Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

10 Best Circuit PCB Manufacturing Services That Enhance Your Electronics Design Efficiency

In the rapidly evolving world of electronics, the demand for high-quality circuit PCB (Printed Circuit Board) manufacturing services has never been greater. According to recent reports from industry analysts, the global PCB market is projected to reach approximately $83 billion by 2025, driven by advancements in technology and increasing consumer electronics consumption. This surge is prompting designers and engineers to seek efficient manufacturing solutions that not only enhance design capabilities but also streamline production processes.

As the complexity of electronic devices increases, so does the necessity for precision and reliability in circuit PCB production. Factors such as miniaturization, high-frequency performance, and integration of smart technologies further underline the importance of selecting the right manufacturing partner. In this context, top-tier circuit PCB manufacturing services play a crucial role in accelerating the design cycle and ensuring product success in a competitive marketplace.

To navigate this landscape effectively, it is essential to identify the best circuit PCB manufacturing services that align with modern design requirements. This article highlights the top 10 circuit PCB manufacturers, evaluating their capabilities in meeting the demands of today's electronics design environment while delivering optimal efficiency and quality.

Table of Contents

[Hide]

Top Circuit PCB Manufacturing Services Revolutionizing Design Processes in 2025

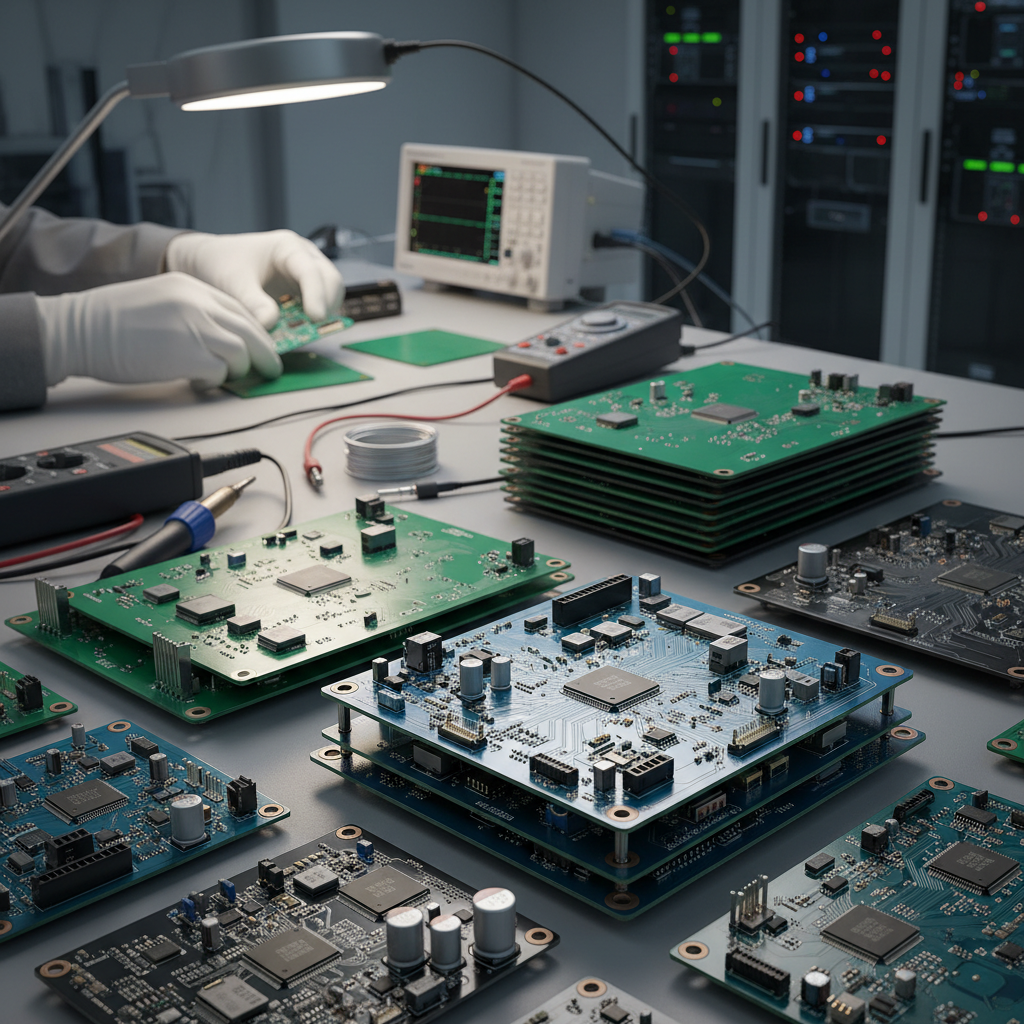

In 2025, the landscape of circuit PCB manufacturing services has undergone a revolutionary transformation, driven by technological advancements and a relentless pursuit of efficiency. The most innovative services now employ cutting-edge software solutions for design automation, which significantly reduces lead times and minimizes errors. By integrating AI-driven design tools, engineers can quickly iterate on their concepts, ensuring that the final product meets stringent specifications while optimizing material usage.

Moreover, enhanced collaboration platforms have emerged, allowing designers and manufacturers to work seamlessly across geographic boundaries. These platforms offer real-time feedback and support, enabling teams to address challenges promptly and enhance the overall communication process. As a result, companies can bring their electronic designs to market faster than ever, ensuring they stay ahead in a competitive environment characterized by rapid technological change and escalating customer demands. The evolution of these PCB manufacturing services is not just about speed; it is fundamentally reshaping how engineers approach their projects, fostering innovation and creativity in electronic design.

Key Features to Look for in PCB Manufacturing Services for Enhanced Efficiency

When choosing a PCB manufacturing service, several key features can significantly enhance your electronics design efficiency. Firstly, the capability for rapid prototyping is crucial. According to a report by IPC, manufacturers that offer quick-turn services can reduce prototyping time by up to 70%. This speed not only accelerates the design cycle but also allows for more iterative testing, an essential aspect of modern electronic development.

Another vital feature is the availability of advanced manufacturing technology. A study by the Electronics Industry Association highlights that companies employing state-of-the-art machinery can achieve up to 99.9% yield rates. This high precision minimizes waste and rework, directly impacting the overall cost-efficiency of the production process. Additionally, effective communication channels and robust customer support systems can greatly streamline project management, enabling design teams to focus on innovation rather than logistical challenges.

Lastly, look for manufacturers that prioritize quality control through rigorous testing and certification processes. The importance of compliance with industry standards, such as ISO 9001, cannot be overstated, as it ensures reliability and performance in the final product. Data shows that 60% of companies report fewer failures by utilizing services that adhere to stringent quality measures, underscoring the need for conscientious procurement in PCB manufacturing.

PCB Manufacturing Services Efficiency Comparison

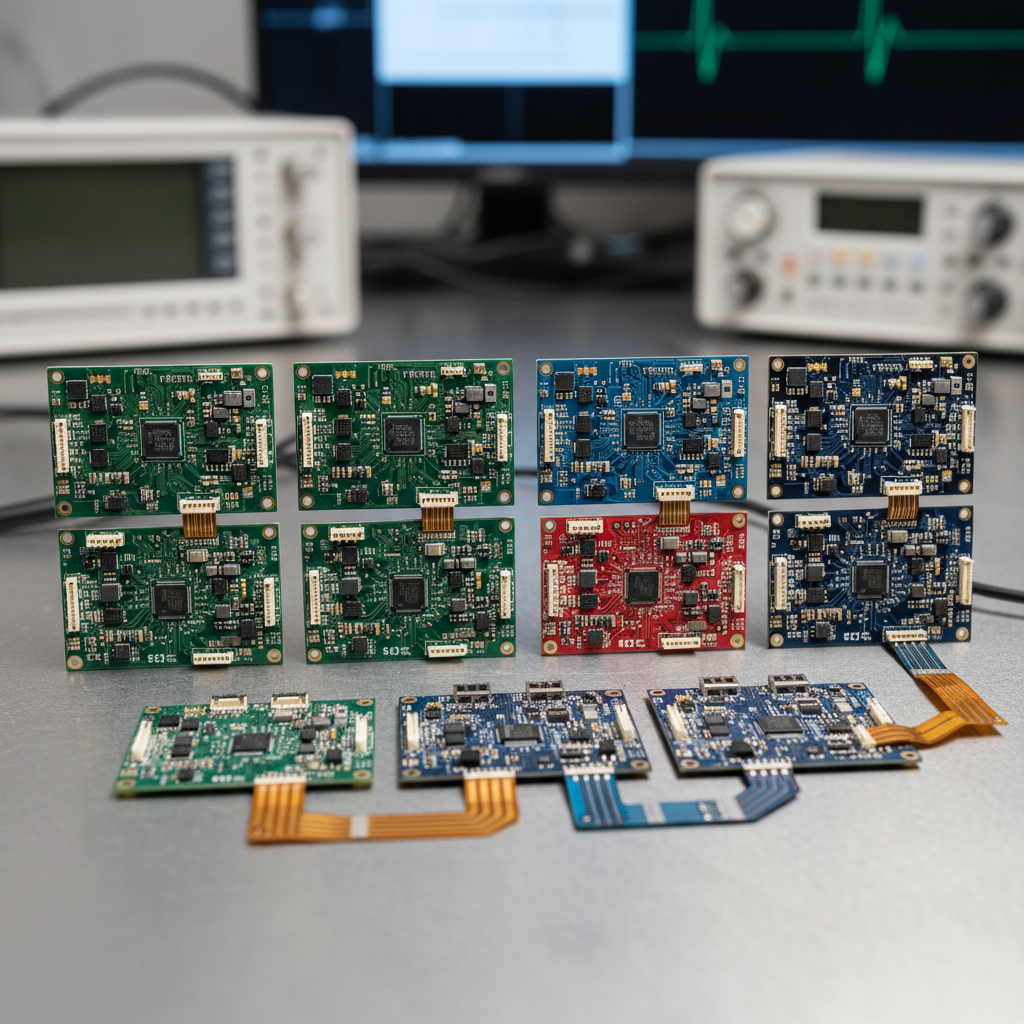

Comparative Analysis of Leading PCB Manufacturers in 2025

As the global printed circuit board (PCB) market grows from $715.7 billion in 2024 to an estimated $741.2 billion in 2025, manufacturers are adopting innovative solutions to enhance design efficiency. The trajectory reflects a significant transformation in the industry, driven by advancements in automation and digitalization.

A comparative analysis of leading PCB manufacturers reveals that companies are emphasizing the integration of software solutions to streamline design and manufacturing processes. Siemens' recent acquisition of a design and manufacturing data preparation solution provider underscores the trend of large firms investing in technologies that foster efficiency and collaboration in the workflow.

Tips: When choosing a PCB manufacturer, consider their capabilities in handling complex designs, as well as how they incorporate technology into their processes. Additionally, examining their track record in meeting deadlines and quality standards can provide insights into their reliability. Always keep an eye on market trends, as emerging technologies can reshape the competitive landscape significantly.

Innovative Technologies Transforming PCB Production and Design Collaboration

The landscape of PCB manufacturing is rapidly evolving, thanks to innovative technologies that significantly enhance design collaboration and production efficiency. One key advancement is the integration of automated design tools, which according to a report from industry analysts, can reduce design time by up to 50%. This transformation allows designers and engineers to iterate more rapidly, identifying and resolving potential issues early in the development cycle. The implementation of AI-driven design software, such as Autodesk's EAGLE, optimizes layouts and component placements, reducing errors and saving valuable resources.

Moreover, the rise of cloud-based manufacturing platforms fosters greater collaboration among teams located anywhere in the world. A survey by the IPC indicates that over 70% of electronics companies now utilize cloud solutions for PCB design and production. This shift not only streamlines communication but also enables real-time updates, which is essential for maintaining project timelines in a competitive market. Enhanced collaboration tools allow cross-functional teams to work cohesively, ensuring that electronic designs are produced efficiently while meeting the highest quality standards. As the industry embraces these technological advancements, electronic designs become increasingly sophisticated, paving the way for the next generation of innovative products.

10 Best Circuit PCB Manufacturing Services That Enhance Your Electronics Design Efficiency

| Service Provider | Max PCB Size (inches) | Layers Supported | Lead Time (Days) | Minimum Order Quantity |

|---|---|---|---|---|

| Provider A | 12 x 18 | 1-32 | 7 | 5 |

| Provider B | 10 x 15 | 1-16 | 10 | 10 |

| Provider C | 8 x 12 | 1-4 | 5 | 20 |

| Provider D | 15 x 20 | 1-6 | 14 | 2 |

| Provider E | 10 x 14 | 1-8 | 12 | 15 |

Customer Testimonials: Real-world Impact of Top PCB Services on Project Outcomes

Choosing the right circuit PCB manufacturing service can significantly impact your electronics design projects. Customer testimonials showcase real-world experiences, highlighting how top PCB services have led to enhanced efficiency and improved project outcomes. Many users report that high-quality manufacturing and responsive customer service are key factors in meeting tight deadlines and reducing costly errors. For instance, one customer praised a service for its precision and timely delivery, allowing their team to focus more on innovation rather than troubleshooting manufacturing issues.

When selecting a PCB service, consider the following tips to maximize your project’s success. First, evaluate the provider's production capabilities to ensure they can handle your specific requirements, whether it’s for prototypes or large-scale production. Next, seek out customer reviews and case studies to understand how well a service has performed in comparable projects. Lastly, maintain open lines of communication with the service provider throughout your project, as this can help address potential issues before they escalate, fostering a collaborative environment that enhances overall efficiency.

Related Posts

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms

-

The Future of Electronics: How PCB and Assembly Technology is Shaping Tomorrow's Devices

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

The Future of Wire Harness Manufacturing Trends Innovations and Sustainability Practices

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners