Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Choose the Best PCB Manufacturing Process for Your Project?

Selecting the right PCB manufacturing process is crucial for the success of any electronics project. According to a recent report by IPC, the global market for printed circuit boards is expected to reach $76 billion by 2026. This shows the increasing demand for high-quality PCBs across various industries, including consumer electronics and automotive sectors.

Choosing the best manufacturing process can be challenging. Factors such as material type, design complexity, and production volume all play a significant role. A report by Research and Markets indicates that nearly 40% of PCB failures arise from improper manufacturing techniques. This highlights the importance of understanding how each process impacts the final product.

Moreover, the rise of IoT devices demands advanced PCB technologies. As devices become smaller and more complex, the manufacturing process must adapt. Decisions made during the design phase can have significant long-term effects. Striking a balance between cost, quality, and efficiency is essential. Evaluating each PCB manufacturing option thoroughly can prevent costly mistakes.

Table of Contents

[Hide]

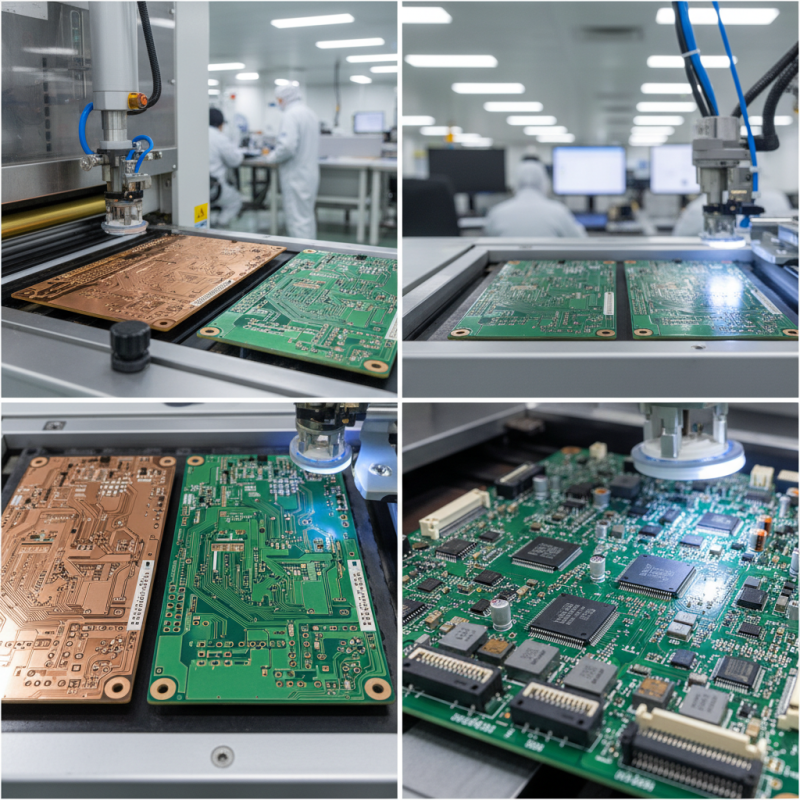

Understanding the Basics of PCB Manufacturing Processes

Understanding the basics of PCB manufacturing processes is essential for designers and engineers. A printed circuit board (PCB) is critical in electronic devices. It connects different components. According to a report by IPC, 42% of manufacturers cite the type of PCB fabrication as a key influence on product performance.

Various methods exist for PCB fabrication. The most common is subtractive manufacturing. This method involves removing material from a blank board. It can lead to waste. On the other hand, additive manufacturing adds material where needed. This reduces waste, but might not be suitable for high-volume production.

Another aspect to consider is the type of materials used. FR-4 is widely utilized, but its thermal performance can be inadequate in high-power applications. Many are now exploring alternative materials like polyimide, which offers better thermal resistance. However, these options can complicate the manufacturing process. Balancing cost, quality, and efficiency is a constant challenge in PCB production.

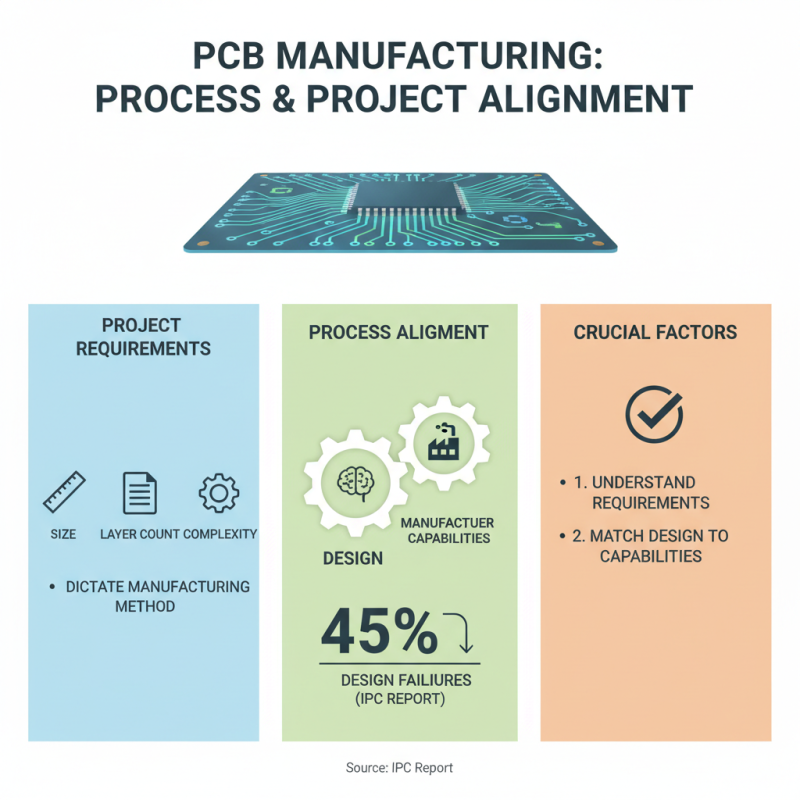

Identifying Your Project Requirements and Constraints

When choosing the best PCB manufacturing process, understanding your project requirements is crucial. Factors like size, layer count, and complexity can dictate the manufacturing method you should choose. For instance, a report from IPC noted that 45% of design failures stem from lack of process alignment. It's vital to ensure that your design matches the capabilities of the chosen manufacturer.

Additionally, budget constraints influence decision-making. A survey indicated that 70% of companies face budget overruns due to unexpected costs in PCB production. Consider aspects like material selection, which can significantly impact both cost and performance. For example, high-frequency boards typically require more expensive materials. Sometimes, making compromises leads to better outcomes. Shorter runs may benefit from simpler processes, even if that rushes some quality checks. Balancing performance and cost is often a challenging task.

Project timelines also create pressure. Tight deadlines might lead to overlooking potential issues in the manufacturing process. A study highlighted that 35% of developers wish they had more time for prototyping. Speed can compromise quality. It’s essential to weigh the urgency against the risks involved. Properly identifying these constraints can guide you toward a manufacturing process that meets your project goals efficiently.

Evaluating Different PCB Manufacturing Techniques

When evaluating different PCB manufacturing techniques, start by considering your project's requirements. Each method has its strengths and weaknesses. Techniques range from traditional methods to advanced ones like HDI. Think about factors such as complexity, volume, and budget.

For low volume production, consider prototyping techniques. They can save time and money. High volume projects might benefit from automated methods. However, quality control can be challenging. It’s crucial to weigh cost against quality.

Tip: Always prototype your design. Testing can reveal flaws early in the process. This prevents costly mistakes down the line.

Another option is selecting materials wisely. Different materials impact performance and durability. Some methods may require specific materials that fit your electrical needs. If you choose incorrectly, it could lead to failures.

Tip: Communicate with your manufacturer. Misunderstandings can arise. Clear communication helps clarify expectations and project timelines. This ensures a smoother production process.

Evaluating Different PCB Manufacturing Techniques

Comparing Costs and Turnaround Times for Various Methods

When selecting a PCB manufacturing process, costs and turnaround times vary widely across different methods. Traditional methods, like through-hole technology, are often cheaper for small batches. However, they may take longer due to manual assembly steps. In contrast, surface mount technology can reduce assembly time and cost for larger production runs. Yet, this efficiency comes at a higher initial setup cost, which can trip up new projects.

Tip: Evaluate your project requirements. If you're in a hurry, prioritize faster methods. Check if your budget allows for more expensive options that save time. Many designers overlook costs related to prototypes, leading to surprises later.

Moreover, consider the material choice and complexity of your design. More complex boards require advanced processes, which can drive up costs and lead times. A simple design may not need intricate methods, saving both time and resources.

Tip: Always get multiple quotes. Comparing prices and timelines can reveal great opportunities. Don't settle for the first option. Reflect on your design's future scalability too. A little foresight can prevent costly mistakes down the road.

Selecting the Right Manufacturer for Your PCB Project

When selecting a manufacturer for your PCB project, several factors come into play. Start by evaluating the manufacturer’s experience in your specific industry. This can significantly impact the quality of your PCB. Look for one with a strong track record in delivering reliable products. Communication is essential too. Choose a manufacturer that maintains open lines of communication. Quick responses show commitment and professionalism.

It's also crucial to check their production capabilities. Do they use modern technology? Are they able to handle complex designs? You may find that some manufacturers excel in specific processes, but lack flexibility. Be cautious about those who promise what they cannot deliver. Quality control processes should be transparent. A lack of clarity may indicate potential issues down the line.

Visiting the manufacturing facility can offer valuable insights. You can gauge the working environment and technology used. However, not everyone can visit. If that's the case, request customer testimonials. Past experiences can reveal strengths and weaknesses. Consider the overall value, not just the price. The cheapest option may not always be the best. Reflect on your requirements before making a decision.

How to Choose the Best PCB Manufacturing Process for Your Project?

| Criteria | Importance Level | Typical Lead Time | Cost Range (per board) | Volume Capability |

|---|---|---|---|---|

| Prototype Quality | High | 2-3 weeks | $50-$100 | Low to Medium |

| Production Volume | Medium | 1-2 weeks | $20-$50 | High |

| Complexity of Design | High | 3-4 weeks | $100-$300 | Medium |

| Material Selection | High | 1-3 weeks | $70-$150 | Medium |

| Customization Options | Medium | 2-3 weeks | $30-$80 | High |

Related Posts

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

Understanding the Future of Electronic Board Assembly in Modern Technology

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

10 Best Circuit PCB Manufacturing Services That Enhance Your Electronics Design Efficiency

-

Why Printed PCBs Are Essential for Modern Electronics Innovation