Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top 10 Best Circuit Card Assembly Techniques for Efficient Production

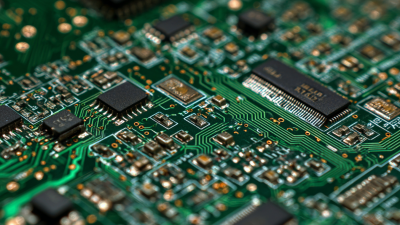

In the world of electronics, circuit card assembly plays a crucial role. Efficient production techniques can significantly enhance the manufacturing process. This article presents the top ten methods used in circuit card assembly to optimize performance.

Choosing the right technique can be challenging. Scope for improvement is often overlooked. By analyzing current practices, manufacturers can adopt more effective strategies. For instance, automating certain processes can reduce human error. However, it is vital to balance automation with quality checks.

Learning from past mistakes is essential for progress. Some engineers focus too much on speed rather than precision. Circuit card assembly requires a blend of both. Attention to detail can lead to fewer defects and longer product lifespans. Continuous evaluation and adaptation are keys to achieving optimal results in this evolving industry.

Table of Contents

[Hide]

Overview of Circuit Card Assembly Techniques

When it comes to Circuit Card Assembly (CCA) techniques, efficiency is key. Different methods can lead to varying production rates and quality outcomes. Automated soldering is one technique that has gained popularity. It significantly reduces manual labor. However, it requires precise setup and calibration. Without proper management, it may lead to defects.

Another technique is surface mount technology (SMT). SMT allows for smaller components and higher density. While this increases production efficiency, it can complicate repairs. Mistakes in placement can occur, resulting in costly rework. Operators must be well-trained to prevent these issues.

Finally, inspection processes, such as Automated Optical Inspection (AOI), are vital. These ensure that circuits meet quality standards. Yet, relying solely on automated inspections can overlook subtle flaws. A combination of both automated and manual inspections often yields better results. The balance between speed and meticulousness is essential in CCA.

Top 10 Best Circuit Card Assembly Techniques for Efficient Production

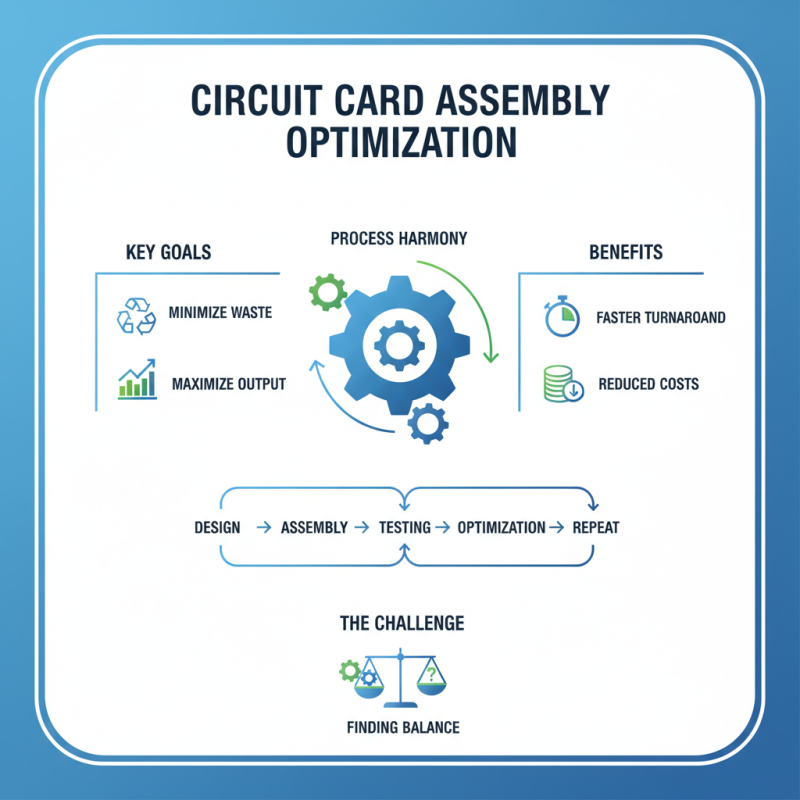

Importance of Process Optimization in Circuit Card Assembly

In the world of circuit card assembly, process optimization is crucial. Efficient production relies on minimizing waste and maximizing output. Every element of the assembly process must work in harmony to achieve these goals. A well-optimized process can lead to faster turnaround times and reduced costs. However, many manufacturers struggle with finding the right balance.

Training staff is a key aspect often overlooked. Workers need to understand their roles thoroughly. A trained team can identify bottlenecks quickly. On the other hand, miscommunication can lead to errors. Small mistakes can escalate, resulting in significant delays. Regular training sessions can help maintain high standards and improve performance.

Adopting modern technologies can also enhance production efficiency. Automated systems may seem like a solution, but they require careful integration. Not every aspect of assembly should be automated. Sometimes, human intuition is essential. After all, technology can fail, leading to costly downtime. Organizations must reflect on their methods consistently. Continuous improvement is essential for success.

Common Challenges in Circuit Card Assembly Production

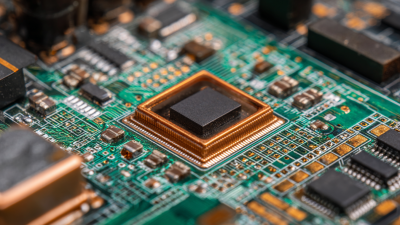

Circuit card assembly (CCA) production faces several challenges that can impact efficiency. One common issue is the handling of delicate components. A recent survey shows that around 30% of assembly errors stem from mishandling parts. Misalignment can lead to costly rework. Accuracy during the placement of components is crucial for maintaining production speed and quality.

Another challenge is the complexity of modern designs. With increasing miniaturization, the density of circuit boards has surged. This complexity can result in difficulties during soldering and inspection. According to industry reports, nearly 25% of manufacturers experience delays due to inspection failures. Many processes rely heavily on visual checks, which can be prone to human error. Limited automation in these stages further exacerbates these issues.

Supply chain disruptions also contribute to inefficiencies in CCA production. Fluctuations in component availability can halt operations. About 40% of production teams report delays linked to sourcing issues. This problem highlights the need for robust supply chain management strategies. As these challenges persist, looking for innovative solutions becomes essential. Continuous improvement efforts will play a vital role in overcoming these hurdles.

Top 10 Best Circuit Card Assembly Techniques for Efficient Production - Common Challenges in Circuit Card Assembly Production

| Technique | Description | Common Challenges | Efficiency Improvement |

|---|---|---|---|

| Surface Mount Technology (SMT) | Automated placement of electronic components on the surface of PCBs. | Placement misalignment and solderability issues. | High-speed production and reduced space usage. |

| Through-Hole Technology (THT) | Components are inserted through holes and soldered on the opposite side. | Manual insertion errors and lengthy soldering times. | Strong mechanical connections for high-stress applications. |

| Mixed Technology | Combines SMT and THT for design flexibility. | Complex assembly and testing requirements. | Enhanced functionality in compact designs. |

| Automated Optical Inspection (AOI) | Uses camera systems to verify assembly integrity. | False positives and missed defects. | Rapid defect detection and improved quality assurance. |

| Wave Soldering | Flooding molten solder over PCB for THT components. | Thermal damage to components. | Efficient for large batches of assemblies. |

| Selective Soldering | Targeted soldering of specific connections. | Higher upfront costs and setup time. | Reduced solder waste and improved accuracy. |

| Reflow Soldering | Heating solder paste with an infrared or convection system. | Temperature control issues causing solder defects. | High throughput with minimal manual intervention. |

| Design for Manufacturability (DFM) | Design approach to simplify assembly and reduce costs. | Collaboration challenges between design and production teams. | Reduced assembly time and lower waste. |

| Flexible Manufacturing Systems (FMS) | Adaptable production systems for varied product types. | Higher initial investment and need for skilled operators. | Increase in production flexibility and efficiency. |

| Lean Manufacturing Practices | Eliminating waste and optimizing processes. | Cultural resistance and employee training. | Shorter lead times and improved productivity. |

Key Techniques for Enhancing Circuit Card Assembly Efficiency

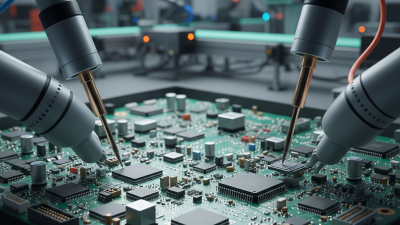

Efficient circuit card assembly significantly impacts production quality and cost. Several key techniques can enhance this process. Automation is a primary technique. By utilizing automated machines, one can achieve faster assembly with greater accuracy. These machines can handle repetitive tasks, reducing human error. However, automation requires a significant initial investment and training.

Another effective technique is the use of modular assembly. This allows for easy upgrades and replacements. It streamlines the assembly process by enabling teams to work on different components simultaneously. While modular design offers flexibility, it can complicate the overall system if not planned carefully. Balancing simplicity with functionality is crucial.

Additionally, regular training of assembly staff is essential. Knowledgeable workers can identify and address issues promptly. They can also optimize their workflow for better productivity. Yet, over-reliance on skilled workers can lead to disruptions if turnover occurs. Continuous assessment of team skills is necessary to maintain efficiency. Focusing on these key techniques leads to improved production while acknowledging the associated challenges.

Future Trends in Circuit Card Assembly Methods

The landscape of circuit card assembly (CCA) is rapidly evolving. Advanced automation technologies are transforming production lines. A recent industry report from IPC indicates that over 70% of manufacturers are adopting automated solutions to increase efficiency. These technologies promise faster assembly times and reduced human error. However, the learning curve is steep. Many companies struggle to integrate these systems effectively.

Sustainable practices are also shaping future trends. A study by the Electronics Industry Citizenship Coalition reveals that 55% of firms are prioritizing eco-friendly materials. This shift can lead to challenges in sourcing. Not all manufacturers are ready to adapt to new regulations on materials. Moreover, while this commitment to sustainability is commendable, it may initially inflate production costs.

Additionally, the rise of smart devices influences assembly techniques. Data from Statista shows a projected growth in the market for smart electronic devices by 25% over the next five years. This boom demands versatile assembly methods. However, manufacturers face pressure to keep pace with rapid technological advancements. Short product lifecycles can lead to frequent redesigns, complicating the assembly process.

Related Posts

-

Top 10 Benefits of Circuit Board Assembly for Modern Electronics?

-

Understanding the Future of Printed Circuit Technology in Everyday Devices

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

Why Circuit Board Manufacturing Is Essential for Modern Technology Development

-

How to Choose the Right Electronic Board Assembly Process for Your Project

-

Why Choosing the Right PCB and Assembly Process is Crucial for Your Project?