Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top 10 Essential Tips for Efficient Wire Harness Assembly Processes

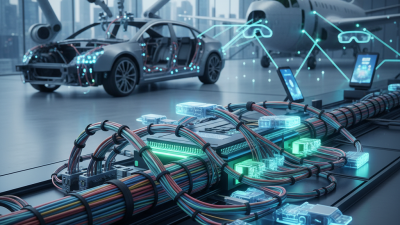

In the intricate world of manufacturing, the efficiency of wire harness assembly processes stands out as a crucial element for success. Industry expert John Smith, a veteran with over 20 years of experience in electrical engineering, emphasizes, “A streamlined wire harness assembly process not only enhances productivity but also significantly reduces the margin for error.” This insight highlights the importance of refining assembly techniques to meet the fast-paced demands of today’s markets.

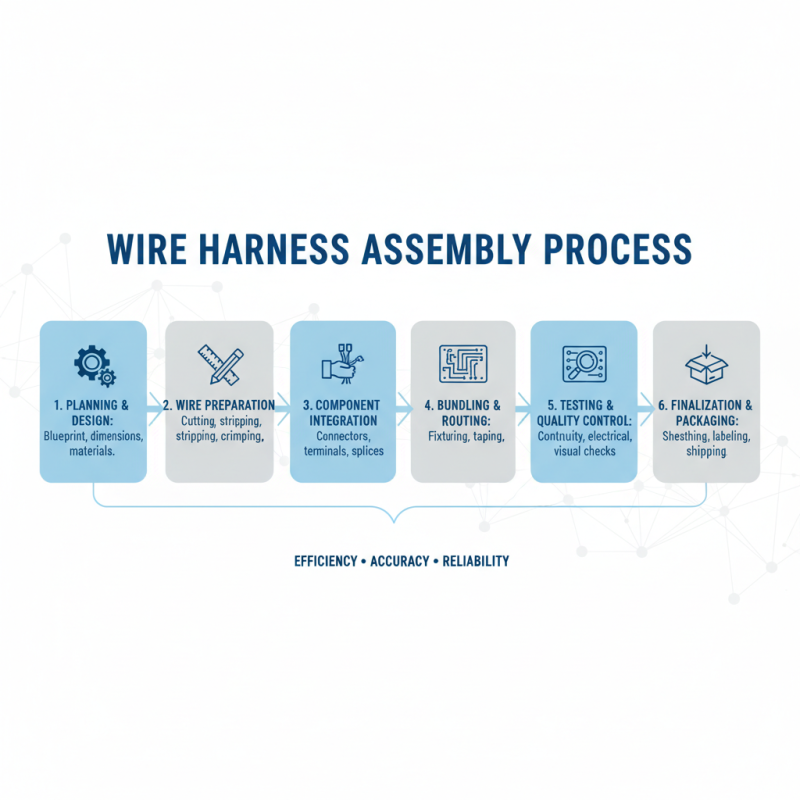

The wire harness assembly process involves various steps, from design and prototyping to the final assembly and testing of the harness. As complexity in electronic systems increases, so does the need for precision and efficiency in wire harness assembly. By adopting best practices and innovative strategies, manufacturers can ensure that their assembly lines maximize output while minimizing waste, ensuring high-quality results.

This article will delve into the top 10 essential tips for optimizing wire harness assembly processes. By implementing these strategies, businesses can improve their operational effectiveness, ultimately leading to enhanced overall performance and customer satisfaction. Whether you are a newcomer to the industry or a seasoned professional, these insights will serve as a valuable resource in navigating the evolving challenges of wire harness assembly.

Table of Contents

[Hide]

Understanding the Basics of Wire Harness Assembly Techniques

Wire harness assembly is a critical process in numerous industries, where structured wiring assemblies provide power and connectivity for electronic devices and automotive applications. Understanding the basic techniques of wire harness assembly is essential for achieving efficiency and accuracy. The process typically begins with precise planning, where the dimensions of the harness, the type of wires and connectors needed, and their arrangement are mapped out meticulously. This blueprint not only aids in avoiding mistakes but also streamlines the assembly process.

Once the planning phase is complete, the selection of materials takes center stage. High-quality wires, connectors, and insulation materials are essential for the longevity and reliability of the harness. Techniques such as proper wire stripping, crimping, and soldering play a significant role in ensuring that electrical connections are secure and capable of withstanding environmental factors. Additionally, understanding how to properly route wires and maintain organization throughout the assembly can significantly reduce assembly time and enhance overall product performance. With a solid grasp of these fundamental techniques, teams can enhance their workflow and ensure the production of robust wire harness assemblies.

Key Tools and Equipment for a Successful Wire Harness Assembly

In the world of wire harness assembly, having the right tools and equipment is crucial for achieving efficiency and accuracy. Basic tools such as wire cutters, strippers, and crimpers are essential for preparing and connecting wires. A good crimping tool, in particular, ensures strong and reliable connections, which are critical for the functionality and longevity of the harness. Additionally, using a high-quality wire stripping tool can enhance precision in removing insulation without damaging the wire itself, thereby decreasing the likelihood of connection failures.

Beyond handheld tools, investing in specialized equipment such as automatic wire cutting and stripping machines can significantly increase productivity. These machines streamline the process, minimizing manual labor and reducing the chances of human error. Furthermore, organizing tools in a well-structured work area with proper storage solutions can aid workers in quickly accessing the equipment they need, fostering a more efficient workflow. Overall, focusing on the right tools and proper organization lays the foundation for a successful wire harness assembly operation.

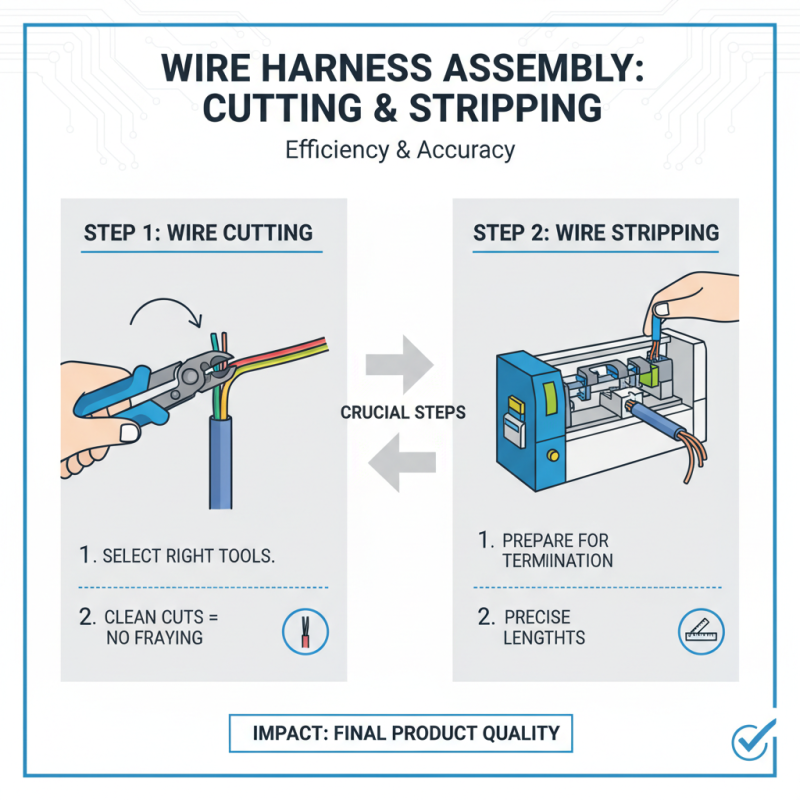

Step-by-Step Process for Accurate Wire Cutting and Stripping

Wire cutting and stripping are crucial steps in the wire harness assembly process that significantly affect the efficiency and accuracy of the final product. The first step involves selecting the right tools for cutting the wire. A well-designed wire cutter should provide clean cuts without fraying the wire ends, ensuring that the subsequent stripping process can be completed without complications.

When it comes to cutting, precision is paramount. Measure the wire lengths accurately before making cuts to avoid wastage and ensure consistency. Once you've completed the cutting, the next step is stripping the wire insulation. Use a quality wire stripper that matches the gauge of the wire you're working with. Set the stripper to the appropriate depth to remove the insulation without damaging the conductor beneath.

In addition, maintain a clean and organized workspace for optimal efficiency. Tips like regularly checking your tools for wear and tear can prevent delays caused by equipment malfunction. Establish a systematic approach to your assembly line, where each step flows into the next, keeping your team aligned and minimizing errors. Regular training and adherence to best practices will cultivate proficiency in cutting and stripping techniques, leading to a streamlined wire harness assembly process.

Best Practices for Effective Wire Connections and Insulation

In the world of wire harness assembly, ensuring effective wire connections and insulation is paramount. A study by the Institute of Electrical and Electronics Engineers indicates that poorly executed wire connections account for nearly 30% of electronic failures. One of the best practices for achieving reliable connections is to adhere to strict stripping and crimping specifications. Professionals recommend using calibrated tools to maintain consistency in wire preparation, as variations can lead to weakened connections. Additionally, employing modern crimping techniques, such as die-less crimping, can enhance the integrity of the connection and provide longer-lasting performance.

Insulation is another crucial factor in the wire harness assembly process. Data from the National Electrical Manufacturers Association show that insulation failure can lead to significant safety hazards and costly downtimes, which are estimated to affect over 15% of production schedules. To mitigate these risks, it is advisable to choose insulation materials that not only adhere to industry standards but also provide adequate resistance to temperature fluctuations and mechanical stress. Reinforcing wire bundles with heat-shrink tubing or braided sleeving can provide an extra layer of protection and improve overall reliability. By focusing on quality connections and robust insulation practices, manufacturers can enhance the efficiency and safety of their wire harness assemblies.

Top 10 Essential Tips for Efficient Wire Harness Assembly Processes

Quality Control Measures in Wire Harness Assembly Production

Quality control is a vital aspect of wire harness assembly production, ensuring that each component meets the necessary standards for functionality and safety. Implementing rigorous inspection protocols at every stage of the assembly process is essential. This includes initial checks of raw materials, in-process inspections during assembly, and final audits of the completed harnesses. Utilizing advanced testing techniques, such as continuity tests and electrical load tests, can identify potential issues early, reducing the risk of faulty products reaching the market.

In addition to testing, establishing clear documentation practices is crucial for maintaining quality control. This involves keeping detailed records of materials used, assembly procedures followed, and inspection results. By having comprehensive documentation, manufacturers can trace any defects back to their source and implement corrective actions more efficiently. Furthermore, training workers on quality standards and the importance of their roles in the assembly process fosters a culture of accountability that enhances overall production reliability. Empowering employees to take ownership of their work not only improves quality but also increases morale and job satisfaction.

Related Posts

-

Top 2025 Wire Harness Trends: Innovations and Essential Applications

-

10 Best Circuit PCB Manufacturing Services That Enhance Your Electronics Design Efficiency

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

How to Choose the Right Cable Harness for Your 2025 Project Needs

-

10 Essential Tips for Successful Circuit Board Design