Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

2026 How to Design Circuit PCB for Enhanced Performance and Reliability?

In today's electronics landscape, the design of circuit PCBs is crucial for enhanced performance and reliability. A recent report by the IPC shows that over 75% of PCB failures are linked to design flaws. This statistic underscores the need for meticulous attention to detail in circuit PCB design. With advancements in technology, designers must consider factors such as layout optimization, signal integrity, and thermal management. These elements play a pivotal role in ensuring systems function efficiently under various conditions.

One area often overlooked is the choice of materials. The right substrate can influence signal loss and the overall lifecycle of a circuit PCB. This point emphasizes the importance of educating designers on material properties. According to a study by the IEEE, almost 60% of design failures can be traced back to inadequate material knowledge. Engineers need to reflect on their choices and consider evolving materials that enhance performance.

Each design phase brings its challenges. Rapid prototyping is valuable but can lead to oversights. Designers frequently miss essential checks, which could significantly impact reliability. By embracing a more thorough review process, teams can identify potential flaws early. This proactive approach is vital to producing high-quality circuit PCBs that meet today's demanding standards.

Table of Contents

[Hide]

Importance of PCB Design in Enhancing Performance and Reliability

The design of printed circuit boards (PCBs) plays a crucial role in enhancing the overall performance and reliability of electronic devices. According to a report by the IPC, approximately 60% of electronic failures stem from poor PCB design. This highlights the importance of attention to detail in the design process. Optimizing PCB layouts can help minimize electromagnetic interference and improve signal integrity, ultimately leading to more dependable performance.

Tips for enhancing PCB reliability include:

1. Proper component placement: Components should be arranged based on their function and connectivity. Keep sensitive components away from noise sources.

2. Thermal management: Overheating can lead to performance issues. A study revealed that nearly 25% of PCB failures are linked to thermal problems.

Using multiple vias and ensuring robust grounding can greatly enhance performance. Connections that are too weak may fail when stress is applied. Regular design reviews can also prevent overlooked issues. Tight timelines may tempt teams to rush, but this often leads to mistakes. Incorporating thorough review stages could mitigate these risks and bolster the reliability of the final product.

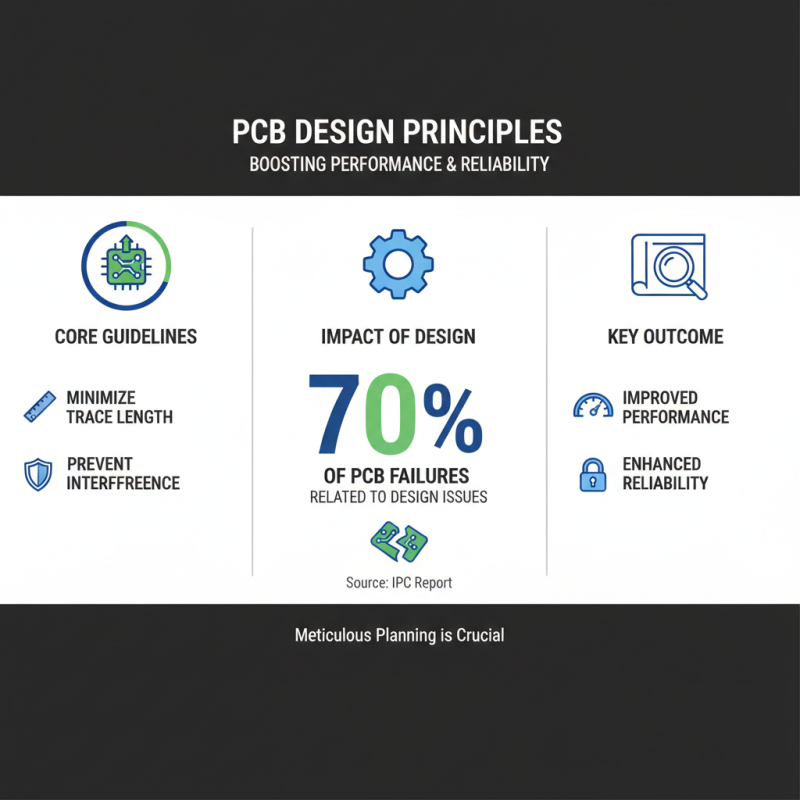

Key Design Principles for High-Quality Circuit PCBs

When designing circuit PCBs, the focus on key principles can dramatically improve both performance and reliability. High-quality layouts adhere to basic guidelines like minimizing trace length and preventing interference. According to a report by IPC, nearly 70% of PCB failures relate to design issues. This statistic highlights the importance of meticulous planning in the PCB design process.

Effective ground planes are crucial. They help minimize electromagnetic interference and improve signal integrity. Utilizing vias strategically can also help maintain a compact design while ensuring robustness. Over the years, industry studies have shown that PCBs with proper grounding can improve performance by up to 30%. However, achieving this requires continuous reflection on the design choices made.

Thermal management is another vital aspect. Improper heat dissipation can lead to component failure. Research indicates that 40% of PCB failures stem from thermal stress. Designers must consider airflow, heat sinks, and material selection carefully. These decisions can greatly impact long-term reliability. Thus, while good designs often follow trends, remaining flexible and adaptive is essential for ongoing improvement.

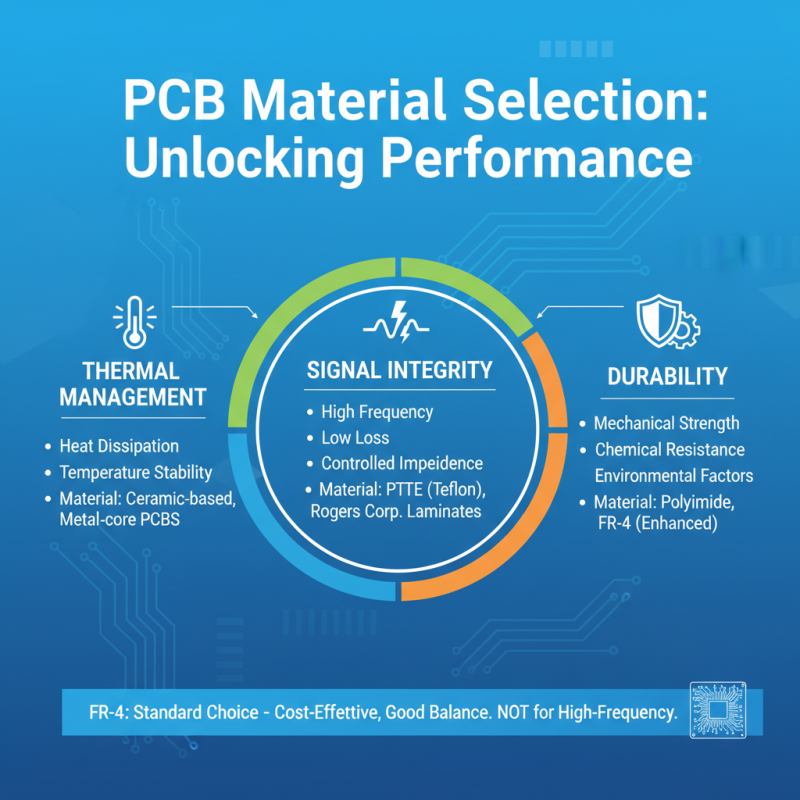

Material Selection and Its Impact on PCB Performance

Material selection plays a crucial role in PCB performance. Different materials offer unique properties that affect thermal management, signal integrity, and durability. For instance, FR-4 is a standard choice for general applications. It balances cost and performance well. However, this material may not perform optimally in high-frequency circuits.

Another option is using polyimide materials. They excel in high-temperature environments. Yet, they can be more expensive and difficult to process. Selecting the right material can increase the reliability of the PCB. Not all designs may consider environmental factors, leading to potential failures. This oversight can cause costly delays in the production process.

Further, the dielectric constant of materials impacts signal speed and strength. Using materials with inconsistent dielectric properties could lead to unexpected performance issues. Engineers must pay attention to these details during the design phase. Sometimes, the quick solution is not the best one. Exploring alternatives can open doors to better performance. Reflecting on material choices ensures their designs will stand the test of time.

Techniques for Effective Thermal Management in PCB Design

Thermal management is a crucial aspect of PCB design. It affects the longevity and performance of the circuit. Effective heat dissipation prevents overheating. High temperatures can lead to failures and reduced reliability. Engineers must consider various techniques to manage thermal issues in PCB layouts.

One effective approach is to use thermal vias. They help transfer heat from hot components to the ground plane. This can improve heat distribution significantly. Copper pours can also assist in conducting heat away. The choice of materials plays a vital role too. Some materials handle heat better than others, influencing overall performance.

Designing for thermal management is not always straightforward. A common pitfall is neglecting to analyze heat flow. Insufficient thermal simulation can lead to unexpected results. Engineers need to be vigilant about component placement. Clustering heat-generating parts can create hot spots. Regular checks and reviews during the design phase are essential.

Testing and Validation Methods for Reliable PCB Performance

Testing and validating PCB performance is crucial for reliability. According to a recent industry report, nearly 30% of PCB failures are linked to inadequate testing methods. Ensuring rigorous testing can significantly reduce these failures. Standard methods include thermal cycling, vibration tests, and electrical testing. Each method reveals different insights into potential weak spots.

For optimal reliability, consider these tips: Implementing real-time monitoring systems can catch issues early. Regularly review your testing protocols to adapt to new technologies. Also, conduct cross-functional tests that simulate end-user conditions. This approach often uncovers hidden design flaws that typical stress tests might miss.

A common oversight is underestimating the importance of environmental factors. Humidity, temperature, and mechanical stress can severely impact PCB performance. A study indicated that improper environmental controls can decrease the lifespan of PCBs by up to 40%. Regularly assess these factors. Build prototypes to test different materials and designs. This strategy aids in identifying areas for improvement before mass production begins.

2026 How to Design Circuit PCB for Enhanced Performance and Reliability? - Testing and Validation Methods for Reliable PCB Performance

| Testing Method | Purpose | Frequency | Key Performance Indicator (KPI) |

|---|---|---|---|

| Functional Testing | Evaluate all circuit functionalities | Every prototype cycle | Pass rate of functions |

| Thermal Testing | Assess heat dissipation and thermal stability | Quarterly | Maximum temperature rise |

| Electrical Testing | Measure electrical parameters such as resistance and capacitance | Monthly | Voltage drop across components |

| Environmental Testing | Simulate environmental conditions | Bi-annually | Operational integrity under stress |

| Reliability Testing | Determine long-term durability and performance | Annual | Mean Time Between Failures (MTBF) |

Related Posts

-

2025 Guide: How to Master Circuit Board Design for Optimal Performance

-

Top 10 Electronic Boards for Beginners in 2026?

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

10 Essential Tips for Designing High-Quality Printed PCB Boards Efficiently

-

2025 How to Choose the Best Circuit Board Components for Your Projects