Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

2025 How to Choose the Best Circuit Board Components for Your Projects

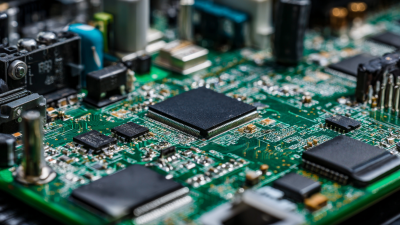

In the rapidly evolving landscape of electronics, the importance of selecting the right circuit board components cannot be overstated. According to a recent report by the Research and Markets, the global electronic components market is expected to reach $1.2 trillion by 2025, driven by the increasing demand for advanced technologies in various sectors, including consumer electronics, telecommunications, and automotive industries. This surge underscores the necessity for industries and engineers alike to make informed decisions when it comes to sourcing and integrating circuit board components.

As projects become more complex and tailored to specific applications, the challenge lies not just in choosing components that meet functional requirements, but also those that offer reliability, cost-effectiveness, and scalability. The IPC Association for Automated Industry Reports indicates that nearly 70% of product failures can be traced back to inadequate component selection. This statistic highlights the critical role that circuit board components play in ensuring both the longevity and performance of electronic devices. In this guide, we will delve into the top five considerations for selecting the best circuit board components for your projects, equipping you with the insights needed to navigate this intricate process successfully.

Table of Contents

[Hide]

Understanding the Essential Functionality of Circuit Board Components in 2025 Projects

In 2025, selecting the right circuit board components is crucial for the efficiency and functionality of electronic projects. Understanding the essential functions of each component is paramount. Resistors, for instance, control current flow and protect sensitive components from damage. Capacitors, on the other hand, store energy and help maintain voltage levels, making them vital for stable circuit operations. Knowing the roles of these components allows engineers to design circuits that will perform reliably under various conditions.

Moreover, advancements in technology have led to new components that offer improved performance and efficiency. For example, newer semiconductor materials can enhance signal processing speed and reduce power consumption. As projects increasingly demand higher performance and compact designs, choosing components that align with these requirements becomes even more critical. By staying abreast of the latest developments and understanding how these components interact, designers can create innovative solutions that meet the challenges of modern electronics.

Evaluating Component Reliability: Metrics and Standards for Longevity and Performance

When selecting circuit board components for your projects, evaluating the reliability of those components is crucial for ensuring longevity and performance. One of the key metrics to consider is the Mean Time Between Failures (MTBF), which indicates the expected operational time before a failure occurs. Components with a higher MTBF typically suggest better reliability, making them ideal for applications where durability is essential.

Furthermore, understanding the operational environment, such as temperature and humidity levels, can help in predicting how well a component will perform over time.

Furthermore, understanding the operational environment, such as temperature and humidity levels, can help in predicting how well a component will perform over time.

Another important standard to assess is the Qualification Testing Procedures, which include stress testing and lifecycle assessments. These tests provide insights into how components react under various conditions, leading to a more informed selection process. Certifications such as ISO 9001 and IPC standards also play a critical role, as they indicate that components have undergone rigorous quality checks.

By focusing on these metrics and standards, engineers can make informed decisions that enhance the overall performance and reliability of their circuit board designs.

Cost-Effectiveness in Component Selection: Balancing Quality and Budget Constraints

When selecting circuit board components in 2025, understanding cost-effectiveness is critical. According to industry benchmarks, the complexity of a mobile application can significantly influence its overall development cost. For instance, projects requiring advanced features such as AI integration may escalate costs by up to 30% compared to standard applications. Therefore, balancing quality and budget constraints necessitates a strategic approach to component sourcing, focusing on suppliers who offer long-term reliability and cost efficiencies.

Moreover, leveraging emerging trends in influencer marketing can provide insights into effective budget utilization. Reports indicate that brands allocating funds to micro-influencers in 2025 saw an average ROI increase of 20% due to their niche-targeted reach. Utilizing data from this segment can inform decisions on components and materials that not only meet technical specifications but also align with contemporary market demands, ultimately contributing to a project's success without exceeding the budget.

Designing effective cost control measures is also paramount in industries such as prefabricated construction. An analysis of cost impacts from design to application revealed that optimized logistics can reduce expenses by up to 15%. Therefore, integrating efficient planning and execution strategies will be essential in meeting budgetary goals while maintaining high-quality standards in circuit board component selection.

2025 Circuit Board Components Cost-Effectiveness Analysis

This chart displays the average costs of various essential circuit board components in 2025, helping you evaluate cost-effectiveness while keeping in mind quality for your projects.

Sustainability Considerations: Choosing Eco-Friendly Components for Modern Circuit Boards

In recent years, the electronics industry has witnessed a growing emphasis on sustainability, particularly concerning the components used in circuit board manufacturing. According to a report by the International Electronics Manufacturing Initiative (iNEMI), approximately 70% of electronic waste is generated by discarded circuit boards, leading to a pressing need for eco-friendly alternatives. Choosing sustainable components not only minimizes environmental impact but also enhances the social responsibility profile of manufacturers and designers.

Eco-friendly materials, such as bio-based plastics and lead-free solders, are rapidly gaining traction among industry professionals. A report by the Electronics Industry Citizenship Coalition (EICC) highlights that products utilizing these sustainable materials can reduce carbon footprints by up to 30%. Additionally, components designed for longevity and recyclability can significantly decrease waste generation and promote a circular economy. As manufacturers face increasing regulatory pressures and consumer demands for greener products, prioritizing eco-friendly components in project planning is not merely a trend; it is becoming an industry standard essential for future development.

2025 How to Choose the Best Circuit Board Components for Your Projects - Sustainability Considerations: Choosing Eco-Friendly Components for Modern Circuit Boards

| Component Type | Material | Eco-Friendly Rating | Recyclability | Energy Efficiency |

|---|---|---|---|---|

| Resistors | Carbon Film | A | Yes | Low |

| Capacitors | Aluminum | B | Yes | Moderate |

| Integrated Circuits | Silicon | C | No | High |

| PCBs | FR-4 | D | Partially | Low |

| Transistors | Organic | A+ | Yes | Very High |

Emerging Technologies: Integrating Advanced Circuit Board Components for Enhanced Performance

Emerging technologies are revolutionizing the way circuit board components are integrated into electronic projects, leading to unprecedented enhancements in performance. According to a recent report by MarketsandMarkets, the global printed circuit board market is projected to reach $80 billion by 2025, driven by advancements in high-frequency and high-speed materials used in modern circuitry. This surge in demand highlights the importance of selecting the right components to maximize efficiency and functionality in your projects.

As we explore advanced circuit board components, key trends such as the integration of flexible circuit technology and the use of advanced materials, like epoxy resin and polyimide, come into play. These materials not only allow for greater design flexibility but also enhance thermal management and signal integrity. A study by Research and Markets indicates that the flexible circuit market is expected to grow at a CAGR of 10.4% from 2020 to 2025, underscoring the shift towards versatility in circuit design. By incorporating these emerging technologies into your projects, you can achieve optimal performance and ultimately push the boundaries of innovation in your electronic designs.

Related Posts

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

10 Essential Tips for Designing High-Quality Printed PCB Boards Efficiently

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses

-

Understanding the Future of Electronic Board Assembly in Modern Technology