Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Choose the Right Wire Harness for Your Project in 2025

In the rapidly evolving world of technology, selecting the right wire harness for a project has become more crucial than ever. As we approach 2025, industry experts emphasize the importance of making informed decisions that align with both current standards and future needs. Renowned wire harness specialist, John Doe, states, "Choosing the appropriate wire harness is not just about compatibility; it’s about ensuring the longevity and reliability of your entire project." This insight highlights the complexities involved in wire harness selection, as various factors such as material, design, and application must be meticulously considered.

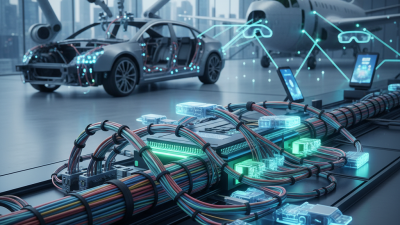

As electrical systems continue to grow in complexity and functionality, the wire harness serves as the vital connecting component between different elements of a project. It not only facilitates efficient electrical connections but also protects sensitive wires from environmental hazards. With advancements in technology and increasing demands for efficiency, understanding the nuances of wire harness design and assembly is essential for engineers and project managers alike. Thus, navigating this selection process effectively can lead to significant improvements in performance and durability for any project, underscoring the indispensable role of wire harnesses in modern applications.

Table of Contents

[Hide]

Understanding Wire Harness Basics and Components for Your Project

When embarking on a project that requires a wire harness, it's essential to understand the fundamental components and their functionalities. A wire harness is essentially a collection of wires, terminals, and connectors that work together to transmit electrical power and signals within various applications. Typically, wire harnesses are made from insulated wires bundled together, which not only organizes the wiring but also protects it from environmental factors and physical damage. Understanding the basic layout and design principles will set the groundwork for crafting a successful wire harness.

Key components of a wire harness include the wires themselves, which can vary in gauge and material depending on the project's power and data needs. Connectors are equally important, as they facilitate seamless connections between different electronic components. In addition, protective coverings, such as heat shrink tubing or conduit, help shield the wires from abrasion or moisture. Each of these elements must be carefully selected and aligned with the project's specific requirements to ensure optimal performance.

The considerations for selecting these components revolve around factors like electrical load, environmental conditions, and the overall functionality of the final product.

Identifying Your Project's Electrical Requirements and Specifications

When selecting a wire harness for your project in 2025, it's crucial to first identify the electrical requirements and specifications that will guide your decision. Begin by assessing the voltage, current, and overall power demand of your system. Understanding the operational environment is equally important; consider factors such as temperature fluctuations, exposure to moisture or chemicals, and vibration levels. This information will help you determine the appropriate wire gauge, insulation type, and harness configuration that can withstand these conditions effectively.

Additionally, consider the connectivity needs of your project. Identify the types and number of connections necessary, including connectors, terminals, and any additional components such as fuses or circuit breakers. Clear documentation of your electrical schema will facilitate a more accurate selection process. Planning for future scalability or modifications also plays a significant role. By anticipating potential changes in your project, you can choose a wire harness that accommodates future growth without compromising system integrity or safety.

How to Choose the Right Wire Harness for Your Project in 2025 - Identifying Your Project's Electrical Requirements and Specifications

| Wire Gauge | Maximum Current (A) | Voltage Rating (V) | Material | Insulation Type | Application |

|---|---|---|---|---|---|

| 18 AWG | 10 | 300 | Copper | PVC | Low Voltage Systems |

| 16 AWG | 13 | 600 | Copper | XLPE | Automotive Applications |

| 14 AWG | 15 | 600 | Copper | TPE | Power Distribution |

| 12 AWG | 20 | 600 | Copper | PVC | Heavy-duty Equipment |

| 10 AWG | 30 | 600 | Copper | EPDM | Industrial Machinery |

Evaluating Different Types of Wire Harnesses Available in 2025

In 2025, selecting the right wire harness for your project involves careful consideration of various types available in the market, each suited for different applications and environments. According to a recent industry report by MarketsandMarkets, the global wire harness market is projected to reach approximately $65 billion by 2025, growing at a CAGR of around 7.5%. This growth is primarily driven by advancements in automotive electronics and the increasing demand for efficient energy solutions in consumer electronics.

When evaluating wire harness types, it's crucial to understand their construction and application areas. For example, there are standard wire harnesses designed for basic electrical connections and more complex, custom wire harnesses that cater to unique specifications or challenging environments. The 2025 Industrial Wire Harness Market Report highlights the significance of flexible PVC and thermoplastic elastomer (TPE) materials, which enhance durability and resist environmental stressors, thereby improving the longevity of wire harnesses in various industries, including automotive and aerospace. Furthermore, the trend towards miniaturization necessitates harnesses that not only meet functional requirements but also adhere to space limitations, making the selection process even more critical for engineers and designers alike.

Assessing Quality and Durability Standards for Wire Harness Selection

When selecting a wire harness for your project, understanding and assessing quality and durability standards is essential. First, consider the material composition of the wire harness. High-quality materials, such as silicone or PVC, offer better insulation and resistance to environmental factors. Look for specifications that detail temperature ranges, chemical resistance, and mechanical properties. Wire harnesses should meet industry standards, such as UL or RoHS compliance, which ensure they are safe, reliable, and environmentally friendly.

Furthermore, durability is influenced by the manufacturing processes and testing procedures employed. It’s critical to evaluate whether the wire harness has undergone rigorous testing for tensile strength, abrasion resistance, and resistance to flex fatigue. Ask about the quality control measures in place during production, as consistent quality assurance can significantly impact the lifespan of the harness. Finally, consider the application of the wire harness; specific projects may require additional features, such as enhanced waterproofing or EMI shielding, which can further ensure performance and durability in demanding environments.

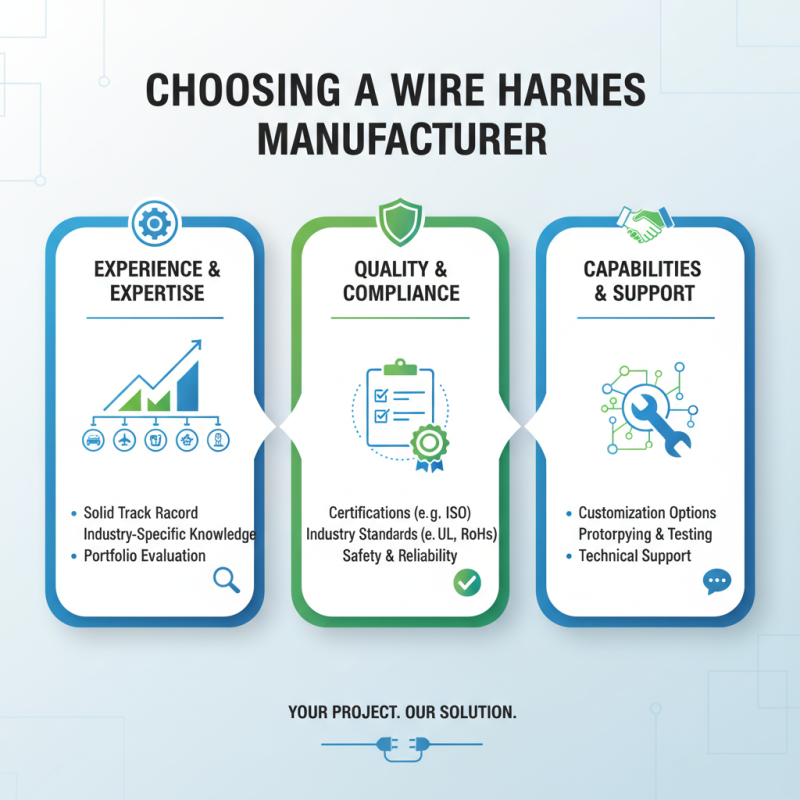

Choosing the Right Manufacturer or Supplier for Your Wire Harness Needs

When selecting the right manufacturer or supplier for your wire harness needs, it’s essential to consider their experience and expertise in the field. A reputable manufacturer should have a solid track record in producing wire harnesses tailored to various industries, ensuring that they understand the specific requirements of your project. Evaluate their portfolio to see examples of previous work, as this can provide insight into their capabilities and level of craftsmanship. Additionally, assess their certifications and compliance with industry standards, as this indicates a commitment to quality and safety.

Communication and customer service are also crucial factors when choosing a wire harness supplier. A reliable manufacturer should be responsive to inquiries and willing to collaborate throughout the design and production processes. Effective communication helps to clarify project specifications and timelines, reducing the risk of misunderstandings and delays. Furthermore, consider their ability to offer customized solutions. The best suppliers will work with you to understand the unique challenges of your project and provide innovative approaches that meet your specific wiring requirements.

Related Posts

-

Top 2025 Wire Harness Trends: Innovations and Essential Applications

-

How to Choose the Right Cable Harness for Your 2025 Project Needs

-

Top 10 Essential Tips for Efficient Wire Harness Assembly Processes

-

10 Essential Tips for Successful Circuit Board Design

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses

-

2025 How to Choose the Best Circuit Board Components for Your Projects