry reports, the global market for printed circuit boards (PCBs) is projected to reach approximately $80 billion by 2026, growing at a compound annual growth rate (CAGR) of around 6% from 2021. This trend is primarily fueled by the rising need for miniaturization and increased functionality in electronic devices, translating into more innovative circuit designs.

Furthermore, the segmentation of the OEM electronic assembly market reveals a robust demand for hardware solutions compared to software, with automotive applications poised to lead in market share. Reports indicate that the automotive sector is expected to account for nearly 25% of the market by 2025, driven by advancements in electric vehicles and smart technologies that rely heavily on efficient PCB design and production techniques. Regions such as North America and Asia-Pacific are emerging as key players in the PCB manufacturing industry, supported by a growing focus on technological advancements and strategic investments in research and development.

Projected Growth and Market Trends for Printed Circuit Boards by 2025

The market for printed circuit boards (PCBs) is anticipated to undergo significant growth by 2025, driven by the increasing demand for electronics in both consumer and industrial applications. As technology continues to advance, devices are becoming more integrated, compact, and multifunctional, leading to an upsurge in PCB requirements. The rise of Internet of Things (IoT) devices, electric vehicles, and advanced telecommunications is expected to be a catalyzing factor in this growth, as these sectors rely heavily on efficient and reliable circuit designs.

Additionally, the market trends project an expansion fueled by innovations in materials and manufacturing processes. Companies are increasingly adopting flexible substrates and environmentally friendly materials that enhance the performance and sustainability of PCBs. This shift not only appeals to eco-conscious consumers but also complies with regulatory standards that are becoming stricter worldwide. As manufacturers invest in cutting-edge technologies to improve efficiency and reduce production costs, the PCB market is likely to witness robust growth, positioning itself as a critical component in the future of electronic device technology.

Projected Growth of Printed Circuit Technology by 2025

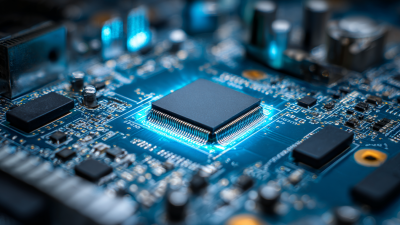

Impact of Miniaturization on Printed Circuit Technology for Smart Devices

The rapid advancement of technology has significantly influenced printed circuit technology, especially in the realm of smart devices. Miniaturization has become a critical component in this evolution, enabling manufacturers to create more compact and efficient circuits. According to a report from MarketsandMarkets, the global PCB market is expected to reach $85.7 billion by 2026, driven largely by the demand for miniaturized electronic devices. This trend not only enhances device performance but also opens doors for innovative designs that were previously thought impossible.

One of the key challenges in miniaturization is achieving high-density interconnects without compromising performance. The need for advanced materials and manufacturing techniques is paramount. Research from IPC indicates that high-density PCBs with microvias can improve signal integrity and allow for smaller form factors, thus aligning perfectly with the needs of the smart device market. As electronics continue to shrink, the integration of advanced technologies such as flexible circuits and embedded components is likely to revolutionize product design.

**Tip:** When designing devices with miniaturized PCBs, consider utilizing multi-layered designs to maximize space without sacrificing functionality. Additionally, keep an eye on emerging materials like high-frequency laminates, which can significantly enhance performance in compact devices.

Understanding the Future of Printed Circuit Technology in Everyday Devices - Impact of Miniaturization on Printed Circuit Technology for Smart Devices

| Device Type | Average PCB Thickness (mm) | Miniaturization Impact (%) | Common Materials Used | Technology Trends |

|---|---|---|---|---|

| Smartphones | 0.8 | 30 | FR-4, Polyimide | Flexible PCBs, Embedded Components |

| Wearable Devices | 0.5 | 40 | Polyimide, Silver Nanowire | Textile Integration, Biocompatible Materials |

| IoT Devices | 0.6 | 25 | FR-4, Low-loss Resin | Integration of AI, Edge Computing |

| Smart Home Devices | 1.0 | 20 | FR-4, Thermoplastic Materials | Wireless Communication, Energy Harvesting |

| Drones | 1.5 | 15 | FR-4, Carbon Fiber | Lightweight Design, Enhanced Connectivity |

Sustainability Practices Shaping the Future of Printed Circuit Manufacturing

The shift towards sustainability in printed circuit manufacturing is gaining momentum, driven by increasing regulatory demands and consumer expectations. According to a report by ResearchAndMarkets, the global market for eco-friendly printed circuit boards is projected to reach $30 billion by 2025, highlighting the industry's commitment to sustainable practices. This shift not only minimizes environmental impact but also creates opportunities for manufacturers to innovate in materials and processes.

To integrate sustainability into printed circuit technology, companies are adopting practices such as using recyclable materials and reducing waste production. A study by the IPC Association revealed that 68% of electronics manufacturers are now implementing greener manufacturing processes, demonstrating a significant trend towards sustainability. This shift is not just beneficial for the environment but also enhances brand reputation, making it a win-win scenario for businesses.

**Tip:** Consider evaluating your supply chain for eco-friendly alternatives when sourcing materials. This not only contributes to sustainability but can also reduce costs in the long run.

**Tip:** Participate in workshops and training programs focused on sustainable design practices for circuits. Educating your team can lead to innovative solutions that lower the environmental footprint of your products.

Related Posts

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Understanding the Future of Electronic Board Assembly in Modern Technology