Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Choose the Right Electronic Board Assembly Process for Your Project

In the rapidly evolving landscape of electronics manufacturing, the choice of the right electronic board assembly process is crucial to the success of any project. According to a report by industry analysts, the global printed circuit board (PCB) assembly market is projected to reach USD 77.6 billion by 2025, growing at a CAGR of 3.9%. This increase highlights the growing demand for efficient and reliable electronic board assembly methods that meet various project requirements, ensuring high-quality production and reducing time-to-market.

Selecting the appropriate electronic board assembly process involves a careful evaluation of several factors, including the complexity of the design, production volume, and budget constraints. An industry white paper indicates that approximately 70% of assembly defects can be traced back to poor process selection, emphasizing the importance of making informed decisions. Additionally, advancements in automation and emerging technologies are reshaping electronic board assembly practices, enabling manufacturers to achieve higher accuracy and efficiency. Making the right choice not only impacts production quality but also influences the long-term viability and competitiveness of the product in a saturated market.

Table of Contents

[Hide]

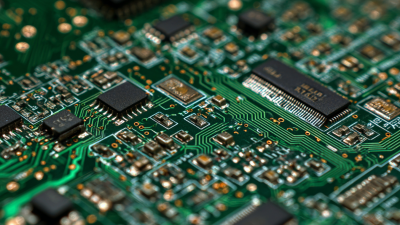

Understanding Electronic Board Assembly Processes

When embarking on an electronic board assembly (EBA) project, understanding the various assembly processes is crucial for ensuring the success and efficiency of your production. Common methods include surface mount technology (SMT) and through-hole technology (THT), each offering distinct advantages based on the project's requirements. SMT is favored for its compactness and efficiency, making it ideal for high-density designs, while THT provides robust connections which are preferable for larger components or when durability is a key concern.

Tips: Consider the scale of your project. For mass production, investing in automated SMT can significantly reduce labor costs and improve consistency. However, for small batches or prototypes, manual assembly might be more practical and cost-effective.

Another important aspect to consider is the complexity of your board design. Boards with intricate layouts typically benefit from advanced assembly processes that incorporate sophisticated technologies like automated optical inspection (AOI) and reflow soldering. These methods enhance the accuracy and quality of the assembly, minimizing the risk of defects.

Tips: Always prioritize testing and validation in your assembly process. Implementing a thorough testing phase can catch potential issues early, preventing costly revisions later in the production cycle.

Assessing Your Project Requirements and Specifications

When selecting an electronic board assembly process for your project, it is crucial to evaluate your specific requirements and specifications. Start by understanding the complexity of your design. For instance, if your project involves intricate components and high-density placements, a surface mount technology (SMT) assembly may be the best fit. Conversely, if your design features larger components or requires through-hole technology, it’s essential to consider that as well. The choice of technology impacts not only the assembly process but also the overall cost and timeline of your project.

**Tips:** Assess the volume of production needed. For low-volume or prototype projects, a more manual assembly process may suffice, allowing for flexibility and modifications as designs evolve. In contrast, high-volume projects will benefit from automated assembly processes, which ensure consistency and speed. Additionally, always account for testing and quality assurance – ensuring that your assembly process aligns with the necessary compliance standards is critical.

Lastly, consider the materials and components you will be using. Different assembly techniques may have preferences for specific types of materials, and understanding these can prevent compatibility issues down the line. Engage with your team to develop a robust project specification document that outlines all critical parameters, which will guide your decision-making in the assembly process choice.

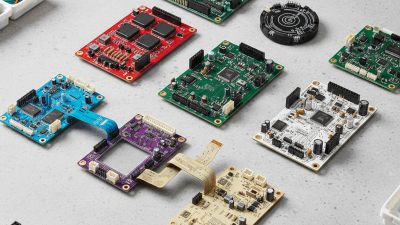

How to Choose the Right Electronic Board Assembly Process for Your Project

| Project Type | Volume Requirements | Complexity Level | Preferred Assembly Method | Budget |

|---|---|---|---|---|

| Consumer Electronics | High Volume | Moderate | Surface Mount Technology (SMT) | Medium |

| Medical Devices | Low to Medium Volume | High | Through-Hole Technology (THT) | High |

| Automotive Electronics | Medium Volume | High | Mixed Technology | Medium to High |

| Industrial Equipment | Low Volume | Moderate | Manual Assembly | Medium |

| Aerospace | Low Volume | Very High | Custom Assembly | Very High |

Evaluating Different Assembly Methods: Pros and Cons

When evaluating different electronic board assembly methods for your project, it's crucial to weigh the pros and cons of each approach carefully. For instance, Manual Assembly can be a cost-effective solution for small production runs or prototypes, offering flexibility and precision that machine-based processes may lack. However, it tends to be slower and may introduce a higher likelihood of human error, especially in the absence of rigorous quality control measures. According to a 2022 IPC report, nearly 30% of defects in assembled boards stem from human assembly errors, highlighting this method's potential drawbacks.

On the other hand, Automated Assembly methods, including Surface Mount Technology (SMT) and Through-Hole Technology (THT), provide speed and consistency, essential for larger production volumes. The same IPC report suggests that manufacturers utilizing automated processes can reduce assembly times by 60% compared to manual methods. However, the initial investment in automated equipment can be substantial, potentially ranging from $100,000 to over $1 million, depending on the complexity of the machinery. Additionally, while automated processes reduce human error, they may still require skilled technicians for setup and maintenance, balancing cost versus efficiency and expertise needed throughout the production lifecycle.

Ultimately, the choice of assembly method should be driven by the specific requirements of your project, including volume, complexity, and budget, ensuring that the selected process aligns strategically with your long-term goals.

Comparison of Electronic Board Assembly Methods

This chart compares the cost per unit for different electronic board assembly methods, highlighting the pros and cons associated with each method. Manual assembly has the highest cost, whereas wave soldering is more economical. Reflow soldering, while effective, incurs higher costs compared to selective soldering.

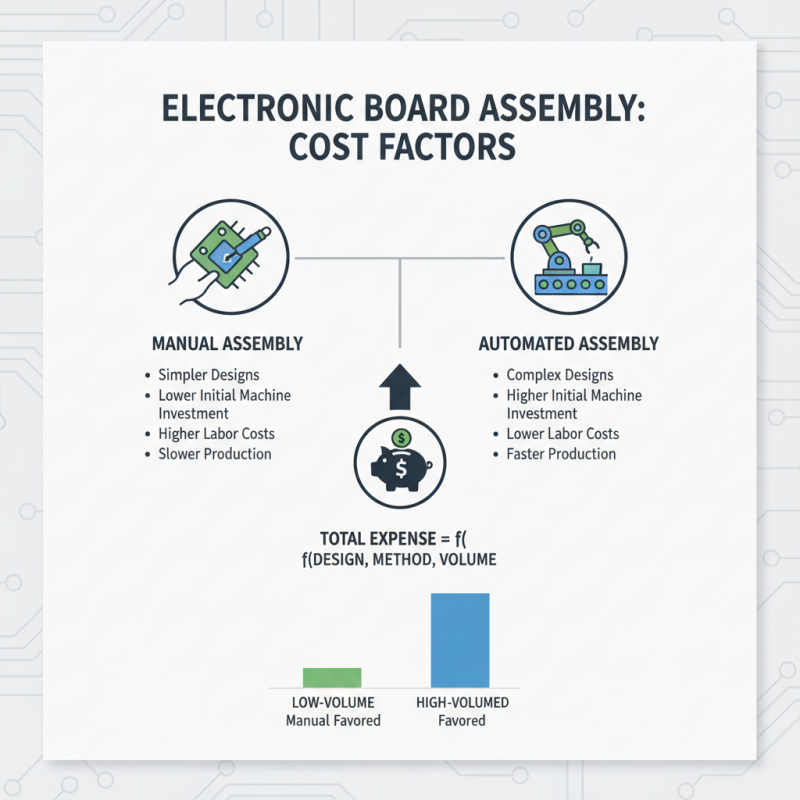

Cost Considerations in Electronic Board Assembly

When embarking on an electronic board assembly project, cost considerations are paramount. The total expense can be influenced by various factors, including the complexity of the design, the choice between manual and automated assembly, and the volume of production. For simpler designs, manual assembly might be a feasible option, as it often requires less upfront investment in machinery; however, it can lead to higher labor costs. On the other hand, automated processes might have higher initial cost implications but can significantly reduce labor costs and increase production speed in the long run.

Tips: Always perform a detailed cost analysis, taking into account both upfront and long-term operational costs. Consider how the assembly method will impact the overall budget and timeline, ensuring the chosen process aligns with your project's financial constraints.

Additionally, sourcing materials wisely can lead to significant savings. Bulk purchasing and establishing relationships with suppliers can minimize costs. It's also critical to assess potential hidden costs that can arise from design errors or delays in the assembly process. Investing in a thorough prototype phase can reveal design flaws early, preventing more costly corrections during full-scale production.

Tips: Don’t overlook the total cost of ownership when calculating expenses. Factor in delivery times, storage, and potential rework costs that may emerge during the assembly. This comprehensive approach will help ensure your project remains within budget while meeting quality standards.

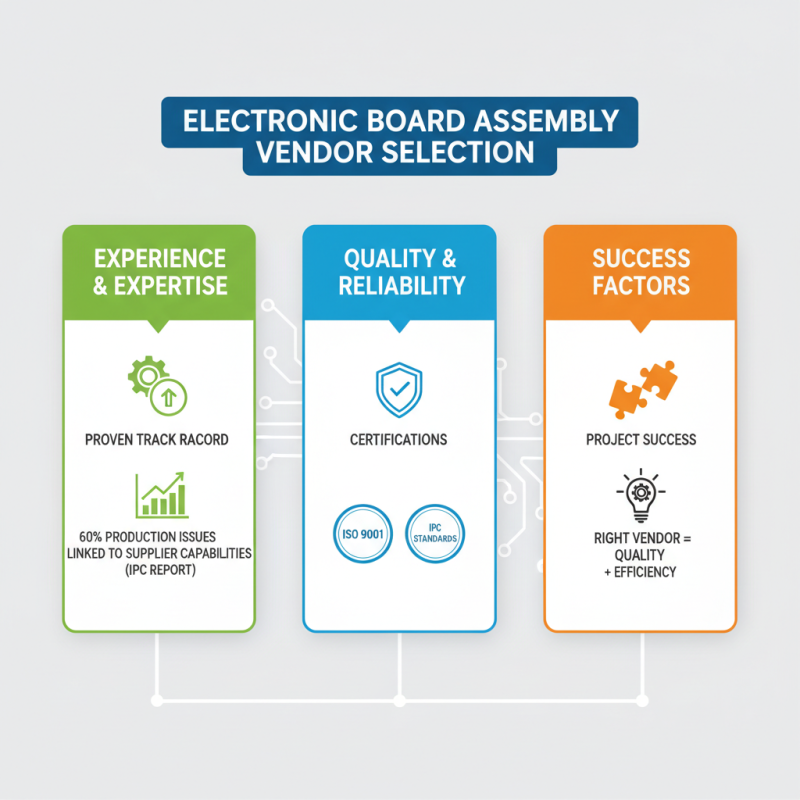

Selecting the Right Vendor for Your Assembly Needs

When selecting the right vendor for your electronic board assembly needs, it’s crucial to consider several key factors that can greatly impact the success of your project. One important aspect is the vendor's experience and expertise in the specific type of assembly process you require. According to a report by IPC, a leading industry association for electronics manufacturing, nearly 60% of production issues are linked to supplier capabilities, highlighting the importance of choosing a vendor with a proven track record in similar projects. Prioritizing vendors with relevant certifications, such as ISO 9001 and IPC standards, can help ensure high quality and reliability in the assembly process.

Additionally, evaluate the vendor's ability to scale production based on your project requirements. A survey conducted by Statista revealed that 75% of electronics manufacturers cited scalability as a top concern when choosing assembly partners. It's essential to work with a vendor that can accommodate both small-scale prototypes and larger production runs without compromising quality or lead times. Engaging in discussions regarding their production capacity and flexibility can help you identify a partner capable of meeting your evolving needs as your project progresses. By thoroughly assessing these factors, you’ll be better positioned to select a vendor that aligns with your assembly goals and contributes to the overall success of your project.

Related Posts

-

Why Printed Board Assembly is Essential for Modern Electronics Manufacturing

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

Why Printed PCBs Are Essential for Modern Electronics Innovation

-

Understanding the Future of Printed Circuit Technology in Everyday Devices

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Top 10 Printed PCB Board Types for Your Electronics Projects