Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Why Circuit Board Manufacturing Is Essential for Modern Technology Development

As we venture deeper into the realms of modern technology, the role of circuit board manufacturing emerges as a cornerstone for innovation and development. This intricate process not only forms the backbone of countless electronic devices but also drives advancements in various sectors, from telecommunications to healthcare. According to Dr. Emily Chen, a renowned expert in the field of electronics, "Without circuit board manufacturing, the technology we depend on today simply wouldn't exist." This statement encapsulates the essence of how integral circuit boards are to our daily lives and the continuous evolution of technological solutions.

In an era characterized by rapid technological advancements, ensuring the efficiency and reliability of circuit board manufacturing processes is critical. These printed circuit boards (PCBs) serve as the foundation for the functionality of smartphones, computers, and even complex machinery used in industries such as aerospace. The precision and quality achieved in circuit board manufacturing directly influence the performance and durability of the devices they inhabit. Therefore, as we delve into the significance of this industry, it becomes evident that a robust manufacturing ecosystem is vital for supporting ongoing innovation and meeting the growing demands of modern society.

Table of Contents

[Hide]

The Role of Circuit Boards in Modern Electronics

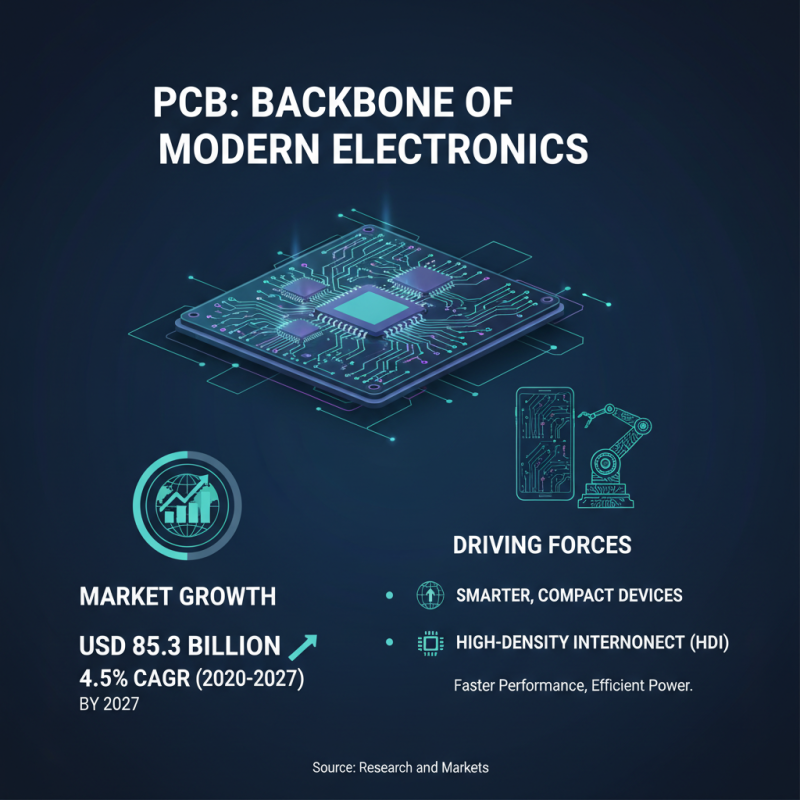

Circuit boards, often overlooked, are the backbone of modern electronics, pivotal to the functioning of everything from smartphones to advanced robotics. According to a report by Research and Markets, the global printed circuit board (PCB) market is expected to reach USD 85.3 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.5% from 2020. This growth is driven by the increasing demand for smarter and more compact electronic devices, which necessitate high-density interconnect (HDI) circuit boards that facilitate faster performance and more efficient power consumption.

The role of circuit boards in modern electronics cannot be overstated. They serve as the foundation that connects and supports various electronic components, allowing for signal transmission and power distribution within devices. The advancements in circuit board technology, such as the integration of flexible PCBs and multi-layer designs, have enabled the miniaturization of electronic components. A study by the IPC - Association Connecting Electronics Industries indicates that the average PCB fabrication process is becoming increasingly sophisticated, with innovations like advanced materials and manufacturing techniques reducing the size and enhancing the capability of devices. This shift not only enhances device performance but also contributes to the sustainability of electronic manufacturing by lowering waste and energy consumption — crucial factors in today’s environmentally conscious market.

Key Components of Circuit Board Manufacturing

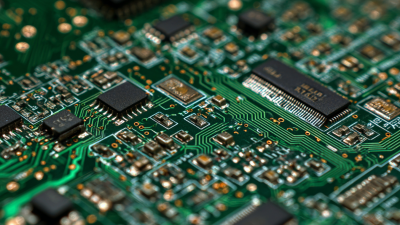

Circuit board manufacturing is a critical process that underpins the functionality of countless modern technologies. At the heart of this process are several key components that ensure reliable performance and integration into various electronic devices. First and foremost, substrate materials are pivotal in providing the foundational layer for circuit boards. These substrates, commonly made from materials like FR-4 or polyimide, offer both insulation and structural integrity, which are essential for efficient electrical signal transmission.

Another vital component is the copper foil used for conducting pathways. This thin layer of copper is meticulously etched to form circuits that allow electronic signals to travel seamlessly between different parts of a device. Additionally, the use of solder masks and silkscreen layers enhances the durability of circuit boards while ensuring clarity in the identification of components during assembly. Lastly, through-hole and surface-mount technologies facilitate the attachment of electronic components to the circuit board, combining both mechanical strength and efficiency in manufacturing processes. Together, these elements of circuit board manufacturing contribute significantly to the advancement and sustainability of modern technology.

Advancements in Circuit Board Technology and Their Impact

Advancements in circuit board technology are crucial to the evolution of modern electronics, as these boards serve as the backbone of virtually every electronic device. According to a report by Research and Markets, the global printed circuit board (PCB) market is projected to reach USD 78.58 billion by 2025, driven by the rising demand for sophisticated electronic devices in sectors like automotive, telecommunications, and consumer electronics. The push for miniaturization and enhanced performance has led to innovations such as high-density interconnect (HDI) PCBs, which offer improved signal integrity and reduced physical footprint, thereby enabling the development of smaller and more efficient devices.

Moreover, advancements in materials science have significantly impacted circuit board manufacturing. The introduction of materials like flexible PCBs allows for increased design versatility, enabling devices to conform to non-linear shapes and surfaces. According to a study by IPC, the adoption of these advanced materials leads to a 30-50% reduction in weight and size, which is particularly beneficial in mobile and wearable technology. Additionally, the shift towards environmentally friendly manufacturing processes and materials has made circuit board technology not only more sustainable but also aligned with global efforts to reduce electronic waste. As these trends continue, the relevance of circuit board manufacturing in the tech landscape will only grow, fueling further innovation and development across various industries.

Challenges in Circuit Board Production for High-Tech Applications

The production of circuit boards is a critical aspect of modern technology, yet it faces several significant challenges, particularly in high-tech applications. One primary issue involves the complexity of designs that continue to evolve with technological advancements. As devices become smaller and more powerful, circuit boards must accommodate denser and more intricate configurations. This leads to difficulties in achieving the necessary precision and reliability, requiring manufacturers to invest in advanced machinery and skilled labor.

Additionally, the demand for faster production cycles compounds these challenges. The rapid pace of technological innovation means that products must be developed and released more quickly than ever before. This urgency can strain manufacturing processes, leading to potential quality control issues and increased production costs. Moreover, as environmental regulations tighten, manufacturers must adapt their practices to minimize waste and energy consumption while still meeting the rigorous standards required for high-tech applications. Balancing these demands provides a complex landscape for circuit board manufacturers, necessitating continuous improvement and adaptation strategies.

Why Circuit Board Manufacturing Is Essential for Modern Technology Development - Challenges in Circuit Board Production for High-Tech Applications

| Dimension | Challenges | Impact on Technology | Solutions |

|---|---|---|---|

| Material Selection | Limited availability of advanced materials | Affects performance and durability | Research on alternative materials |

| Miniaturization | Difficulty in integrating components | Compromises functionality and service life | Advanced design methodologies |

| Quality Control | High defect rates | Impacts reliability of electronic devices | Automation and AI in inspections |

| Cost Management | Increasing production costs | Limits accessibility of technology | Lean manufacturing principles |

| Regulatory Compliance | Complexity of compliance requirements | Delays product launches | Dedicated compliance teams |

Future Trends in Circuit Board Manufacturing and Technology Development

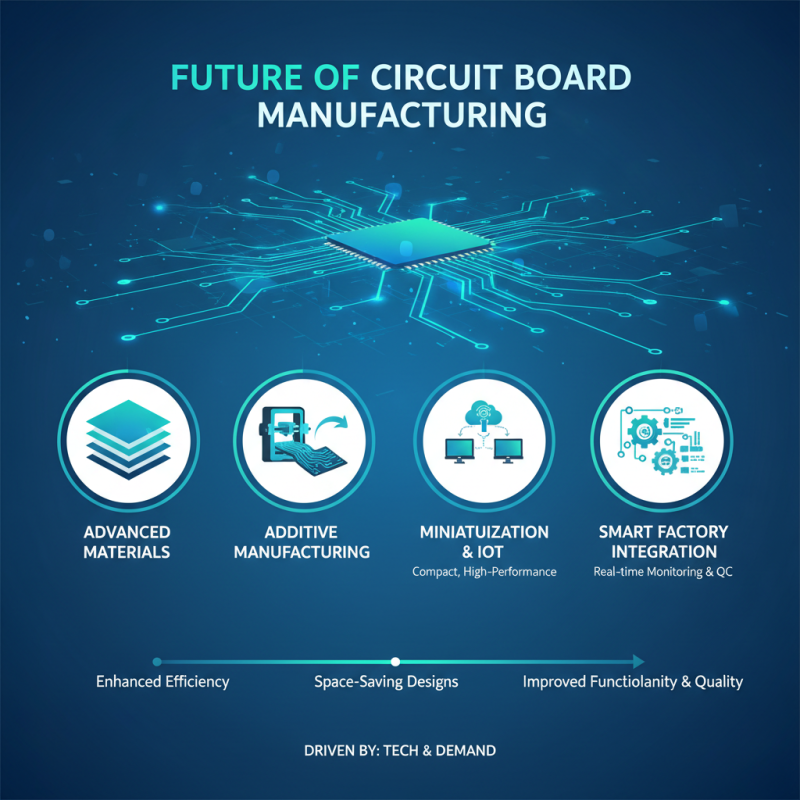

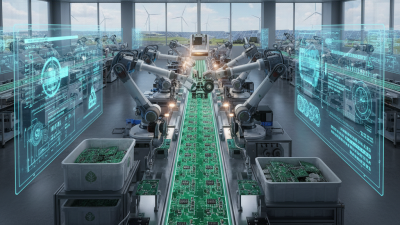

The future of circuit board manufacturing is poised for significant transformation, driven by advancements in technology and the increasing demand for compact, high-performance electronic devices. As industries continue to embrace miniaturization and the Internet of Things (IoT), manufacturers are exploring innovative materials and processes to enhance circuit board efficiency. Techniques such as additive manufacturing and flexible circuits are becoming more prevalent, enabling the creation of boards that not only save space but also improve functionality. Furthermore, the integration of smart technologies into the manufacturing process allows for real-time monitoring and improvements, thus increasing productivity and quality control.

Another trend shaping the future of circuit board manufacturing is the move towards sustainability. As environmental concerns grow, manufacturers are increasingly focusing on eco-friendly materials and processes to reduce waste and energy consumption. The development of biodegradable substrates and recycling programs for outdated circuit boards highlights the industry’s commitment to a greener approach. Additionally, advancements in automation and artificial intelligence are streamlining production lines, reducing labor costs, and minimizing the potential for human error. These trends collectively illustrate a vibrant future for circuit board manufacturing that aligns with the evolving needs of modern technology.

Related Posts

-

Understanding the Future of Printed Circuit Technology in Everyday Devices

-

Top 10 Essential Tips for Efficient Wire Harness Assembly Processes

-

Top PCB Assembly Trends to Watch in 2025 for Electronics Manufacturers

-

10 Essential Tips for Designing High-Quality Printed PCB Boards Efficiently

-

10 Essential Tips for Successful Circuit Board Design

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation