Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

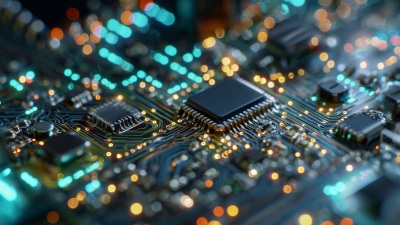

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

As we move further into the digital age, the convergence of technology and innovation is driving substantial transformations in the electronics industry. Central to this evolution is the advancement of PCB and assembly processes, which are becoming increasingly sophisticated to meet the demands of next-generation electronic devices.

According to a recent report from MarketsandMarkets, the global PCB market is projected to reach $86 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 3.5% from 2021. This growth is fueled by escalating demand for high-performance devices, including smartphones, wearables, and IoT applications. Moreover, the assembly technology sector is expected to grow at a similar pace, emphasizing the importance of efficient manufacturing techniques and materials to enhance productivity and sustainability.

As we explore the future of electronics, it is clear that advancements in PCB and assembly will play a pivotal role in shaping tomorrow's devices, enabling smarter, faster, and more efficient technologies.

Table of Contents

[Hide]

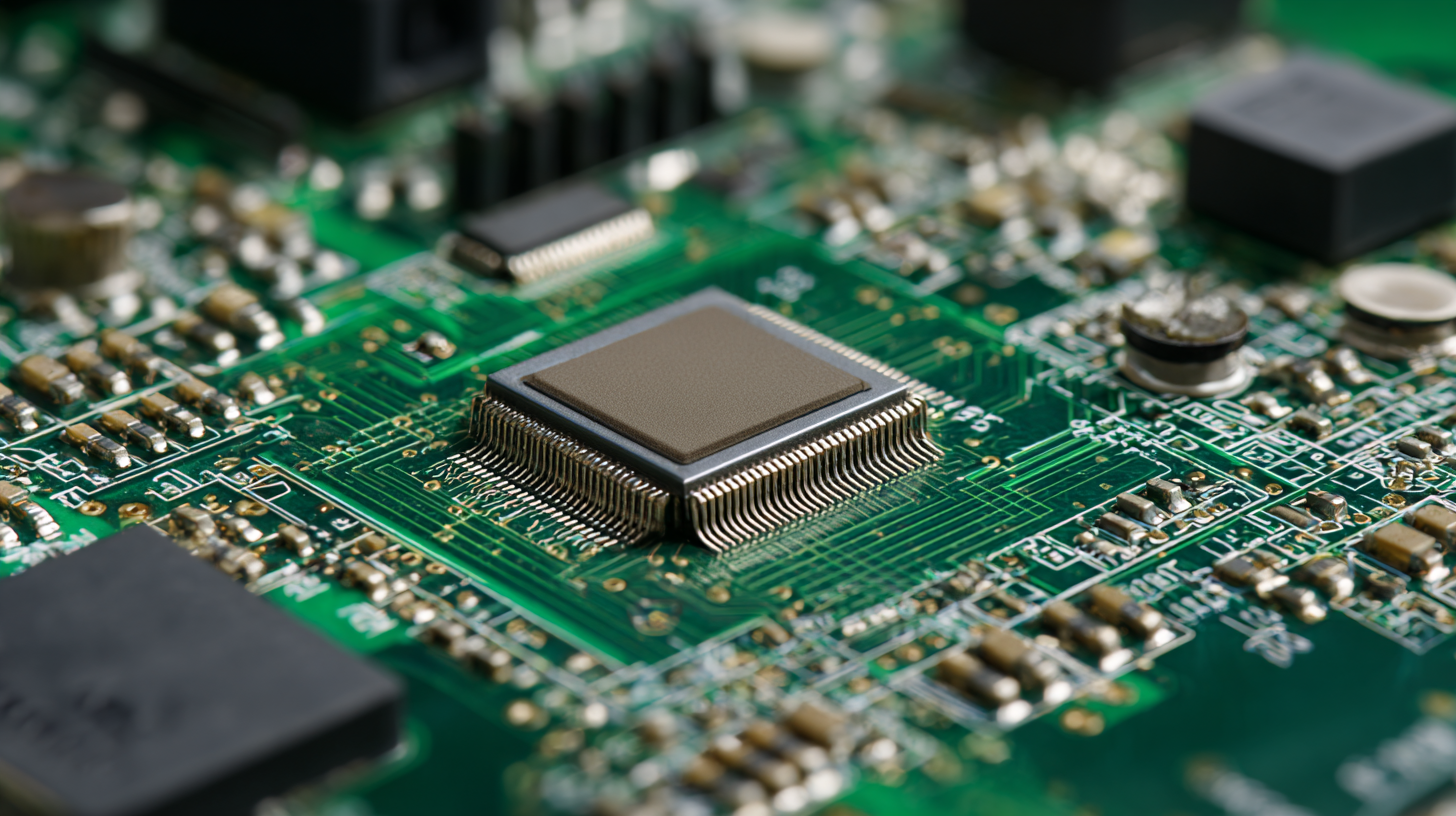

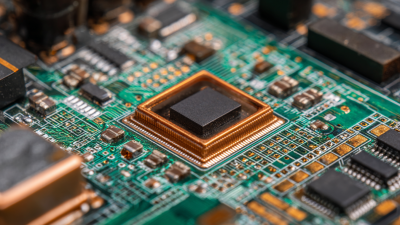

Understanding PCB Fundamentals: The Backbone of Modern Electronics

The backbone of modern electronics,

printed circuit boards (PCBs) play a crucial role in the functionality and design of today's advanced devices.

With the increasing demand for silicon chips driving market growth, PCBs are being adapted and optimized

to meet the requirements of various applications. These applications range from

wearable technology to flexible displays and even implantable electronics.

The rise of double-sided flexible printed circuits (FPCs) reflects the industry's shift towards

lightweight, compact designs

that enhance device capability without compromising performance.

As the electronics manufacturing landscape evolves, the integration of sophisticated PCB technologies

is paving the way for innovations in sectors such as automotive electronics

and medical devices. The emergence of

power semiconductor embedded PCB technology

is a testament to this trend, offering enhanced performance for high-efficiency applications.

With ongoing advancements in materials and processes, the PCB market is set to witness significant growth,

particularly as industries race to develop smart and connected devices

that cater to the needs of the future.

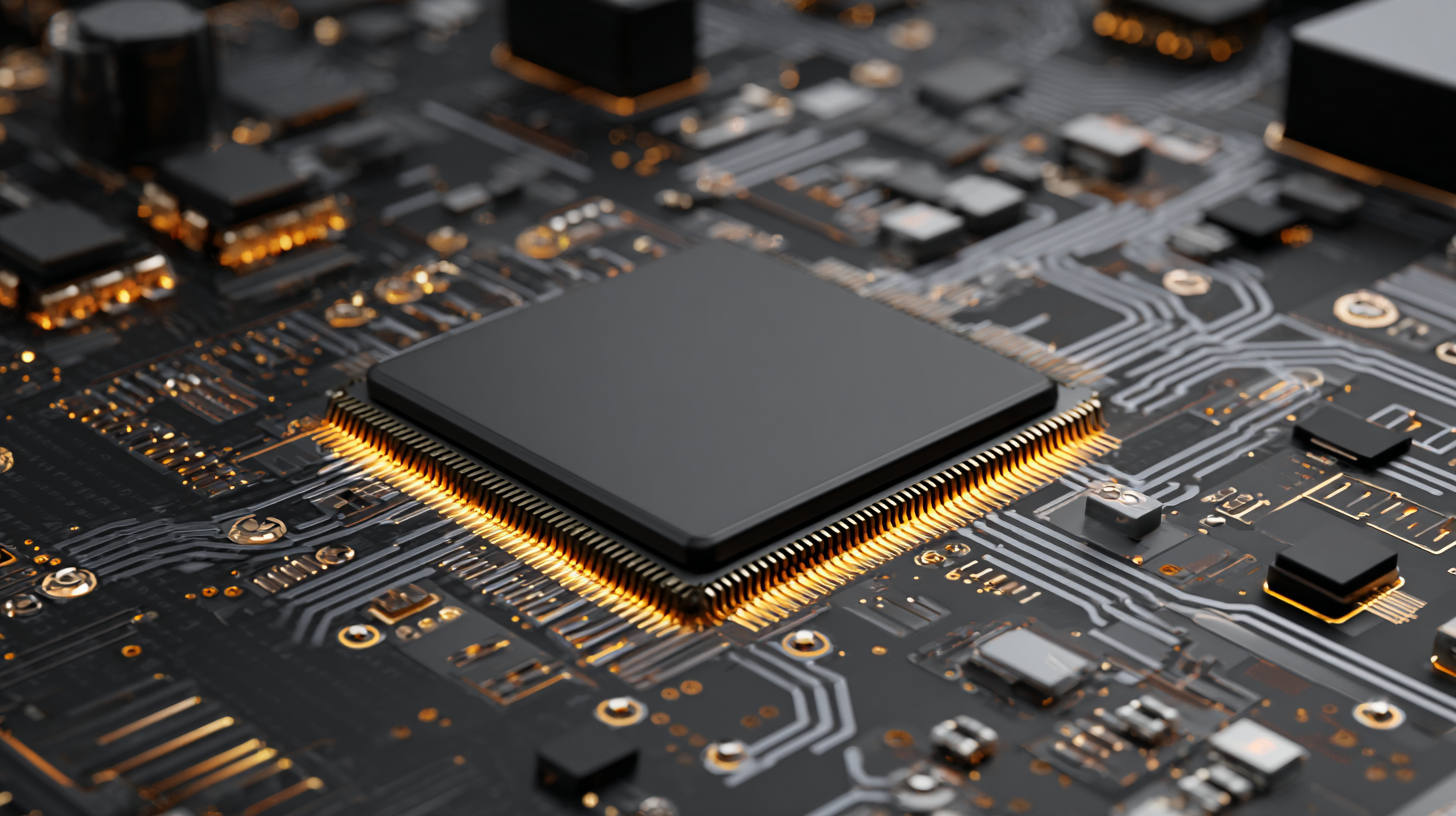

Innovative PCB Design Techniques for Enhanced Performance

Innovative PCB design techniques are increasingly essential for enhancing the performance of electronic devices. As the industry rapidly evolves, trends such as the adoption of rigid flex PCBs are gaining momentum, with the market projected to grow at a CAGR of 12.4%, reaching a valuation of $3.62 billion in China alone. This growth is fueled by the demand for more compact and efficient designs that meet the needs of modern applications. Advanced design software has also emerged as a critical tool, allowing engineers to create high-performance PCBs that accommodate the complexities of cutting-edge technologies.

Moreover, the integration of AI in PCB design is transforming traditional methodologies. AI-powered design automation simplifies the development process, enabling faster iterations and improved accuracy. With the PCB design software market expected to reach $12.11 billion by 2033, the focus on innovation in PCB design is evident. Companies that embrace these innovative practices will not only enhance their product offerings but also position themselves to capitalize on emerging opportunities in a competitive landscape.

The Future of Electronics: PCB and Assembly Technology Innovations

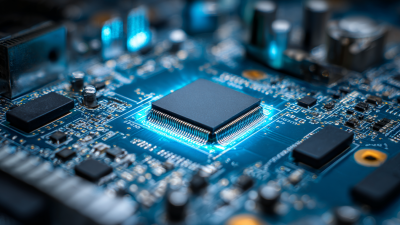

Assembly Processes: Automation and Its Impact on Production Efficiency

The landscape of electronics manufacturing is evolving rapidly, particularly with the integration of automation in assembly processes. The automation in Electronic Manufacturing Services (EMS) is projected to expand significantly, demonstrating a growth rate of approximately 8% annually, driven by advancements in robotics and smart technologies. By incorporating AI-driven solutions, manufacturers are achieving higher production rates and improved precision in item assembly, ultimately enhancing overall production efficiency.

Moreover, AI is revolutionizing the traditional factory floor, leading to a paradigm shift in production dynamics. Companies are increasingly leveraging robotic automation for intricate tasks such as surface finishing, which not only addresses labor shortages but also elevates the quality of final products. According to recent reports, organizations implementing AI in their assembly processes report efficiency gains of up to 30%, showcasing the technology's potential to streamline operations and reduce costs. This significant transformation emphasizes a future where automation is not just an option but a necessity for competitiveness in the electronics sector.

Moreover, AI is revolutionizing the traditional factory floor, leading to a paradigm shift in production dynamics. Companies are increasingly leveraging robotic automation for intricate tasks such as surface finishing, which not only addresses labor shortages but also elevates the quality of final products. According to recent reports, organizations implementing AI in their assembly processes report efficiency gains of up to 30%, showcasing the technology's potential to streamline operations and reduce costs. This significant transformation emphasizes a future where automation is not just an option but a necessity for competitiveness in the electronics sector.

Integrating Advanced Materials in PCB Manufacturing for Future Devices

The integration of advanced materials in PCB manufacturing is revolutionizing the design and functionality of tomorrow's electronic devices.

A recent report from Research and Markets indicates that the global PCB market is expected to grow from $72 billion in 2022 to over $100 billion by 2027, driven largely by the increasing demand for more sophisticated electronic components. As manufacturers explore materials such as high-frequency laminates, flexible substrates, and eco-friendly options, they are enhancing performance while addressing sustainability concerns.

To remain competitive, companies must adopt the latest advancements in PCB technology. One effective tip is to invest in advanced simulation tools that enable engineers to test new materials and designs before production. This not only shortens the development cycle but also minimizes costly errors that can arise from outdated processes. Additionally, collaborating with material suppliers can provide insights into cutting-edge innovations that can be integrated into your designs.

As the industry leans toward miniaturization and higher power density, utilizing advanced materials is crucial. For instance, using high thermal conductivity substrates can significantly improve thermal management in high-performance applications. By adopting these strategies, manufacturers can ensure their products are future-ready and aligned with the evolving demands of the electronics market.

Sustainability in Electronics: Eco-Friendly Practices in PCB and Assembly Technology

As the demand for electronics continues to rise, the industry is increasingly focused on sustainability to minimize environmental impacts. Recent studies indicate that the global printed circuit board (PCB) market is expected to reach $80 billion by 2025, with a significant shift towards eco-friendly practices. Companies are now prioritizing the use of recyclable materials and non-toxic substances in their PCB manufacturing processes. According to a report by IPC, over 90% of manufacturers are adopting green manufacturing initiatives, which not only reduce waste but also enhance the overall lifecycle of electronic devices.

Moreover, the assembly technology sector is innovating to align with sustainability goals. Implementing advanced automation techniques can significantly reduce energy consumption during the assembly process. A report from McKinsey highlights that companies adopting energy-efficient practices can lower operational costs by up to 30%. Additionally, sustainable soldering materials and techniques are being developed to ensure that assembly processes have a minimal ecological footprint. Through these innovative approaches, the electronics industry is not only reshaping the future of devices but also paving the way for a more sustainable planet.

Related Posts

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses