Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Why Is a Circuit Board Essential for Modern Electronics?

In today's digital age, the importance of the circuit board cannot be overstated. It serves as the backbone of modern electronics, enabling devices from smartphones to sophisticated medical equipment. According to a report by Allied Market Research, the global circuit board market is projected to reach over $75 billion by 2027, reflecting its pivotal role in technology.

Experts emphasize that "circuit boards are essential for connecting components and ensuring functionality." This statement by Dr. Emily Chen, a recognized authority in electronic engineering, underscores the fundamental nature of circuit boards in design and innovation. Without them, the progress in electronics could stall.

However, challenges remain. The industry faces issues like supply chain disruptions and environmental concerns related to manufacturing. Refining processes for better sustainability is critical yet, it requires collective effort. Acknowledging these challenges is important for driving future innovations in circuit board design and production.

Table of Contents

[Hide]

Understanding the Role of Circuit Boards in Electronic Devices

Circuit boards serve as the backbone of modern electronics. They hold components securely, creating paths for electrical currents. Every device relies on these printed circuit boards (PCBs) for functionality. Without them, our smartphones, computers, and home appliances would cease to operate.

The design of circuit boards can be intricate. They often feature layers of materials, including copper and fiberglass. These layers serve specific functions. However, errors in layout can cause malfunction. Designers must carefully consider the orientation and placement of each component. Mistakes can be costly and lead to device failures.

Not all circuit boards are the same. Some are simple, powering basic devices. Others are complex, fitting into advanced technology. The evolution of these boards reflects the rapid growth of electronics. Each generation brings improvements and new challenges to overcome. Understanding their role helps us appreciate the complexity behind everyday gadgets.

The Structure and Components of a Circuit Board

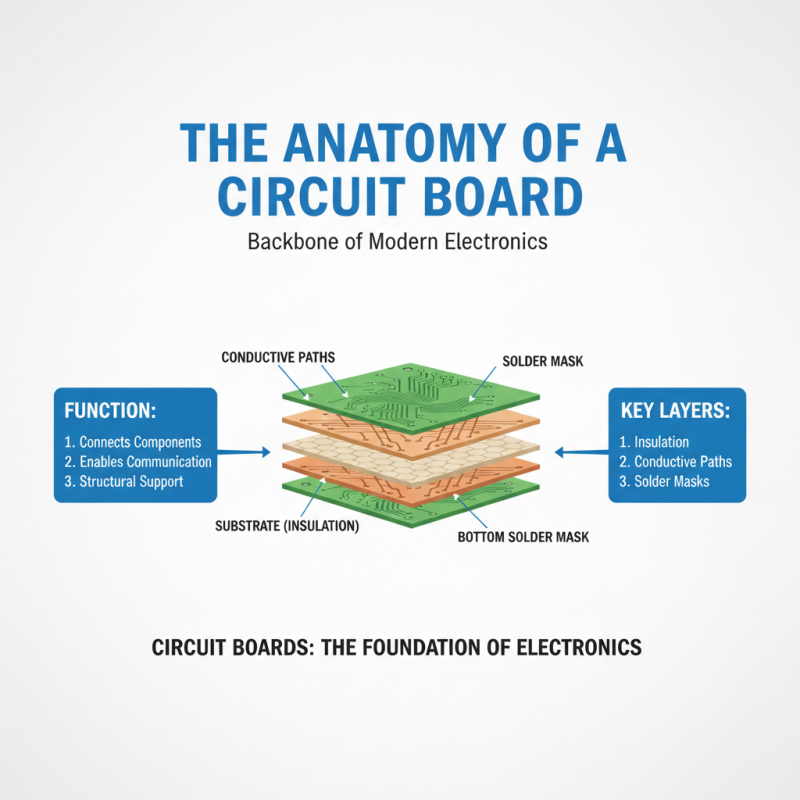

A circuit board is the backbone of modern electronics. It serves as a platform for electronic components to connect and communicate. The structure of a circuit board consists of several layers, typically including insulation, conductive paths, and solder masks. Each layer plays a critical role in functionality.

The most common type is the printed circuit board (PCB). Industry data indicates that the global PCB market was valued at approximately $60 billion in 2021, reflecting its essential nature in devices ranging from smartphones to industrial machinery. The copper traces on the board carry electrical signals, while capacitors, resistors, and integrated circuits provide essential functionality.

Despite advancements, circuit board production faces challenges. Quality control is crucial. Inconsistent manufacturing can lead to defects. For instance, a study found that up to 30% of circuit boards fail during initial testing due to poor solder joints or misalignment. Producing flawless circuit boards is a priority, yet imperfections still occur. This highlights the need for improved manufacturing techniques and better quality assurance processes.

How Circuit Boards Facilitate Electrical Connectivity

Circuit boards are the backbone of modern electronics. They provide a structured way to connect various components, allowing devices to function efficiently. Without these boards, it would be challenging to achieve the required electrical connectivity. The pathways etched on the board ensure that power and signals flow precisely where needed. This precise routing is crucial, especially in intricate devices.

Each circuit board is designed with specific needs in mind. For instance, the arrangement of components must consider both electrical efficiency and physical space. Mistakes in design can lead to poor performance or complete failure. It requires thoughtful planning and testing. Sometimes, even minor errors can cause significant issues. Issues like overheating or short circuits can arise if connections aren’t perfect.

Moreover, the material used in the circuit board plays a vital role. Different materials have distinct conductive properties, affecting performance. The choice of material can also impact the board's durability. There's always a balancing act between cost, performance, and durability. Designers must be strategic in their selections, which can be a tricky task. Creating a functional and reliable circuit board is a challenging but rewarding endeavor.

The Impact of Circuit Boards on Device Performance and Efficiency

Circuit boards are the backbone of modern electronics. They connect multiple components, allowing devices to function efficiently. A well-designed circuit board can enhance performance significantly. When components are arranged thoughtfully, signal integrity improves. This results in faster processing speeds and better battery life.

However, creating the perfect circuit board is not easy. Designers face challenges such as heat dissipation and electromagnetic interference. Mistakes in design can lead to poor performance or even device failure. A slight error in layout can cause outdated technology to underperform. Identifying and correcting these flaws requires expertise and significant resources.

In today's fast-paced market, efficiency is vital. Consumers demand devices that are not only fast but also reliable. A circuit board that performs well can determine the success of a product. As electronics evolve, so must the technology behind circuit boards. The quest for optimal design continues, presenting opportunities for innovation and improvement in the industry.

Why Is a Circuit Board Essential for Modern Electronics? - The Impact of Circuit Boards on Device Performance and Efficiency

| Dimension | Description | Impact on Performance | Efficiency Rating (1-10) |

|---|---|---|---|

| Material Type | The substrate used for the circuit board | Affects conductivity and thermal performance | 8 |

| Layer Count | Number of conductive layers on the board | Determines complexity of circuit design | 9 |

| Trace Width | Width of the conductive paths on the board | Impacts current capacity and heat generation | 7 |

| Signal Integrity | Quality of transmission of signals | Crucial for high-speed applications | 10 |

| Thermal Management | Techniques to dissipate heat | Prevents overheating and failures | 8 |

| Manufacturing Accuracy | Precision in creating the circuit board | Directly affects reliability and functionality | 9 |

Future Developments in Circuit Board Technology and Their Implications

The future of circuit board technology is exciting yet uncertain. As devices become smaller, the demand for more efficient circuit boards rises. This push leads to innovations like flexible circuit boards. These boards can fit into tiny spaces, enabling new designs. However, manufacturing them can be challenging and costly. Finding the right materials is crucial.

Trends point towards increased integration of AI in design processes. AI can help optimize layouts, reducing wasted space. But there is a concern about reliance on automation. Human oversight is still necessary to avoid errors. Additionally, new materials like bio-based substrates are emerging. They promise sustainability but require rigorous testing for reliability.

Quantum computing presents another frontier for circuit boards. This technology might change how circuits function at a basic level. Yet, scalability remains a significant issue. Can these advanced boards be produced at a reasonable cost? Industry experts are pondering this dilemma. The balance between innovation and practicality will shape future developments in circuit board technology.

Related Posts

-

2025 How to Choose the Best Circuit Board Components for Your Projects

-

Why Effective Board Design Matters for Successful Business Strategies

-

2025 Guide: How to Master Circuit Board Design for Optimal Performance

-

2026 Best Circuit Design Techniques for Innovative Engineers?

-

What is PCB and Assembly Process Explained for Beginners

-

The Future of Wire Harness Manufacturing Trends Innovations and Sustainability Practices