Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top 10 Benefits of Circuit Board Assembly for Modern Electronics?

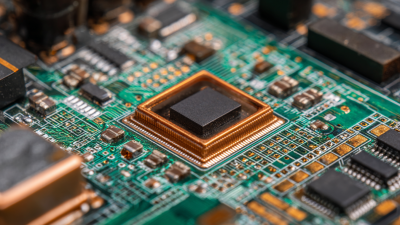

The landscape of modern electronics is constantly evolving, fundamentally shaped by advancements in circuit board assembly. According to industry reports, the global PCB market is expected to reach over $100 billion by 2025, reflecting a continuous demand for efficient assembly processes. This growth is driven by the increasing complexity of electronic devices, where precise circuit board assembly is crucial.

Companies are leveraging innovative assembly techniques to enhance product functionality and reduce costs. For instance, automated assembly processes improve production speed and accuracy. Yet, this shift also raises concerns about quality control and potential shortages of skilled labor. Balancing speed and quality remains a significant challenge for manufacturers.

As the electronics sector expands, circuit board assembly plays a pivotal role in enabling new technologies. High-quality assembly ensures reliable performance in everything from smartphones to medical devices. The need for continuous improvement in assembly practices is evident, as businesses strive to maintain competitiveness in this dynamic environment.

Table of Contents

[Hide]

Advantages of Streamlined Production Processes in Circuit Board Assembly

Streamlined production processes in circuit board assembly offer numerous benefits for modern electronics. Efficiency is significantly improved. Automated systems reduce human error and speed up assembly. This means faster turnaround times for products. Companies can respond quickly to market demands. With quicker assembly, they can launch products sooner.

Additionally, streamlined processes lower costs. Production waste is minimized. This helps maintain budget constraints. Fewer mistakes lead to less rework, which can be costly. However, achieving this can be challenging. Organizations may need to invest in new technology. Old methods might be deeply ingrained, making change difficult.

Quality also benefits from smoother processes. Tighter controls ensure each board meets standards. Consistent quality is essential for device reliability. Yet, companies must be vigilant. Over-reliance on automation could overlook potential defects. Regular assessments are necessary to maintain high standards. Balancing efficiency and craftsmanship is key.

Top 10 Benefits of Circuit Board Assembly for Modern Electronics

| Benefit | Description | Impact |

|---|---|---|

| Cost Efficiency | Reduced labor and material costs through streamlined processes. | Higher profit margins for manufacturers. |

| Increased Throughput | Faster production cycles enable higher output. | Ability to meet market demands promptly. |

| Quality Control | Enhanced testing and inspection techniques ensure high standards. | Reduced defect rates and increased customer satisfaction. |

| Design Flexibility | Ability to adapt designs quickly to meet demands. | Faster time to market for new products. |

| Scalability | Easier to scale production for increasing volume requirements. | Efficient expansion in response to market growth. |

| Innovative Technologies | Integration of advanced manufacturing techniques and materials. | Enhanced performance of electronic devices. |

| Automation | Use of automated systems to increase precision. | Reduced labor costs and improved accuracy in assembly. |

| Sustainability | Efforts to reduce waste and improve recycling processes. | Positive environmental impact and brand image. |

| Enhanced Collaboration | Improved communication among design and production teams. | Faster resolution of issues and more innovative solutions. |

| Global Sourcing | Leverage of global suppliers for cost-effective materials. | Cost savings and diversified supply chains. |

Enhancing Product Reliability Through Quality Circuit Board Assembly Standards

High-quality circuit board assembly standards are essential in today's electronics landscape. A report from IPC states that 60% of electronics failures stem from poor assembly practices. This underscores the importance of reliable manufacturing processes. Standards ensure consistency in assembling components with minimal defects. When companies adhere to these protocols, they significantly boost the reliability of their products.

Enhanced product reliability often translates to higher customer satisfaction. A study revealed that products built with high assembly standards experience 30% fewer returns. This is crucial for maintaining a company's reputation. However, not all manufacturers prioritize quality. Some overlook the necessity of rigorous testing and inspection, which can lead to long-term issues. While embracing quality standards might seem expensive initially, it ultimately saves costs.

The evolution of assembly technology plays a role too. Automated assembly has improved precision. Yet, human oversight remains vital in quality control. Continuous training for assembly personnel can bridge the gap. A well-trained workforce can adapt to new processes, ensuring the longevity of products. Manufacturers must reflect on their practices to enhance reliability and drive innovation.

Top 10 Benefits of Circuit Board Assembly for Modern Electronics

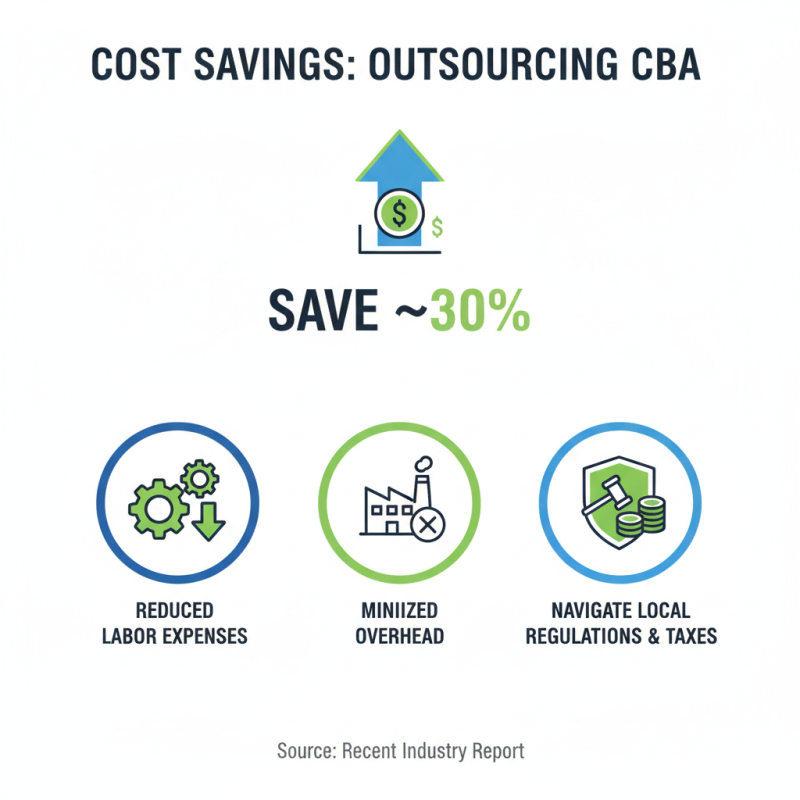

Cost-Effectiveness of Outsourcing Circuit Board Assembly Services

Outsourcing circuit board assembly (CBA) services can significantly reduce costs for electronics manufacturers. According to a recent report, firms save approximately 30% by outsourcing. This cost-effectiveness stems from reduced labor expenses and minimized overhead. Many companies also find that local regulations and taxes impact in-house assembly costs.

Quality is another factor. Outsourcing allows access to specialized expertise. Reports indicate that 75% of companies experience improved assembly quality when using third-party services. These experts often utilize advanced technologies, which lower error rates. This can lead to better product reliability in the market, a major selling point for electronics brands.

Tip: Research potential assembly partners thoroughly. Check their certifications and reviews. This can ensure your product meets quality standards. Consider starting with smaller orders to gauge their performance before committing fully. Engaging with multiple suppliers can also provide insights into pricing and capabilities. Balancing cost with quality is essential for long-term success.

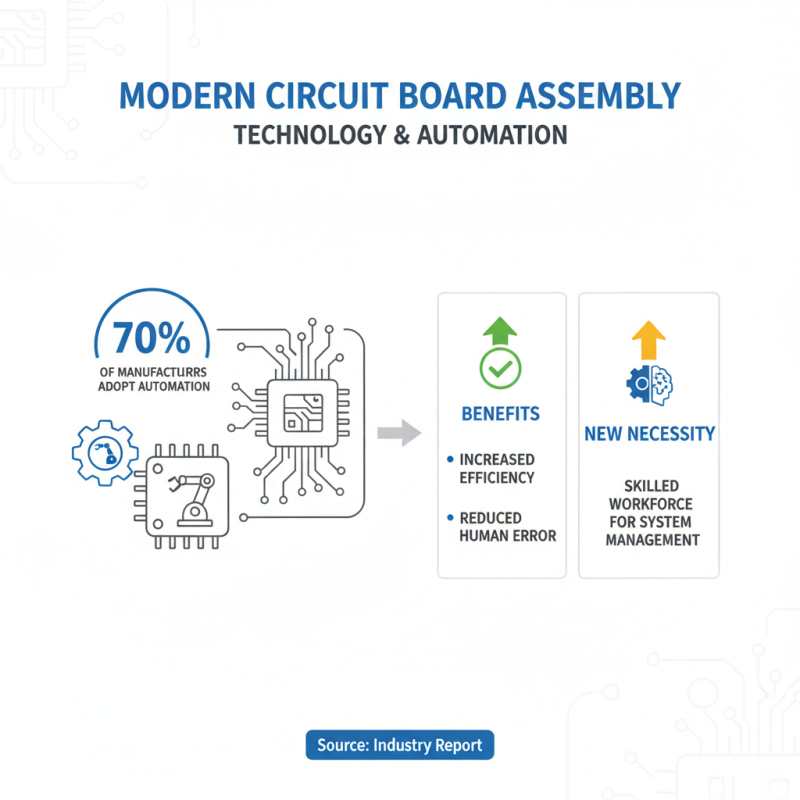

Integration of Advanced Technologies in Modern Circuit Board Assembly

The integration of advanced technologies in modern circuit board assembly is transforming the electronics landscape. Automation plays a key role. According to a recent industry report, nearly 70% of board manufacturers are adopting automated processes. Automation increases efficiency and reduces human error. Yet, it also necessitates a skilled workforce to manage these systems.

Advanced technologies like AI and IoT are also reshaping assembly processes. They enable predictive maintenance, which can reduce downtime by up to 30%. This is a significant improvement, but not without challenges. Many companies struggle with the initial investment and the learning curve. Furthermore, integrating these technologies can sometimes lead to compatibility issues within existing systems.

Another aspect is the rise of miniaturization in circuit boards. Smaller components can lead to complex assembly challenges. A study found that 20% of defects arise during this process. This highlights the need for precision and quality control. While there are numerous benefits, the industry's rapid evolution also raises critical questions about sustainability and resource management.

Environmental Benefits of Efficient Circuit Board Manufacturing Practices

Efficient circuit board manufacturing practices bring significant environmental benefits. By utilizing advanced technology, manufacturers can reduce waste. This leads to lower energy consumption. For instance, optimized production lines minimize excess material use. Such improvements also cut down on harmful emissions.

Moreover, recycling plays a crucial role in circuit board assembly. Many components can be reclaimed and reused. This initiative reduces landfill waste. However, recycling processes can be complex and not always effective. Achieving a truly circular economy in electronics requires ongoing effort.

Additionally, efficient manufacturing reduces the overall carbon footprint. Implementing energy-efficient machines is one strategy. Switching to renewable energy sources can further enhance sustainability. Yet, the transition might face obstacles. Not all facilities are capable of adopting these practices swiftly. Embracing these changes is necessary but imperfect. Continuous reflection and adaptation will be key in the journey toward greener electronic products.

Related Posts

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

How to Choose the Right Electronic Board Assembly Process for Your Project

-

2025 Guide: How to Master Circuit Board Design for Beginners

-

Top 10 Tips for Effective Circuit Board Design Strategies?

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics