Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

10 Essential Tips for Successful Circuit Board Design

The significance of effective circuit board design cannot be overstated in today's rapidly evolving technological landscape. According to a recent report by the IPC (Association Connecting Electronics Industries), the global printed circuit board (PCB) market is projected to reach USD 75 billion by 2025, growing at a CAGR of 3.5%. This underscores the increasing demand for high-quality circuit board design solutions that meet the rigorous standards of various industries, including consumer electronics, automotive, and telecommunications.

As devices become more compact and multifunctional, the complexity of circuit boards has risen sharply, necessitating a more strategic approach to their design. Effective circuit board design not only ensures the functionality and reliability of electronic products but also impacts production efficiency and cost-effectiveness. A well-designed circuit board can lead to a reduction in manufacturing defects, improving yield rates by as much as 40%, as noted in a study published by the Journal of Electronic Materials.

In this context, understanding the best practices for circuit board design is crucial for engineers and designers alike. This article outlines 10 essential tips that can guide practitioners in navigating the complexities of circuit board design, ultimately leading to successful project outcomes and innovations in the electronics industry.

Table of Contents

[Hide]

Key Considerations for Material Selection in Circuit Board Design

When embarking on circuit board design, one of the most critical considerations is material selection. Choosing the right materials can greatly influence the performance, durability, and overall success of the final product. The substrate, for instance, is integral to supporting the circuit's electrical pathways, and selecting high-quality FR-4 or advanced materials like Rogers can enhance signal integrity and thermal performance.

A key tip for successful circuit board design is to thoroughly evaluate the thermal characteristics of the materials you plan to use. High-frequency applications may require materials with lower dielectric loss to minimize signal degradation. Additionally, ensure that the chosen materials can withstand the operational temperatures and environments the circuit board will encounter.

Another essential tip is to consider the mechanical properties of the materials during the design phase. Prioritize materials that can endure flexing and bending if your circuit board will be part of a portable device. Always consult with material suppliers and manufacturers to stay updated on the latest advancements in circuit board materials, which can lead to improved performance and reliability in your designs.

10 Essential Tips for Successful Circuit Board Design - Key Considerations for Material Selection in Circuit Board Design

| Tip Number | Design Consideration | Material Recommendation | Key Benefits |

|---|---|---|---|

| 1 | Thermal Management | FR-4 | Good thermal dissipation |

| 2 | Electrical Insulation | Polyimide | Superior insulation properties |

| 3 | Flexibility | Flexible PCB Material | Allows for compact designs |

| 4 | Cost Efficiency | CEM-1 | Lower production costs |

| 5 | Signal Integrity | High-frequency laminate | Enhanced signal performance |

| 6 | Durability | Epoxy resin | Long-lasting performance |

| 7 | Environmental Considerations | RoHS compliant materials | Reduced environmental impact |

| 8 | Manufacturability | Standard thickness materials | Easier production process |

| 9 | Weight Considerations | Lightweight substrates | Improved portability |

| 10 | Scalability | Modular designs | Facilitates future upgrades |

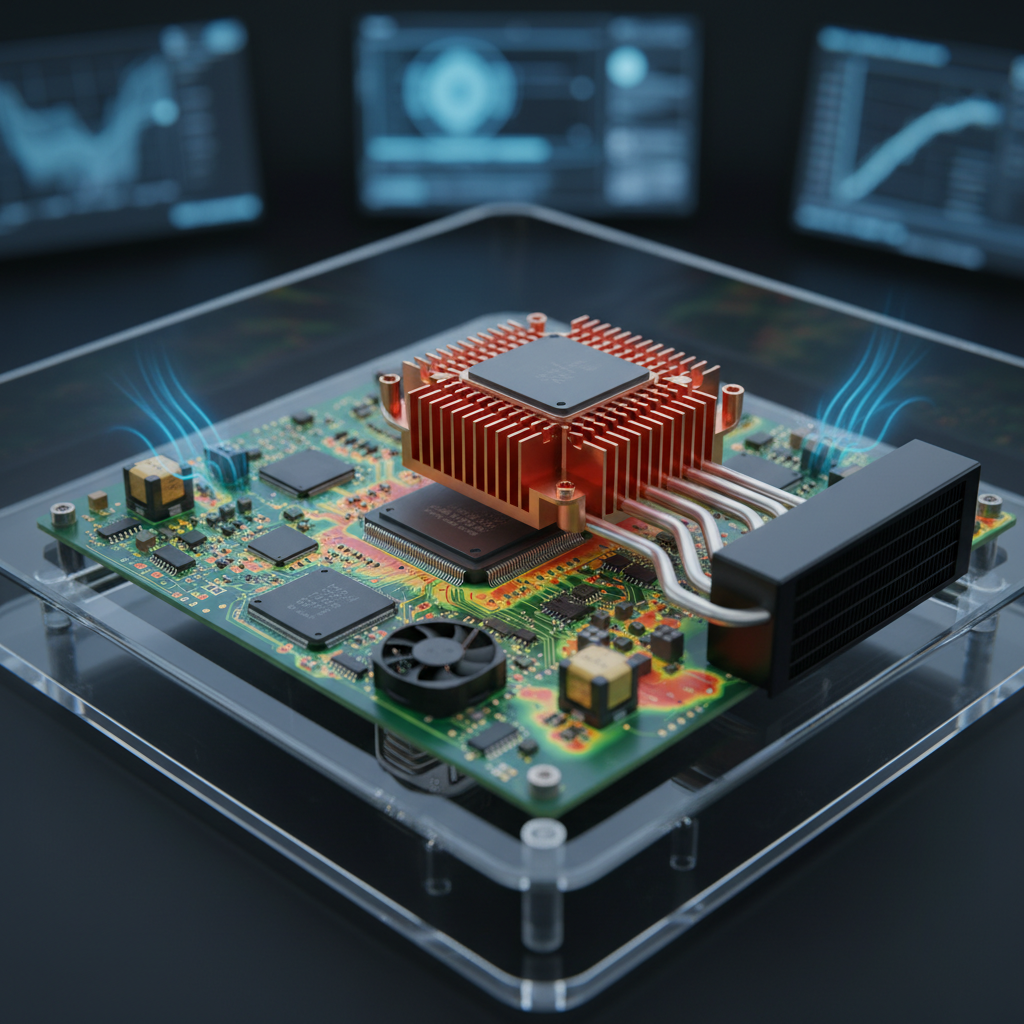

Understanding Thermal Management and Its Impact on Performance

Thermal management is critical in circuit board design as it directly impacts the performance and longevity of electronic devices. As components generate heat during operation, effective thermal management strategies become essential to prevent overheating, which can lead to failures. According to a 2022 report by IPC, non-optimized thermal management can result in a 20% increase in component failure rates, emphasizing the need for careful planning in the design phase.

One essential tip for successful circuit board design is to use thermal relief pads and vias. These features help dissipate heat from high-power components more effectively, ensuring a more uniform thermal distribution across the board. Additionally, selecting the right materials can significantly improve thermal conductivity; for instance, using copper with higher thickness can reduce thermal resistance. Another vital strategy is to incorporate thermal simulation tools early in the design process. A study by Mentor Graphics indicates that implementing thermal simulation can reduce the time spent on rework by up to 50%, making it a worthy investment for designers aiming to optimize device performance.

Furthermore, maintaining adequate spacing between components is crucial for heat dissipation. Redundant pathways for airflow can enhance the cooling process and improve overall thermal management. By embedding these practical tips into the design workflow, engineers can ensure their circuit boards not only meet performance expectations but also enhance reliability and lifespan.

Designing for Manufacturability: Cost Savings Through Thoughtful Layout

Achieving a successful circuit board design involves not only meeting functional requirements but also ensuring manufacturability. According to a report by IPC, nearly 30% of design issues arise during the manufacturing process, leading to significant cost overruns. Therefore, a thoughtful layout can significantly reduce production costs and improve time-to-market. Prioritizing manufacturability means selecting appropriate materials and components that align with available production technologies, thereby minimizing the need for costly adjustments later in the process.

Furthermore, integrating Design for Manufacturability (DFM) principles can lead to a reduction in manufacturing defects. A study published in the Journal of Electronic Packaging shows that implementing DFM techniques can decrease production errors by up to 20%. Factors such as optimizing trace widths and spacing, strategically placing components to minimize routing complexity, and ensuring proper thermal management all contribute to a board that is both cost-effective and high-performing. By emphasizing a manufacturability-focused design approach, engineers can achieve significant cost savings while enhancing the overall quality and reliability of the final product.

The Importance of Signal Integrity in High-Speed Circuit Boards

In the realm of high-speed circuit board design, signal integrity emerges as a pivotal factor that can significantly influence performance. According to a report published by IPC (Institute for Printed Circuits), improper signal integrity can lead to data transmission errors, which directly impact the reliability and efficiency of electronic devices. With the increasing clock rates of modern circuits, even minor signal degradation can result in substantial errors, making it imperative for designers to prioritize signal integrity from the outset.

High-frequency signals are particularly susceptible to issues such as crosstalk, electromagnetic interference (EMI), and reflections. A study by the IEEE reveals that up to 70% of signal integrity issues can be mitigated by employing suitable design strategies, such as controlled impedance routing and proper termination techniques. Additionally, as transceiver speeds rise—now exceeding 10 Gbps—ensuring a robust design that maintains signal quality across the circuit board becomes crucial. Designers equipped with a sound understanding of these principles can enhance performance metrics and maintain the competitive edge needed in the fast-paced electronics market.

The Role of DFM and DFT in Reducing Time-to-Market and Production Costs

In today’s competitive landscape, optimizing circuit board design is crucial for reducing time-to-market and production costs. The integration of Design for Manufacturing (DFM) and Design for Test (DFT) principles significantly enhances this process. DFM focuses on simplifying manufacturing processes, thereby minimizing production issues and costs. According to industry reports, implementing effective DFM strategies can lead to reductions in production costs by up to 30%, allowing companies to allocate resources to innovation and development more efficiently.

Simultaneously, DFT principles ensure that the circuit boards can be tested easily and effectively, which is vital in maintaining high-quality standards. This proactive approach to design not only accelerates production timelines but also diminishes the chances of costly rework and redesigns. Given the projected growth of the North American flight training market from $1.95 billion in 2024 to $4.23 billion by 2032, at a CAGR of 9.8%, the demand for reliable electronic systems will escalate. By incorporating DFM and DFT in circuit board design, manufacturers can meet evolving market demands while ensuring cost-effectiveness and product reliability.

10 Essential Tips for Successful Circuit Board Design

This bar chart represents the importance level of 10 essential tips for successful circuit board design. Tips that incorporate Design for Manufacturing (DFM) and Design for Testability (DFT) principles are highlighted as crucial for reducing time-to-market and production costs.

Related Posts

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

Why Printed PCBs Are Essential for Modern Electronics Innovation

-

Why Printed Board Assembly is Essential for Modern Electronics Manufacturing