Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

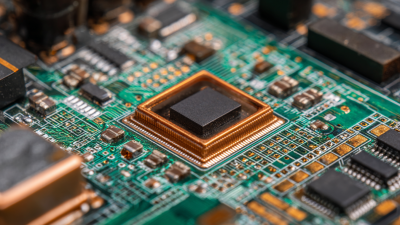

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

The journey of PCB fabrication has transformed dramatically over the years, evolving from rudimentary concepts into the sophisticated processes that underpin modern electronics. As the backbone of countless devices, printed circuit boards (PCBs) have witnessed significant advancements that address both the increasing demand for miniaturization and enhanced functionality. Initially, PCB fabrication relied on manual methods and basic materials, limiting the integration of complex circuitry. However, the advent of digital technologies and innovative fabrication techniques has revolutionized this field, allowing for greater precision, efficiency, and scalability. This exploration delves into the key milestones and technological breakthroughs in PCB fabrication, highlighting how these developments not only meet the challenges of contemporary electronic design but also pave the way for future innovations in the industry. By understanding the evolution of PCB fabrication, we can appreciate the intricate dance between engineering creativity and technological prowess that defines the modern electronics landscape.

Table of Contents

[Hide]

The Historical Journey of PCB Fabrication Techniques

The historical journey of PCB fabrication techniques showcases a remarkable transformation, marked by continuous innovation and adaptation to the evolving demands of the electronics industry. Initially, PCBs were crafted using rudimentary methods involving manual etching and wire connections. The introduction of photolithography in the 1960s represented a significant leap, as it allowed for more complex and reliable circuit designs. As data from the IPC (Institute for Interconnecting and Packaging Electronics) indicates, PCB production has seen a compounded annual growth rate (CAGR) of approximately 3% in recent years, reflecting the increasing integration of electronics in diverse applications.

The push toward miniaturization and increased functionality in electronic devices has further accelerated advancements in PCB manufacturing techniques. Innovations such as surface mount technology (SMT) and multi-layered boards have become standard, enabling the production of smaller, more efficient components. According to a report by MarketsandMarkets, the global PCB market is projected to reach $87.8 billion by 2025, driven by trends like IoT, automotive electrification, and the proliferation of smart devices. This journey from basic fabrication to sophisticated, automated processes emphasizes not only the technical progress but also the critical role that PCBs play in bringing modern electronic concepts to life.

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

| Year | Technique | Description | Impact on PCB Fabrication |

|---|---|---|---|

| 1950s | Manual Soldering | Hand-soldered components onto copper foil. | Introduced early PCB assembly; prone to human error. |

| 1960s | Photoengraving | Used light-sensitive film to create circuit patterns. | Improved precision and repeatability in PCB manufacturing. |

| 1970s | Multi-layer PCBs | Integration of multiple layers to increase complexity. | Allowed more compact designs for electronic devices. |

| 1980s | Surface-Mount Technology (SMT) | Components mounted directly on the surface. | Reduced size and cost of PCB manufacturing. |

| 1990s | Computer-Aided Design (CAD) | Software used for PCB layout and design. | Enhanced design capabilities and reduced errors. |

| 2000s | Rapid Prototyping | Quickly producing prototypes using new technologies. | Accelerated innovation and product development cycles. |

| 2010s | Additive Manufacturing | 3D printing technology applied to PCB fabrication. | Enabled complex geometries and reduced waste. |

Key Innovations That Shaped Modern PCB Manufacturing

The evolution of printed circuit board (PCB) fabrication has been significantly influenced by key innovations that have transformed modern electronics. Notably, the introduction of surface-mount technology (SMT) revolutionized how components are assembled on PCBs. SMT allows for much smaller components to be mounted directly onto the surface of the board, increasing density and enabling more complex circuit designs. This shift not only optimized space but also enhanced performance, as shorter electrical pathways reduced signal loss and improved overall reliability.

Another pivotal innovation in PCB manufacturing is the advancement of computer-aided design (CAD) tools. These sophisticated software programs enable engineers to create intricate layouts with precision, streamline the design process, and minimize errors. Coupled with automated fabrication techniques such as laser etching and 3D printing, CAD has accelerated production timelines significantly. The integration of these technologies has made it possible to produce high-quality PCBs at a faster rate, paving the way for rapid prototyping and the agile development of electronic devices, thus meeting the fast-paced demands of modern markets.

The Impact of Technology Advancements on PCB Design and Production

The ongoing advancements in technology are significantly reshaping the landscape of PCB design and production. The rise of AI applications, particularly in embedded design, is paving the way for smarter, more efficient PCB manufacturing processes. As generative AI gains traction, it promises to enhance the design workflow, enabling engineers to rapidly prototype and iterate on designs that seamlessly integrate into existing manufacturing systems. This evolution ties closely with a surge in demand for compact and high-performance electronic devices, galvanized by a global semiconductor investment boom projected to exceed a trillion dollars.

Moreover, the trend toward sustainable manufacturing practices and eco-friendly materials in PCB production reflects a broader commitment to environmental responsibility within electronics. Recent reports indicate that the PCB design software market is expanding significantly, driven by the need for rapid hardware innovation and AI-powered automation. As the electronics manufacturing sector embraces these trends, regions like Thailand are emerging as strategic hubs, leveraging AI investments to transform their production capabilities, thus highlighting a dynamic interplay between technological growth and global supply chain developments.

Sustainability Trends in PCB Fabrication: Challenges and Solutions

The evolution of PCB fabrication has embraced sustainability as a central theme, highlighting the pressing need to address environmental challenges while meeting the demands of modern electronics. With the rise of consumer awareness and regulatory pressures, manufacturers are increasingly focusing on eco-friendly materials and processes. Technologies such as bio-microsystem integration and Lab-on-PCB systems not only offer innovative solutions for compact electronics but also emphasize reducing waste and energy consumption throughout the lifecycle of PCB manufacturing.

The recent EIPC 2025 Winter Conference showcased a range of keynotes and discussions centered around sustainable practices in electronics manufacturing. From advancements in micro-total analysis systems (µTAS) to the integration of sustainable practices in production, attendees explored the myriad ways in which the industry can adapt. The conference served as a platform for startups and established companies alike, emphasizing the role of innovation in overcoming sustainability challenges and pointing towards a greener, more efficient future in PCB fabrication.

Future Directions in PCB Technology and Their Implications for Electronics

The future directions in PCB technology are poised to significantly reshape the electronics landscape, particularly in the automotive sector. A report anticipates that the global automotive PCB market will expand from USD 9.15 billion in 2023 to USD 15.1 billion by 2032, reflecting a compound annual growth rate of 5.9%. This growth is driven by the increasing complexity of modern vehicles, which integrate advanced communication systems and AI functionalities, necessitating sophisticated PCB designs that can support higher performance levels.

Additionally, as industries increasingly embrace smart technologies, the demand for high-layer-count PCBs is gaining prominence. The transition towards multi-layered PCBs indicates a broader trend towards greater integration and miniaturization in electronic components. This trend is further catalyzed by the advancements in 5G technology, which requires enhanced signal integrity and reduced interference, underscoring the need for innovative materials and manufacturing processes in the PCB fabrication landscape. With these developments, the future of PCB technology not only highlights a shift in manufacturing approaches but also emphasizes the crucial role of collaboration along the supply chain to deliver high-performance, reliable electronics.

Related Posts

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Understanding the Future of Printed Circuit Technology in Everyday Devices

-

Understanding the Future of Electronic Board Assembly in Modern Technology

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms